-

Posts

1,579 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by redneckrigger

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Glosson C-O 4070A

redneckrigger replied to DRIPTROIT 71's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looks great Brian. Love the IH cabovers. BTW, my workbench is absolutely infested with squirrels! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Cutting Sheet Stock Accurately & Easy

redneckrigger replied to redneckrigger's topic in Tips, Tricks, and Tutorials

This sure is an oldie, as is it's little brother also shown here. Got both of them in an antique shop for $20 for the pair. With the scratchbuilding I do, it has become priceless. And, yup, it could make me into a three fingered Tom in a heartbeat! But I like my fingers attached to my hands, so I am VERY careful. And, yes it does cut sheet aluminum as well as brass. When I do thin brass and aluminum with it, I use a "cover sheet" which is just a heavy steel ruler, that I put over the part still on the cutting board, right up against the blade and hold pressure on it over the sheet. This helps me prevent curling of the edge of the cut. All in all a VERY handy tool -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IH Paystar 5000 4x4

redneckrigger replied to DRIPTROIT 71's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looking superb Brian. Those tires are great.................KFS has been sold and is supposed to resume production under the new owner in March. Hope they still carry those tires! Glad to see it under way again! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

M-715 Pickup

redneckrigger replied to Chariots of Fire's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Looking great Charlie! Those are neat trucks. The 230 CI OHC 6 cyl. Tornado engines in them were problematic. Had one in a 1965 civilian Wagoneer panel van...........was a dog from day one! You have already nailed the look with those fenders. Beautiful! -

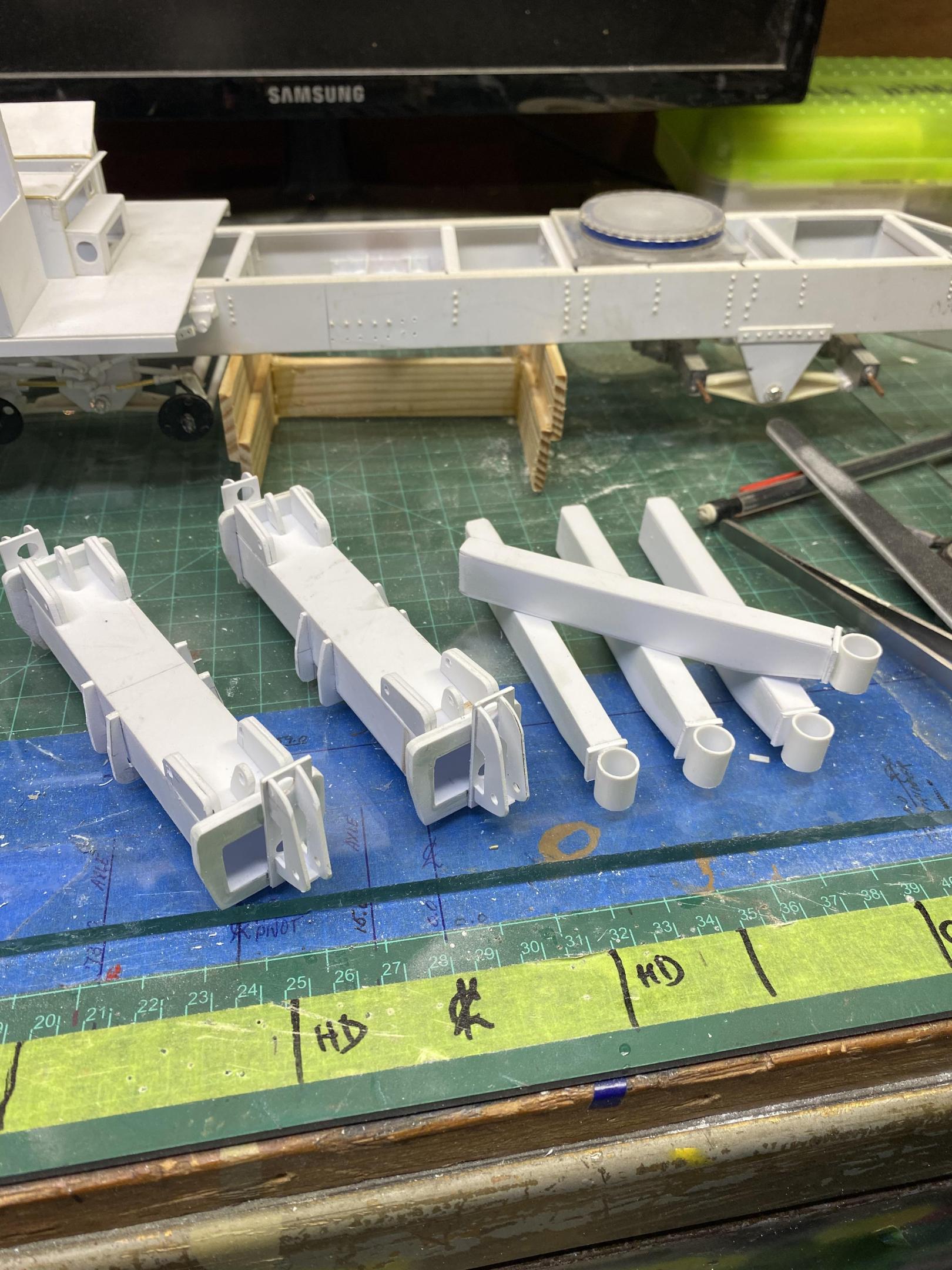

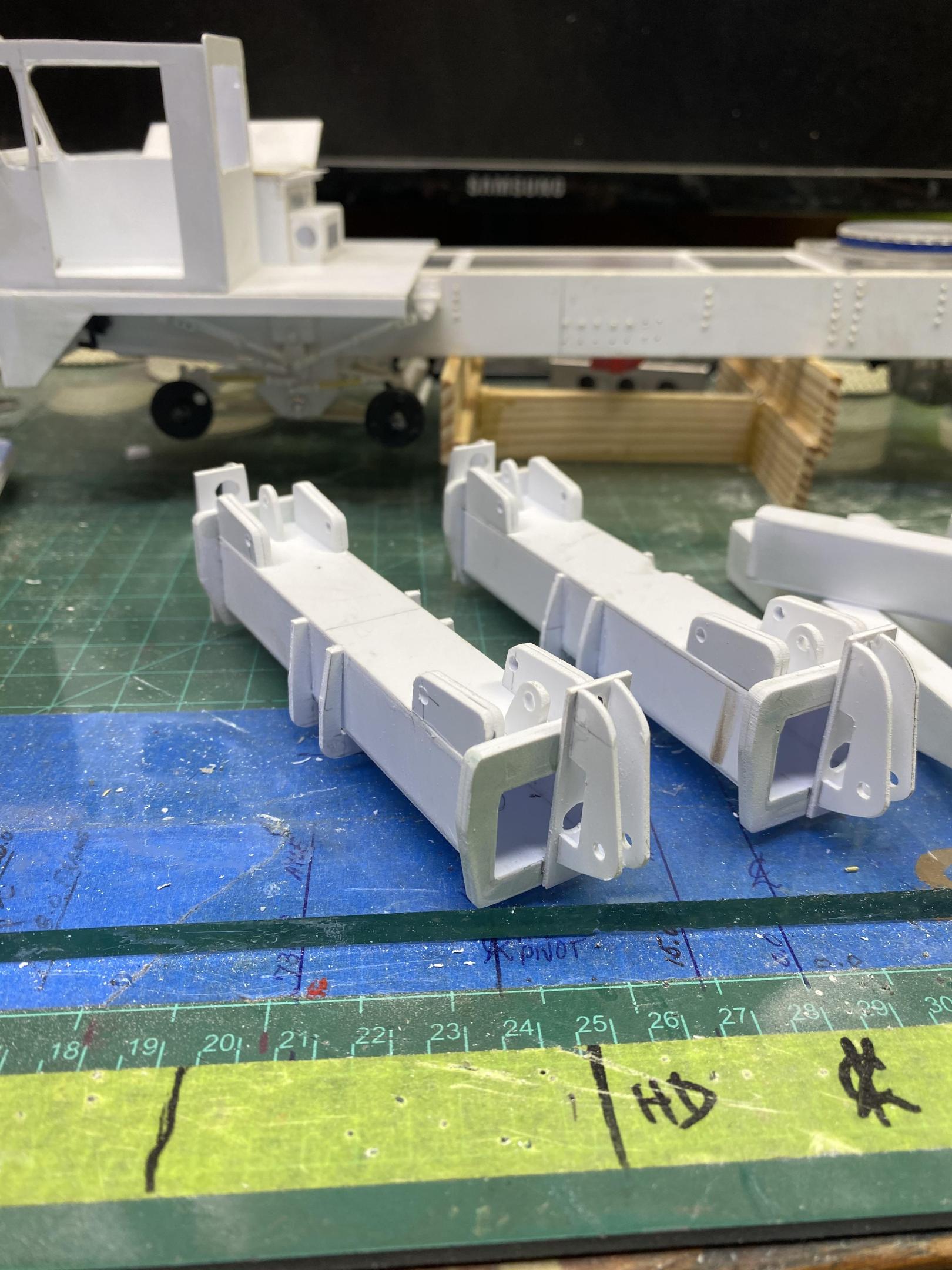

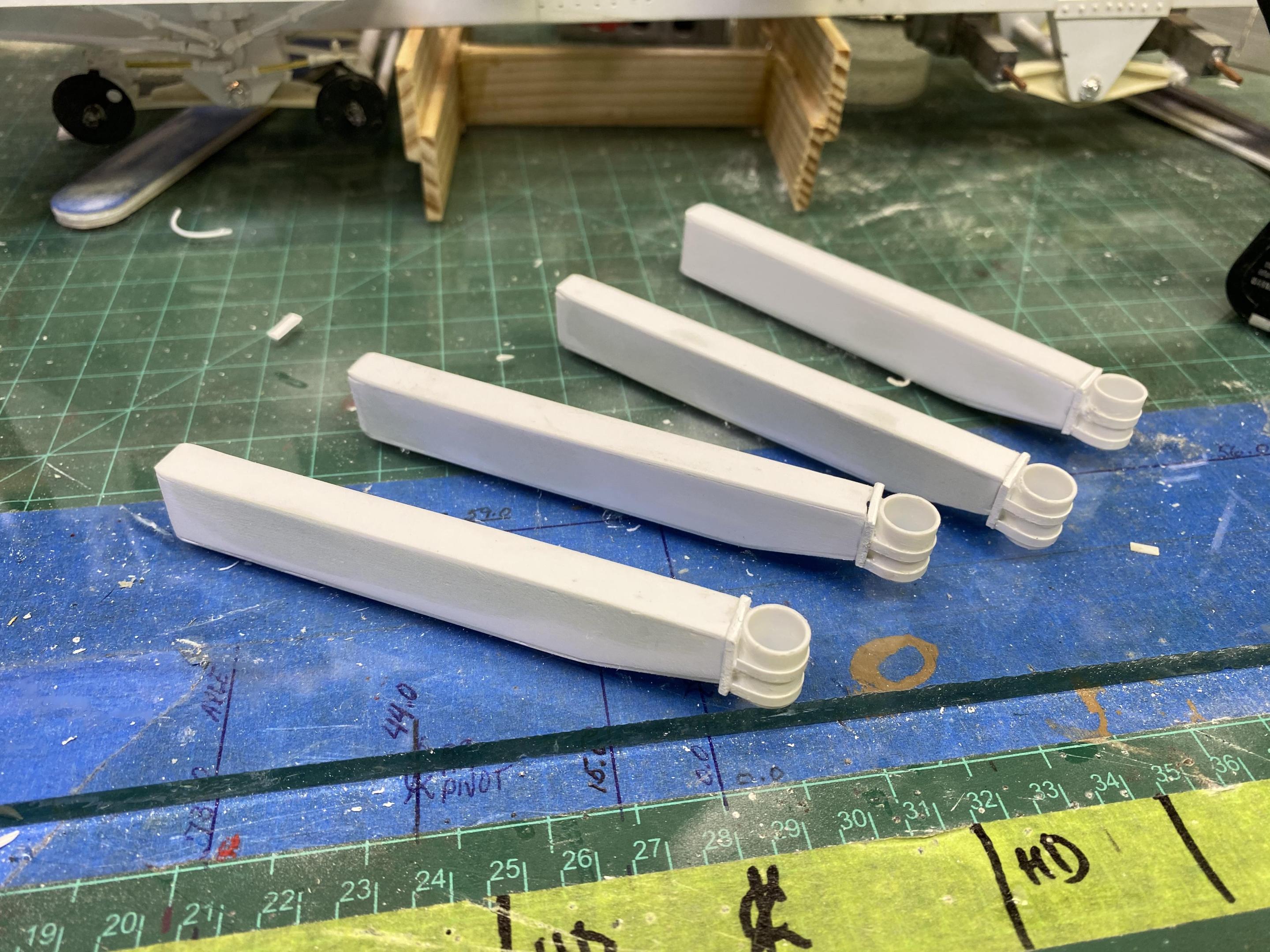

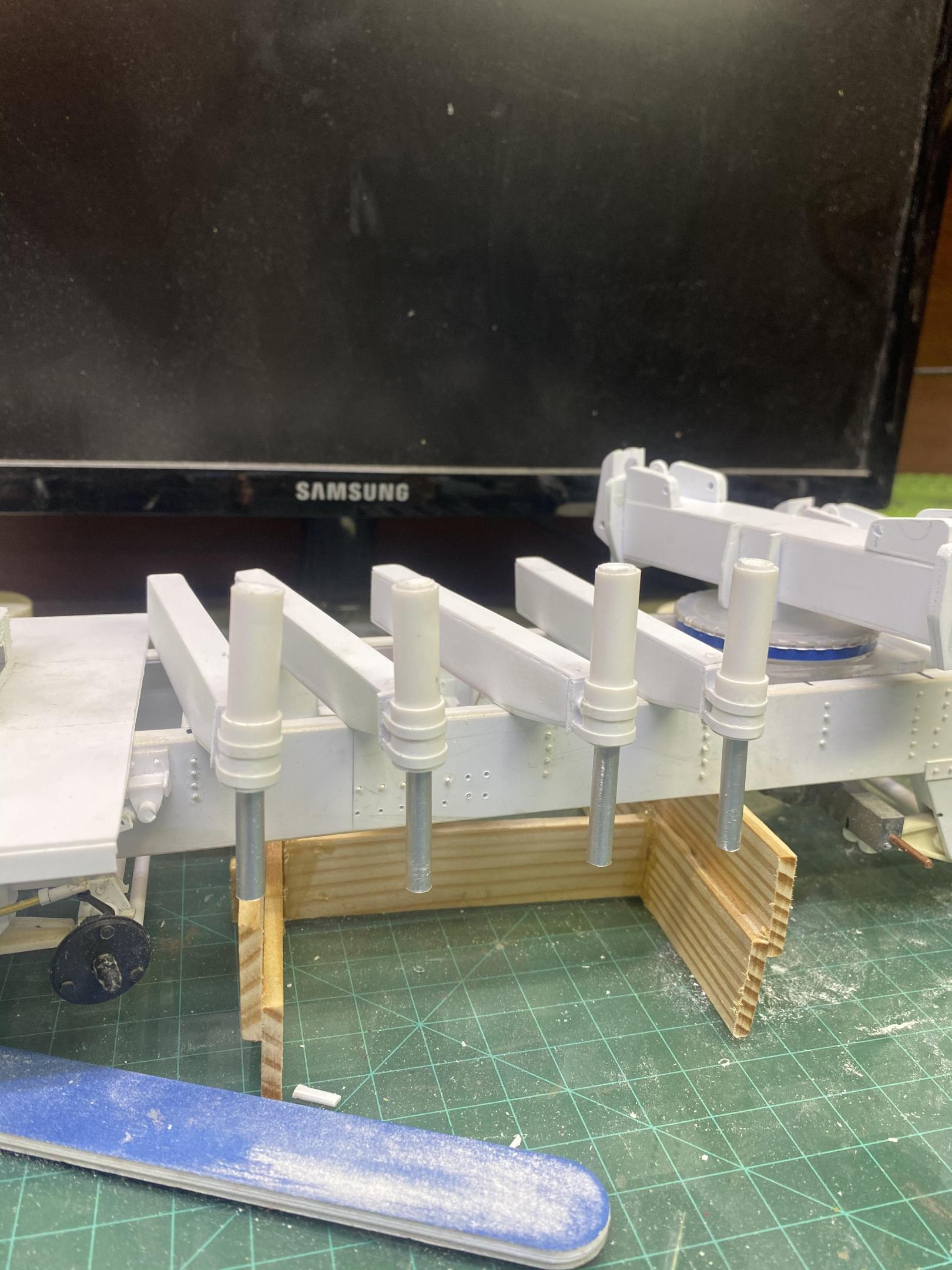

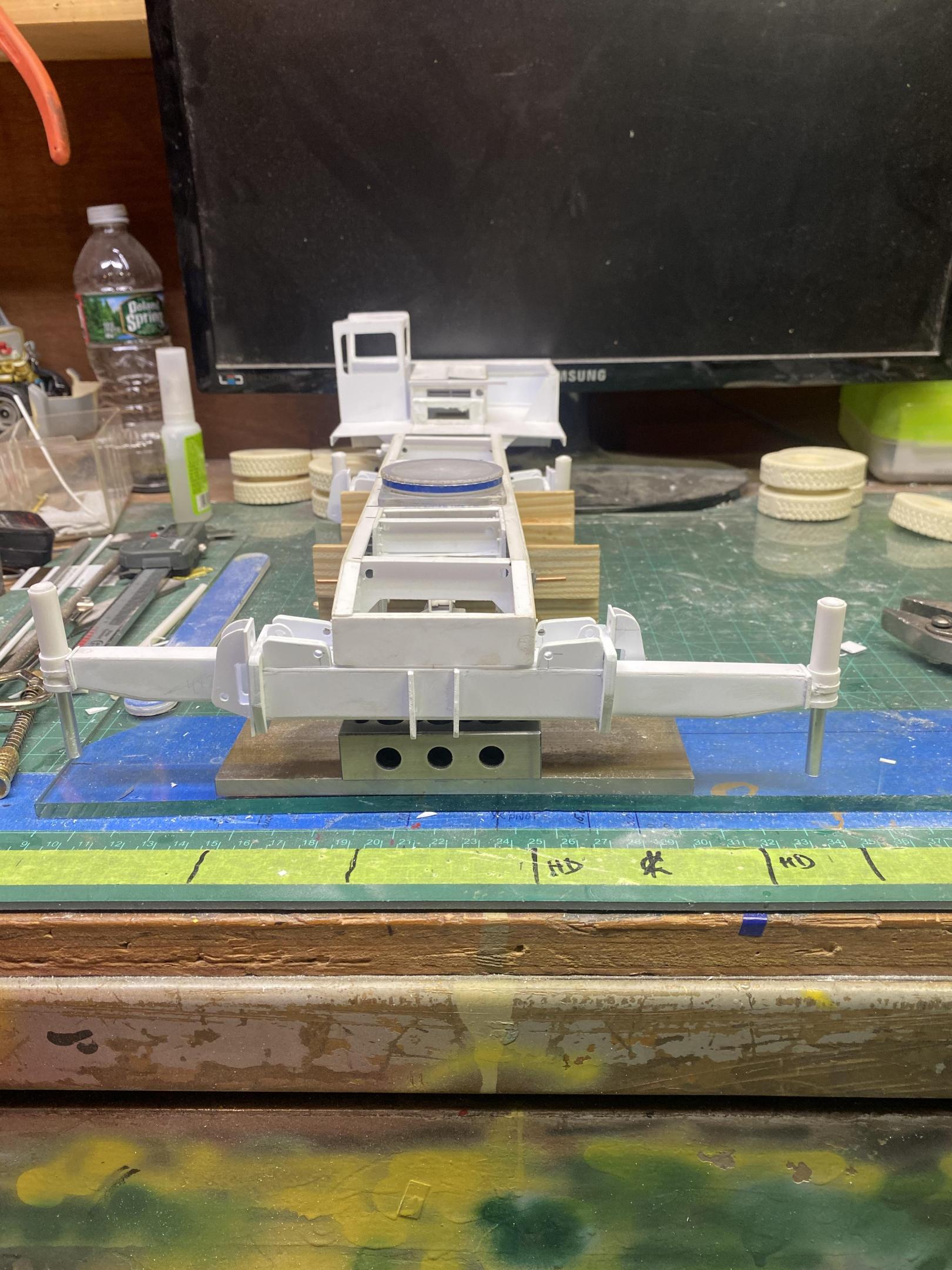

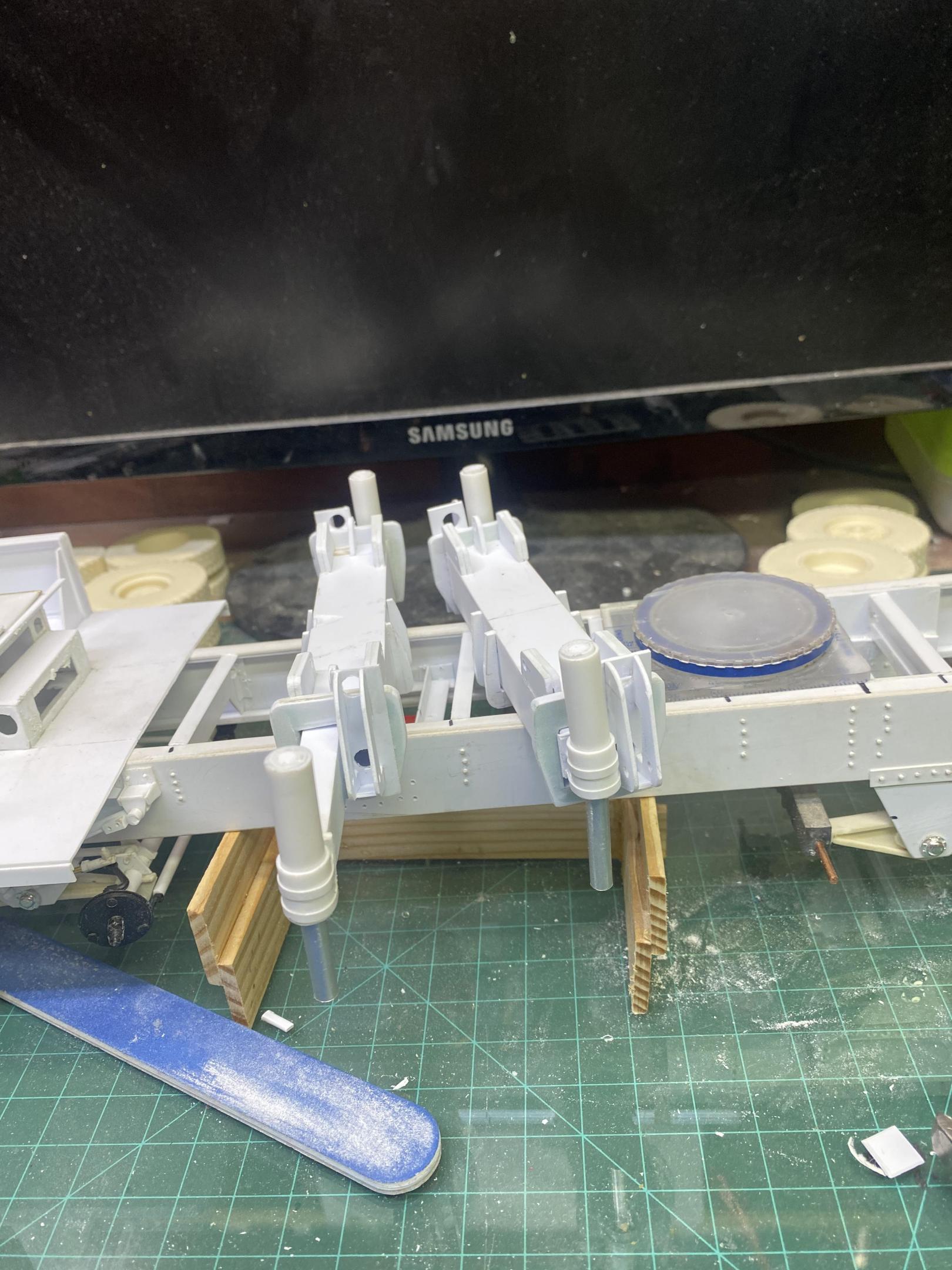

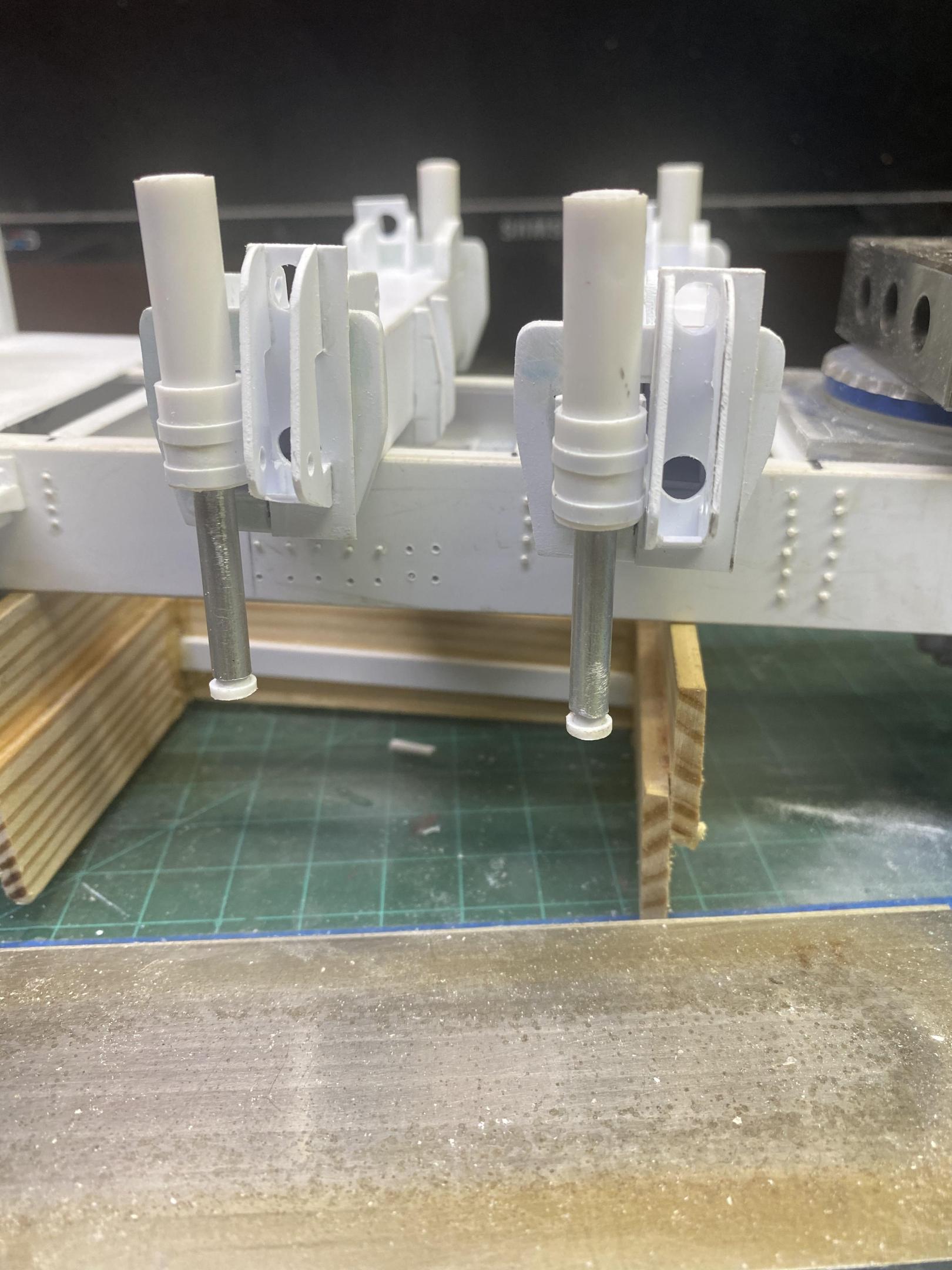

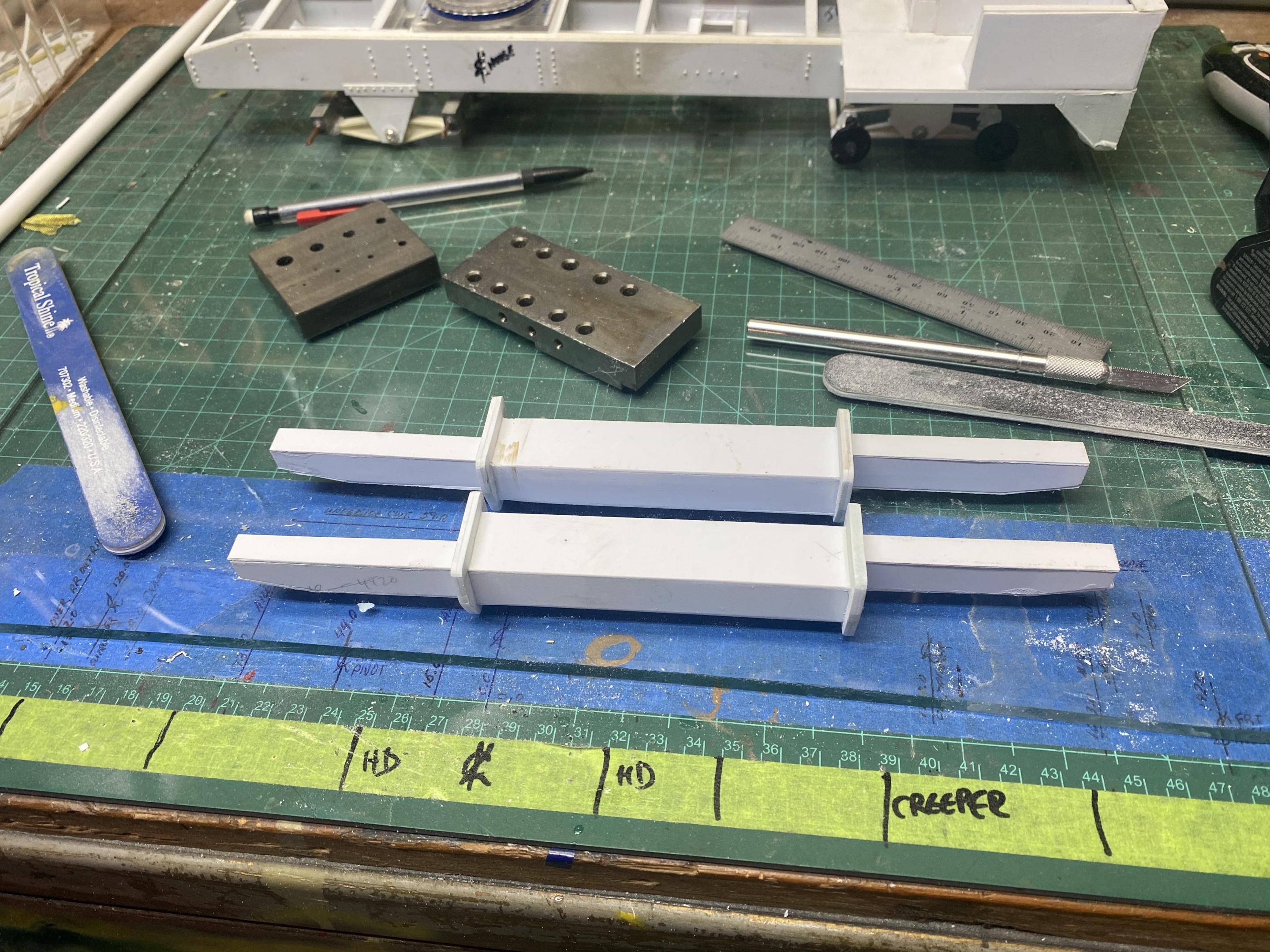

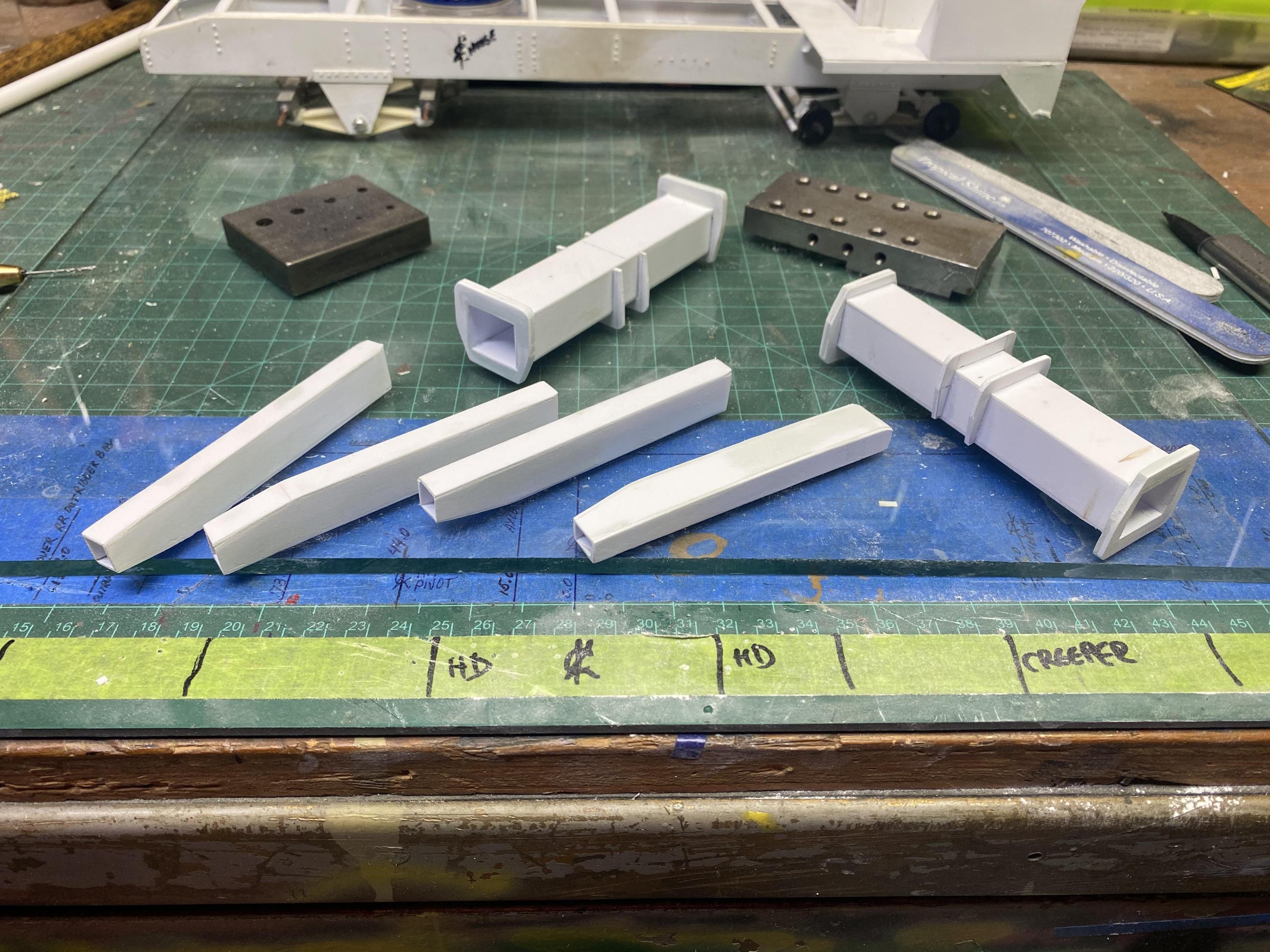

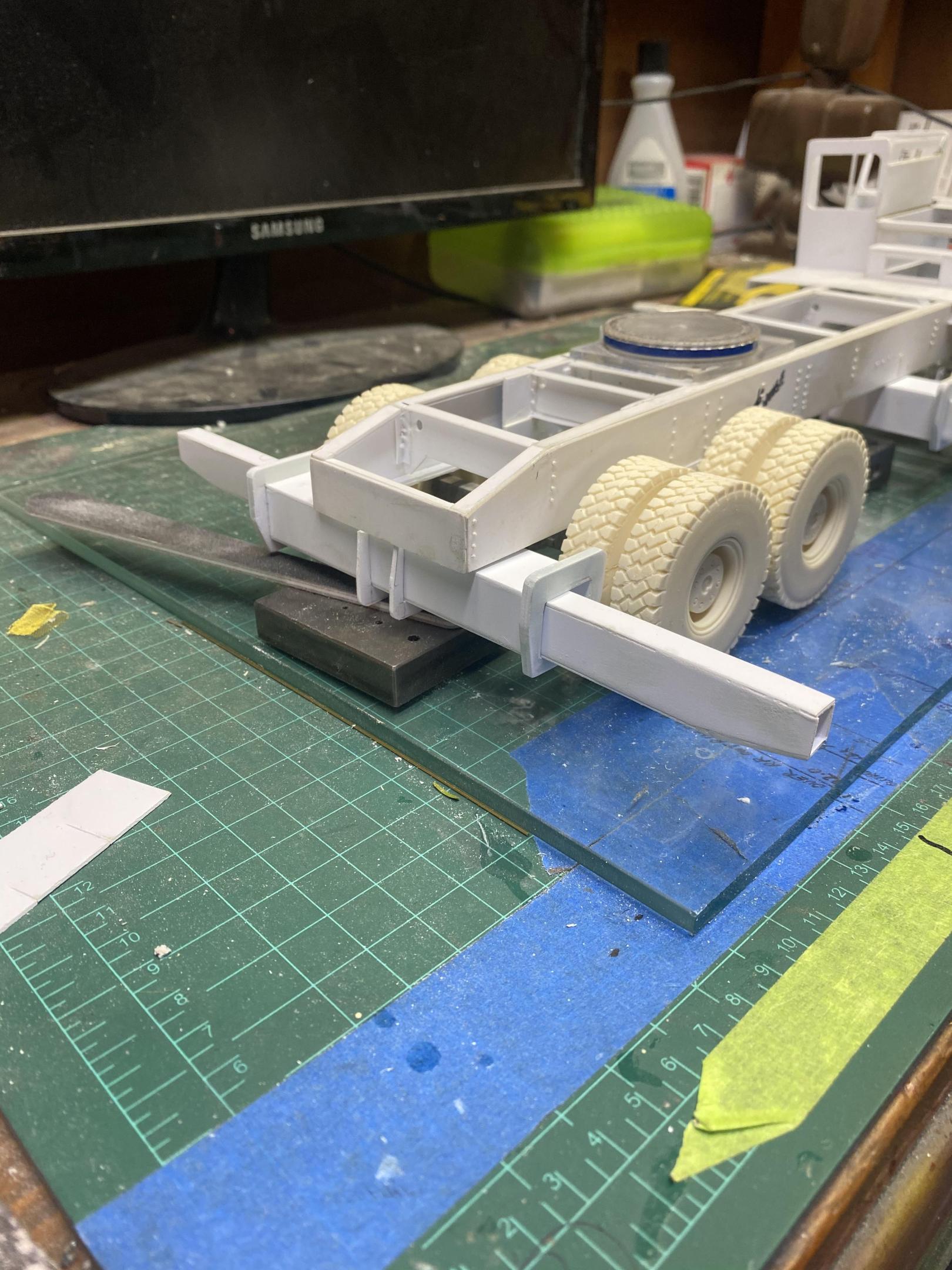

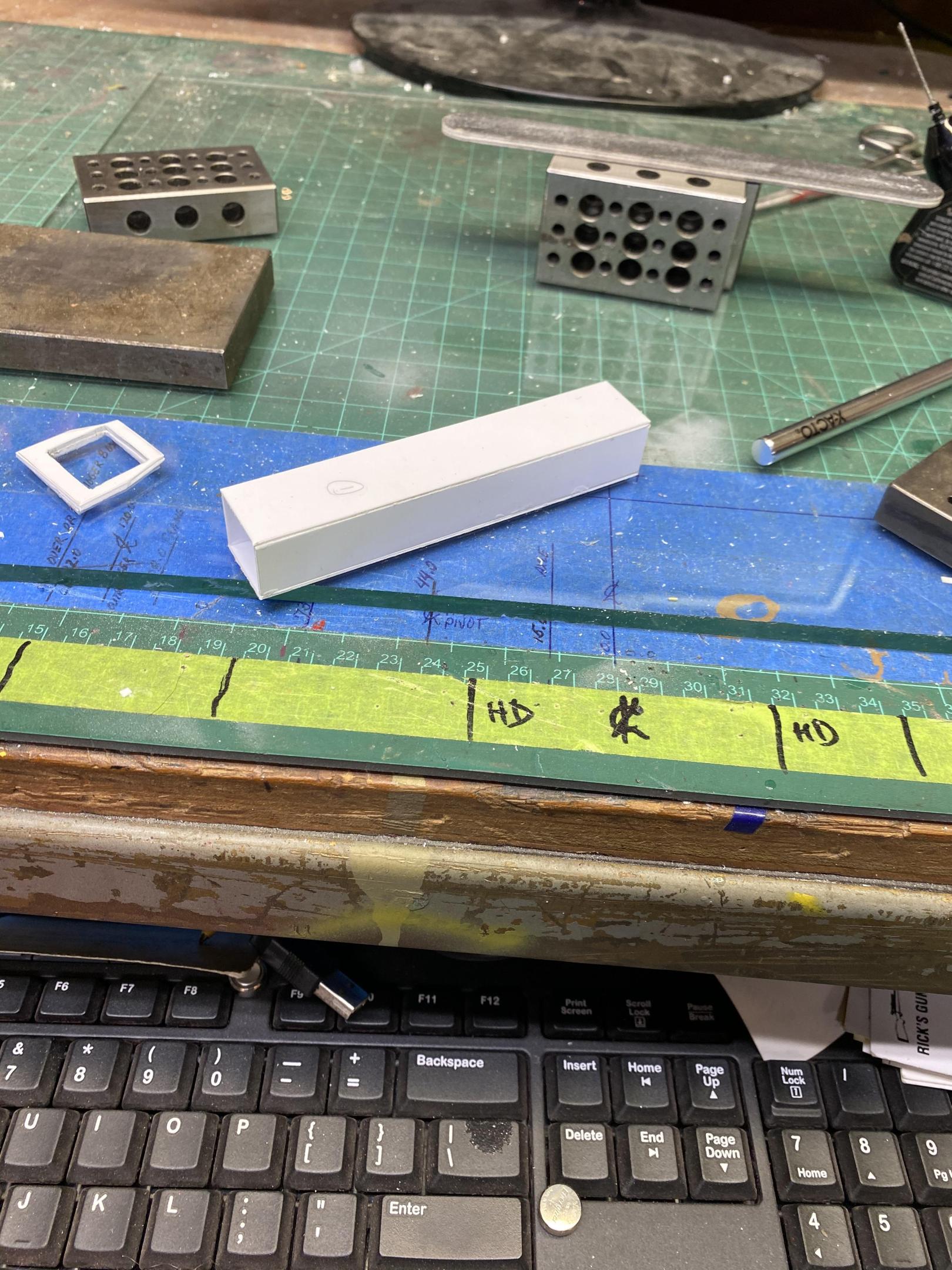

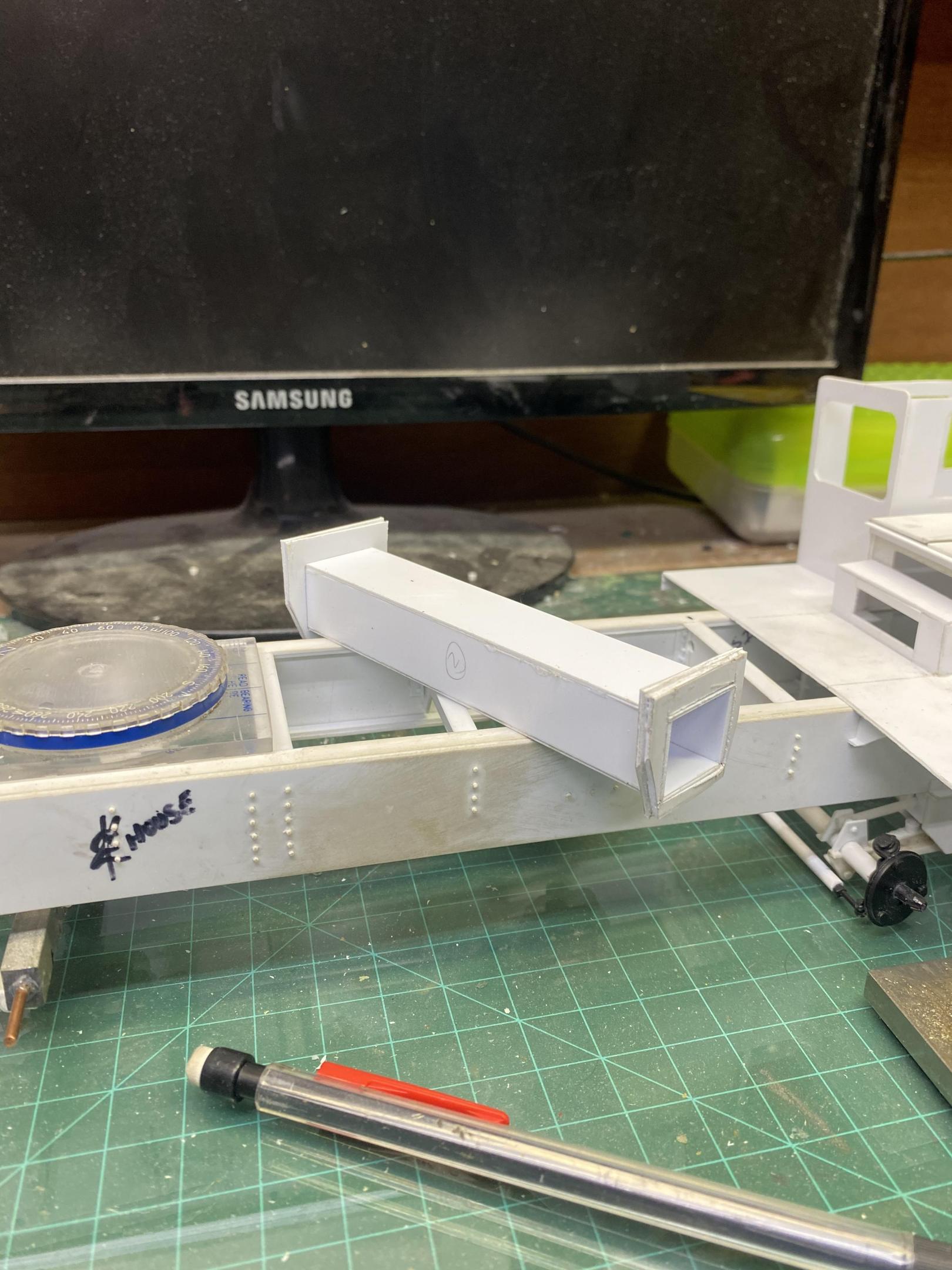

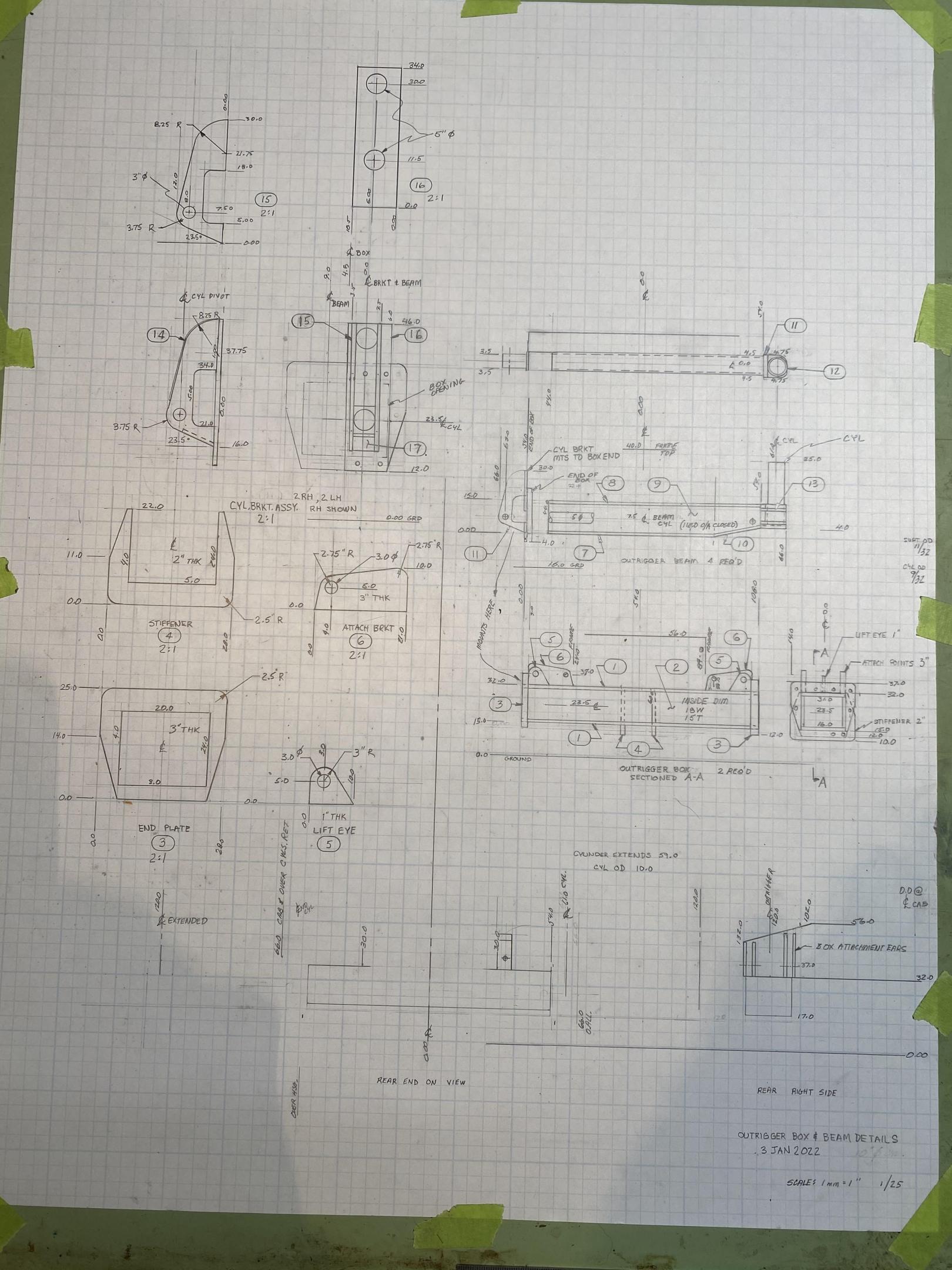

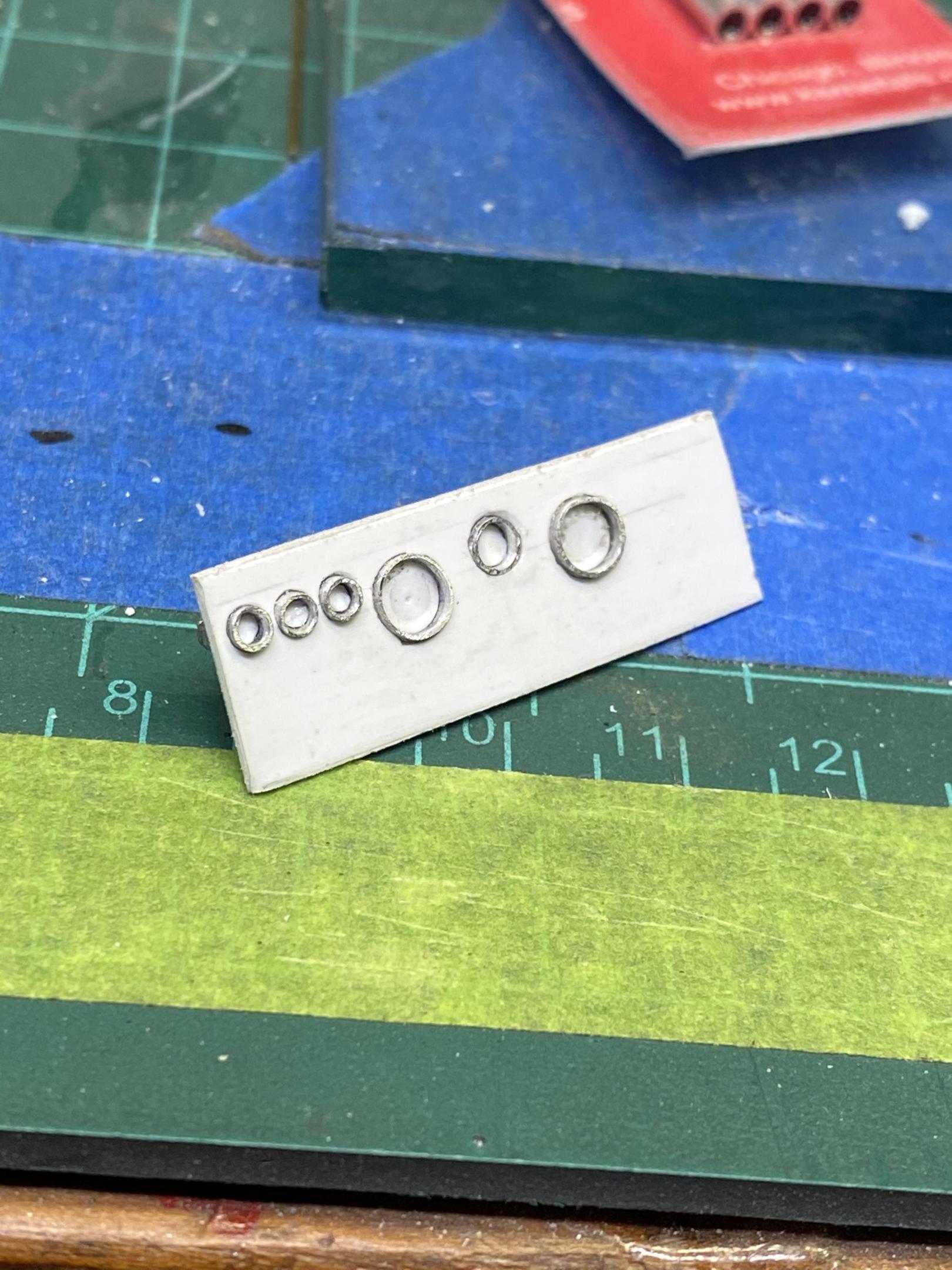

Just made up the rest of the beam box with the extension cylinder supports and the lift cylinder support housings on the ends of the extension beams. On to the extension cylinders and the attachment points on the carrier frame and the outrigger pads. Ended up being 84 parts so far per outrigger box/beam assembly without the extension cylinders which will add at least another 36 pieces per assembly. By the time the outriggers are totally done, they alone will total about 300+ pieces.

-

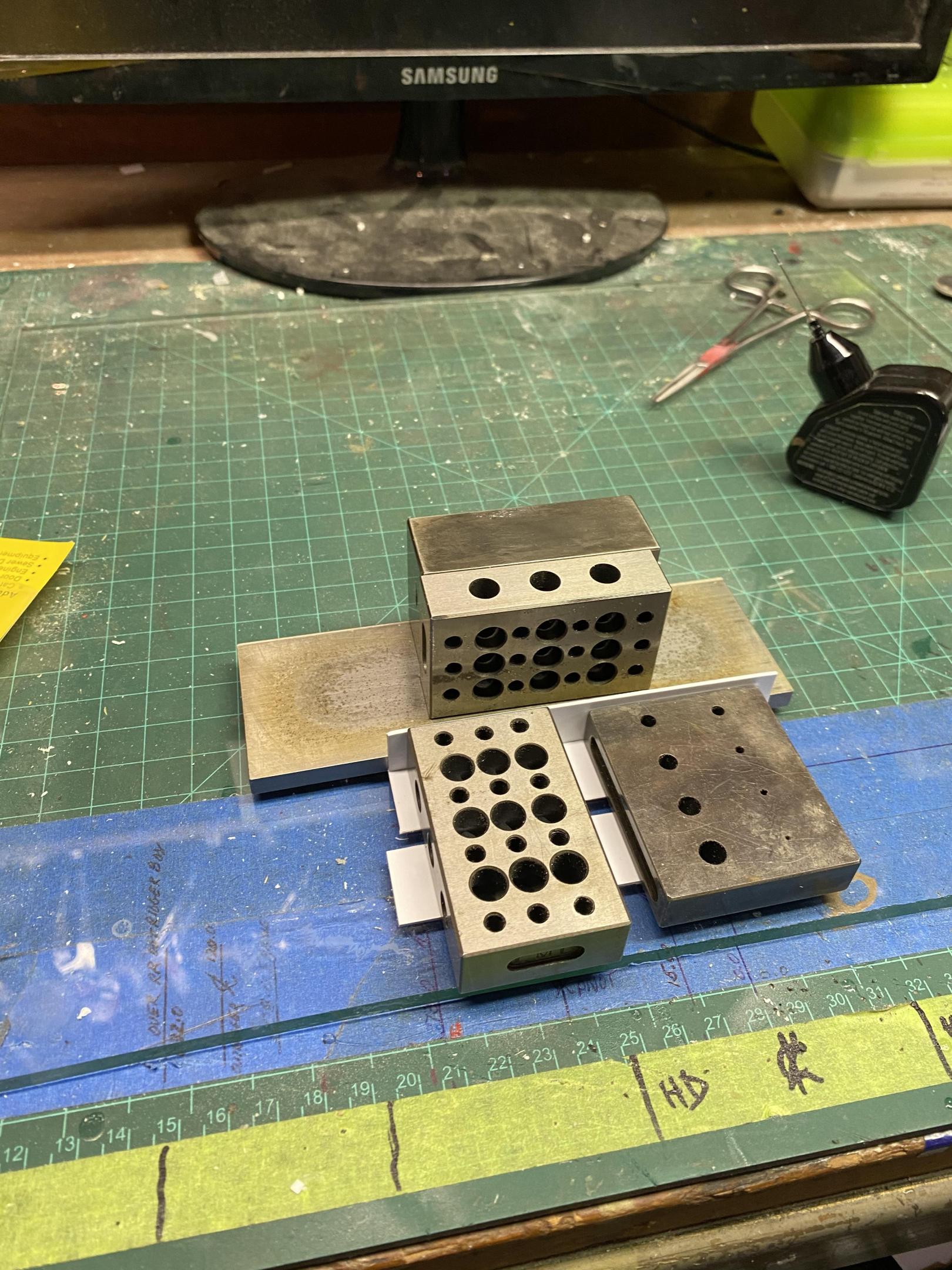

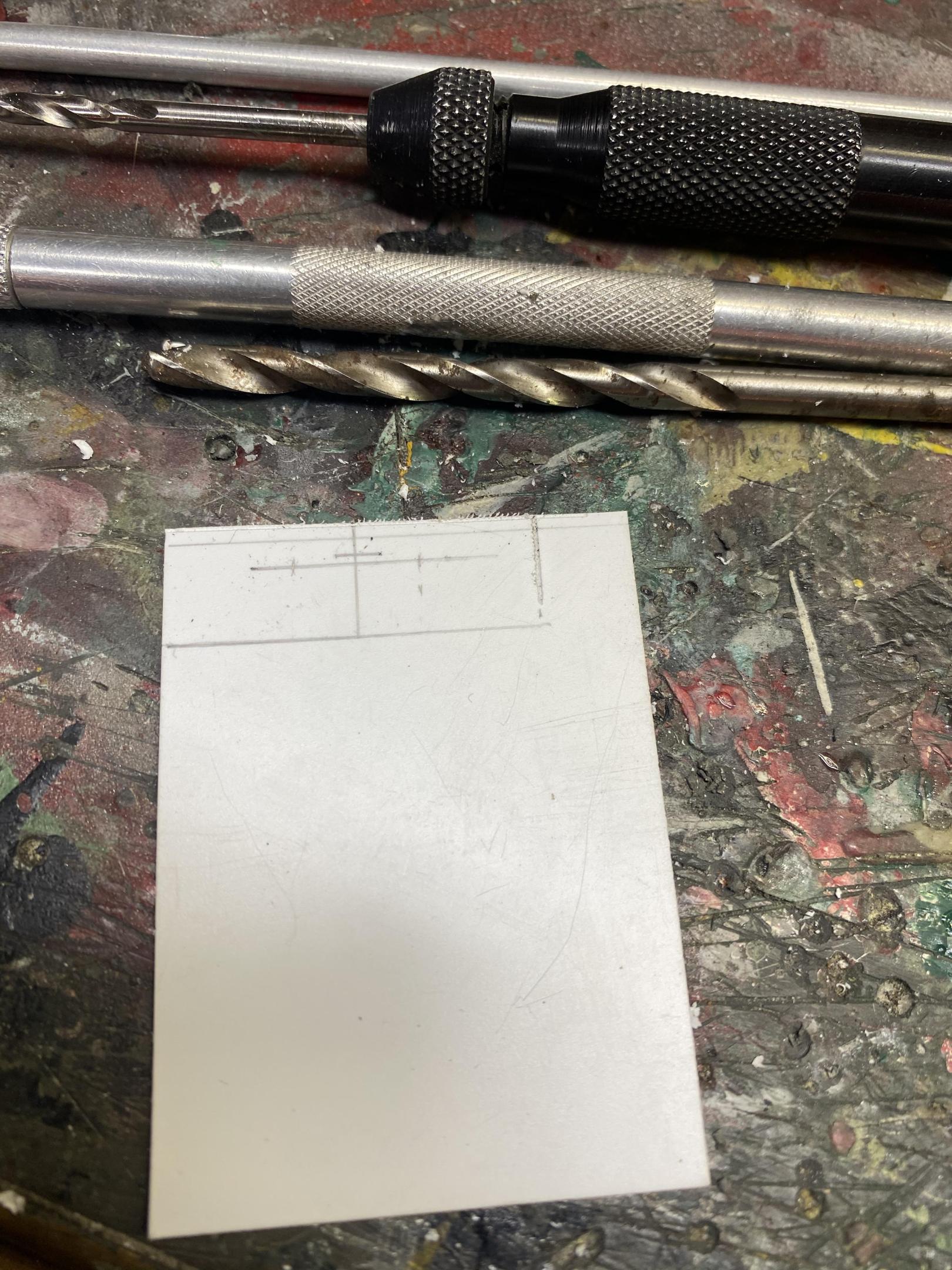

Many most likely have one already, but I just added these to my bench when I started the Link Belt HC-218 crane that is in the large trucks WIP section. Found these at an antique shop. One is a small size and the other is huge. These paper cutters are sharp, quick, and accurate and are easy to cut multiple quantities of the same size piece. I had a newly made one but it could hardly handle three sheets of paper. These old timers can cut 1/8” of plastic sheet without batting an eyeball! What a time saver!

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

The Official EBay Discussion Thread

redneckrigger replied to iamsuperdan's topic in General Automotive Talk (Trucks and Cars)

Back when the new Round 2 IHC CO-4070A was announced, I pre-ordered two of them from a seller on eBay that was selling them at a pretty good price. They were projected to be available in 1-2 months. In about a week and a half I received an envelope from them that included just a wooden business card. Nothing more. Was kind of wondering what was up with that, but life was extremely busy then, so I just sat back and waited. A month and a half went by, so I checked the status on the eBay page, and saw a tracking number. Hmmmm. Checked the tracking number and saw that it had shipped over a month before, and was marked as delivered. So I contacted the seller and asked what was up, and told him I didn't receive the trucks yet, but saw they were shipped, and early at that, and supposedly RECEIVED! WOW.................was like kicking over a hornet's nest. The guy was rude, vulgar, and used more four letter words than a drunken sailor, told me that I was blocked from his auctions, that I was not patient enough, and was trying to damage his business. I answered asking again what was going on, mentioned that I saw the tracking number, and saw it was delivered, and that I most certainly didn't get them. Got more four letter words and a claim that I did in fact get the kits. Then I checked the guy's feedback, and saw that he is a VERY rude guy, who apparently answers every buyer that has a question with vulgarity and rudeness and a block. So...............I contacted eBay and filed a "did not receive" claim. eBay in it's infinite wisdom, told me that I did indeed receive the package, as shown by the USPS tracking number. I contacted them at least five more times, explained what I DID receive, (the business card), and that I wanted my money back. We went round and around many times, and after sending them photos, and all else, and even showing them that the tracked package was a 4 ounce First Class package and could not possibly contain two truck kits, they FINALLY decided that the package was in fact stolen, and reluctantly refunded my money. STOLEN???? Total stupidity. And, due to the refund having been made for a "stolen" shipment, I could not post feedback for the sale showing other members what kind of seller this guy is. All I can figure out is that he uses the tracked package with the card to claim that the product was in fact delivered. And eBay bent over backwards to try to protect him, and in the end actually did. -

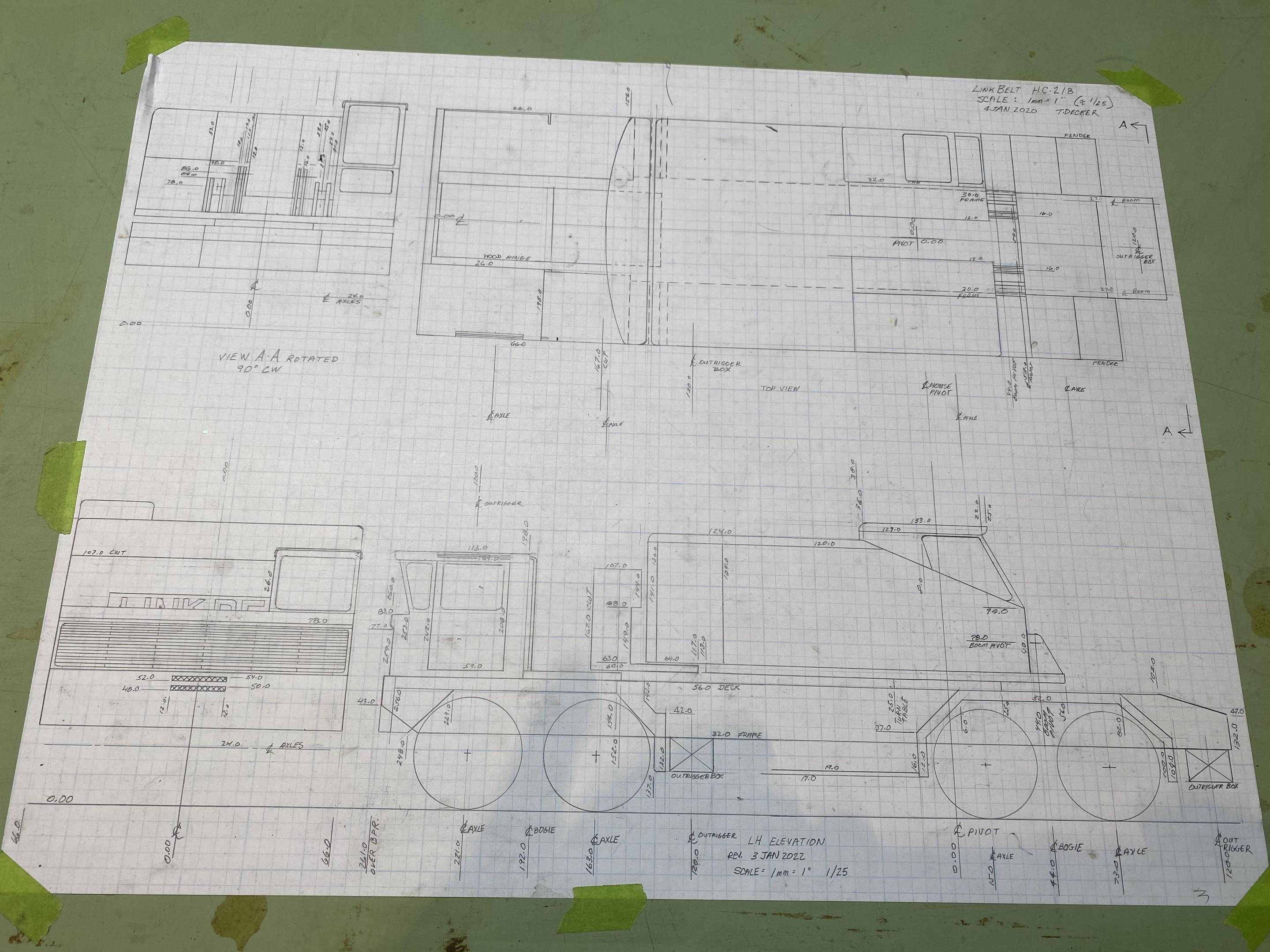

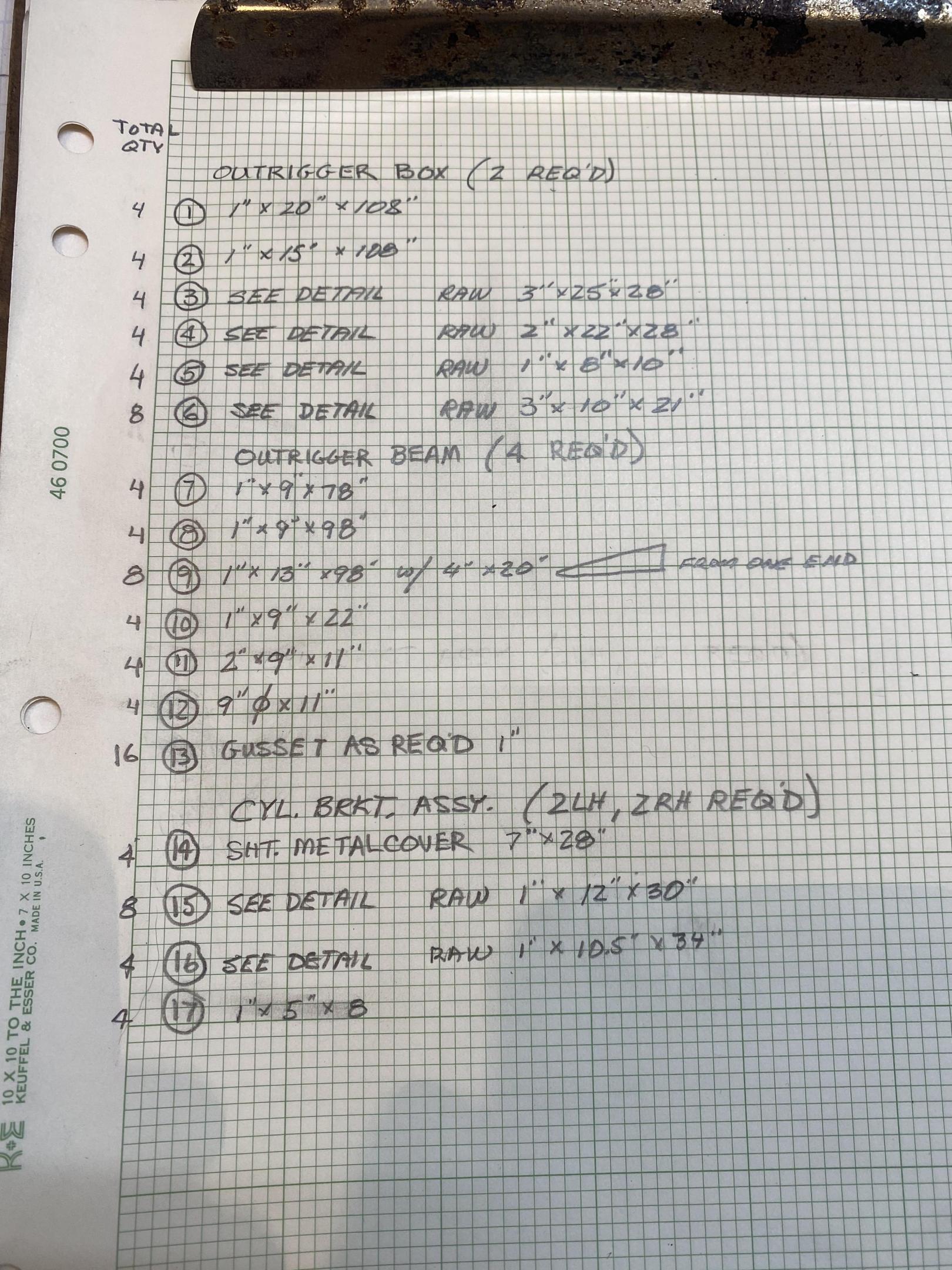

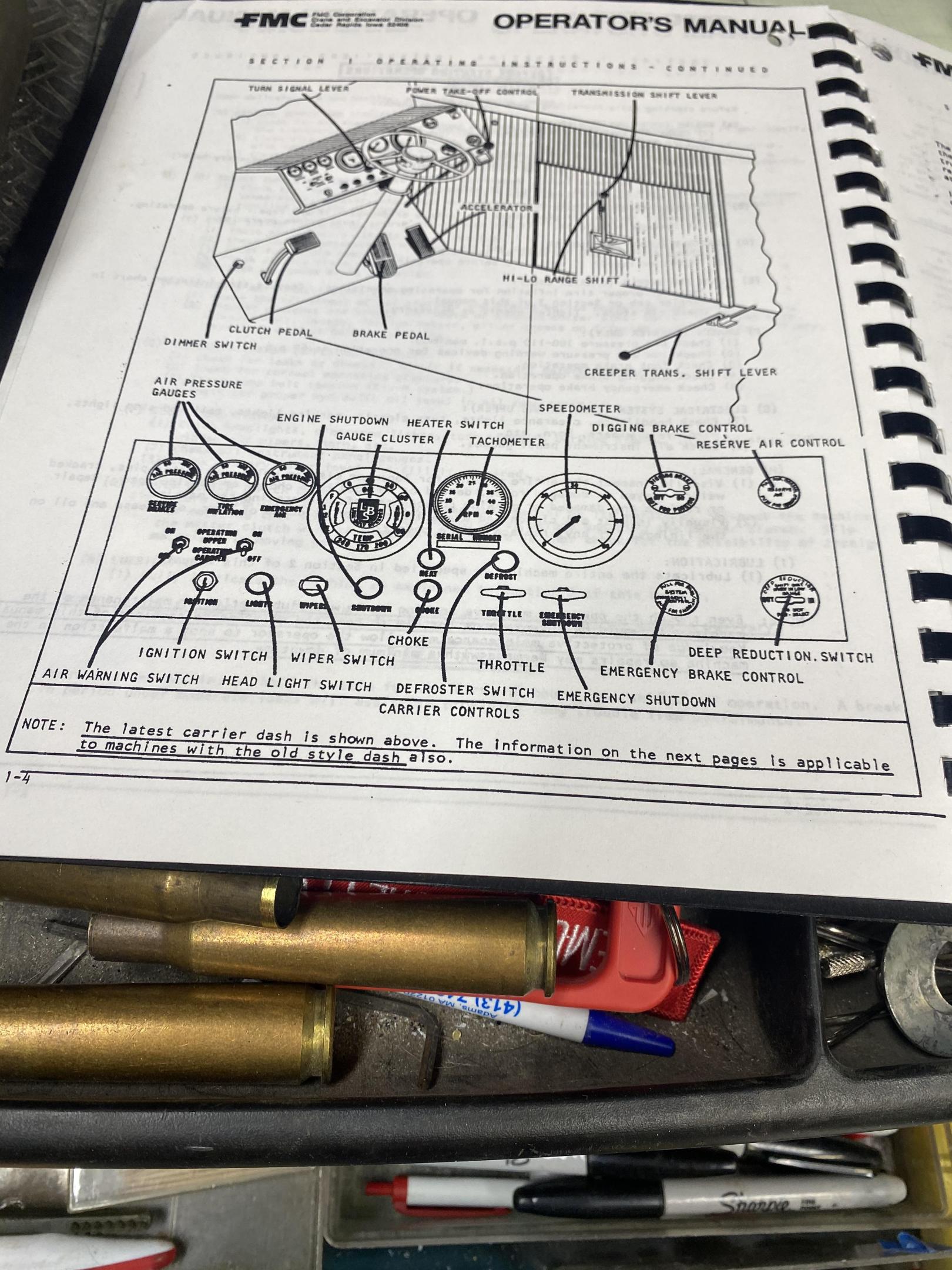

So I just finished the plans for the outrigger boxes, beams and cylinder brackets. The drawings are actually easy for me to do, as one of my many hats I wore in a former life was that of a mechanical engineer. Now it’s on to the fabrication! Seems like a pretty simple project, just lots of cutting and gluing, but the planning takes equally as long if not longer. Just the main outrigger boxes and beams, not counting cylinders etc, just the main structure consists of 92 pieces. The research for these projects I do consists of obtaining operators, parts and shop manuals for the machine in question. Then I find photos online and if possible take some myself if the machine is accessible. If I can access the machine I also take some basic measurements. The vast majority of the dimensions in my drawings are obtained by extrapolation from manuals, and photos. Then, I evaluate what the drawings look like as far as scale. Having worked with all of what I build, it is easy to use the calibrated eyeball to check for accuracy! And that is why it takes so long to build these!

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Anyone deal with Motor City Resin Casters?

redneckrigger replied to gbtr6's topic in Car Aftermarket / Resin / 3D Printed

Sadly, this is why so many cottage industry casters close up shop. They make a great product, all the while working a fulltime job, (or two), to make a living, and doing the casting on the side. And then when they get tons of orders, and lead times go past what the buyer thinks reasonable, without knowing a THING about the sellers' life, business, health, time demands due to jobs etc., that buyer jumps on them all over social media. Eventually, that seller decides the heck with it. And THEN those that caused their demise, bemoan the fact that the seller went out of business and those great products are no longer available. Yeah, a note on the website saying what is going on, or simply a note that there will be NO lead times given and you will get your order when it is done, period, would go a long way towards letting people know they have to wait, (IF those people take the time to even read and comprehend the note). However, often the time needed to keep buyers informed takes time away from other more pressing issues, and simply does not get done. When you are dealing with an established, reputable, quality seller, like Jeff, there is little to NO reason to expect that he is going to screw you, or anyone else for that matter. All I can say is I have some of Motor City's resins and they are fantastic. And I have no issue waiting for however long it takes. Patience is a virtue that many people need to learn how to practice. Thank you, Jeff, for continuing to offer such quality merchandise, even in the face of interference from life, and impatient buyers. -

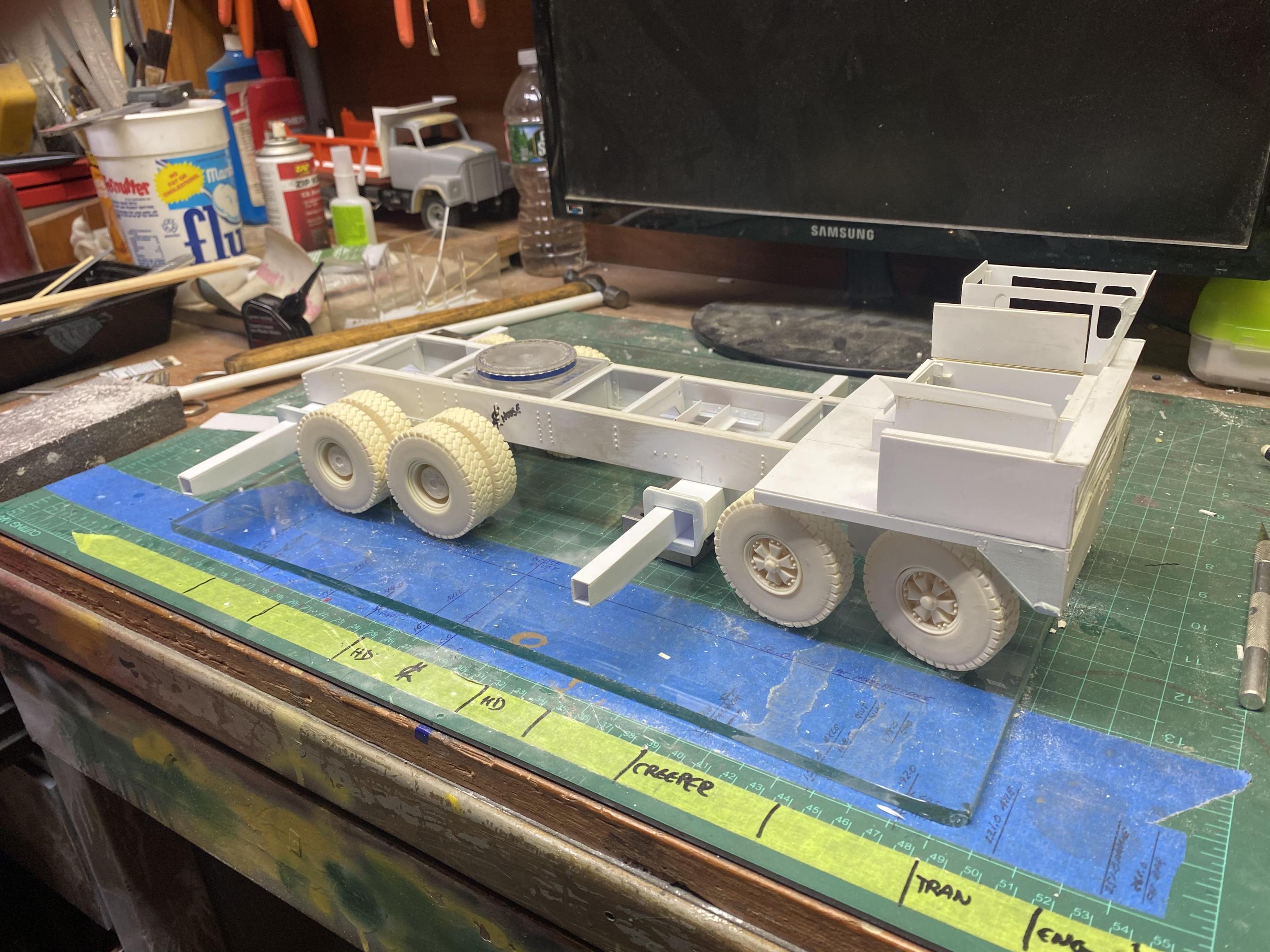

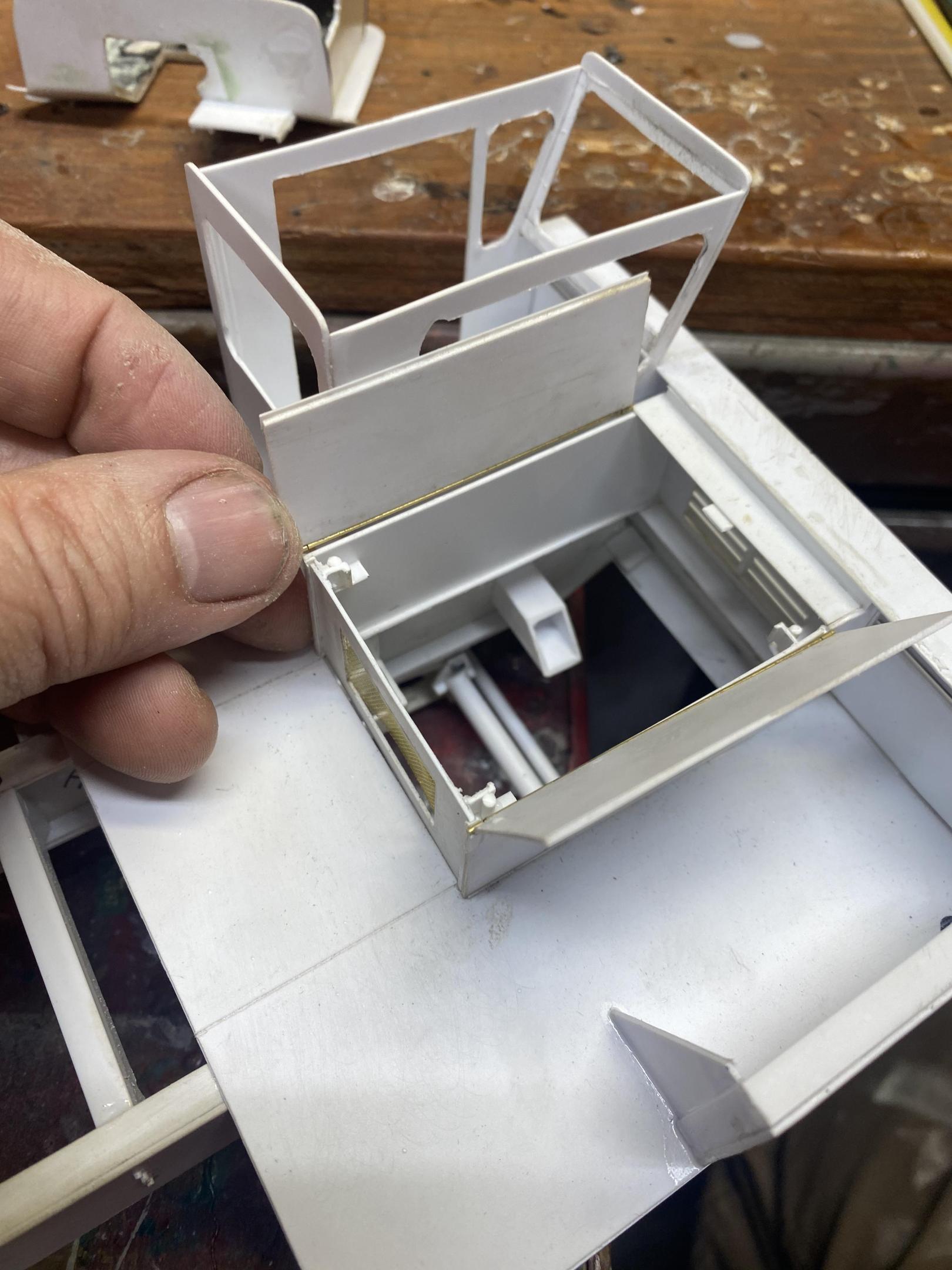

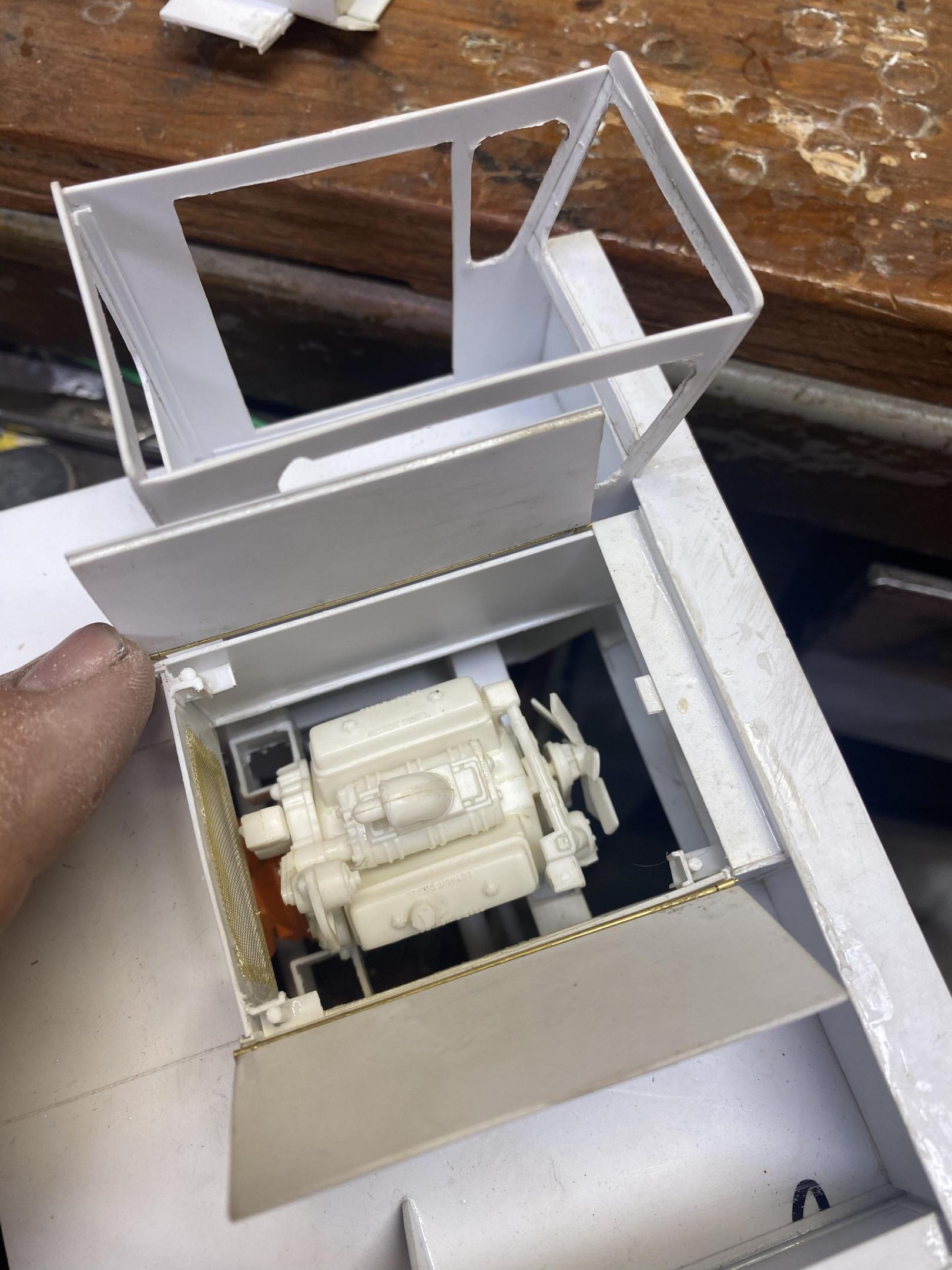

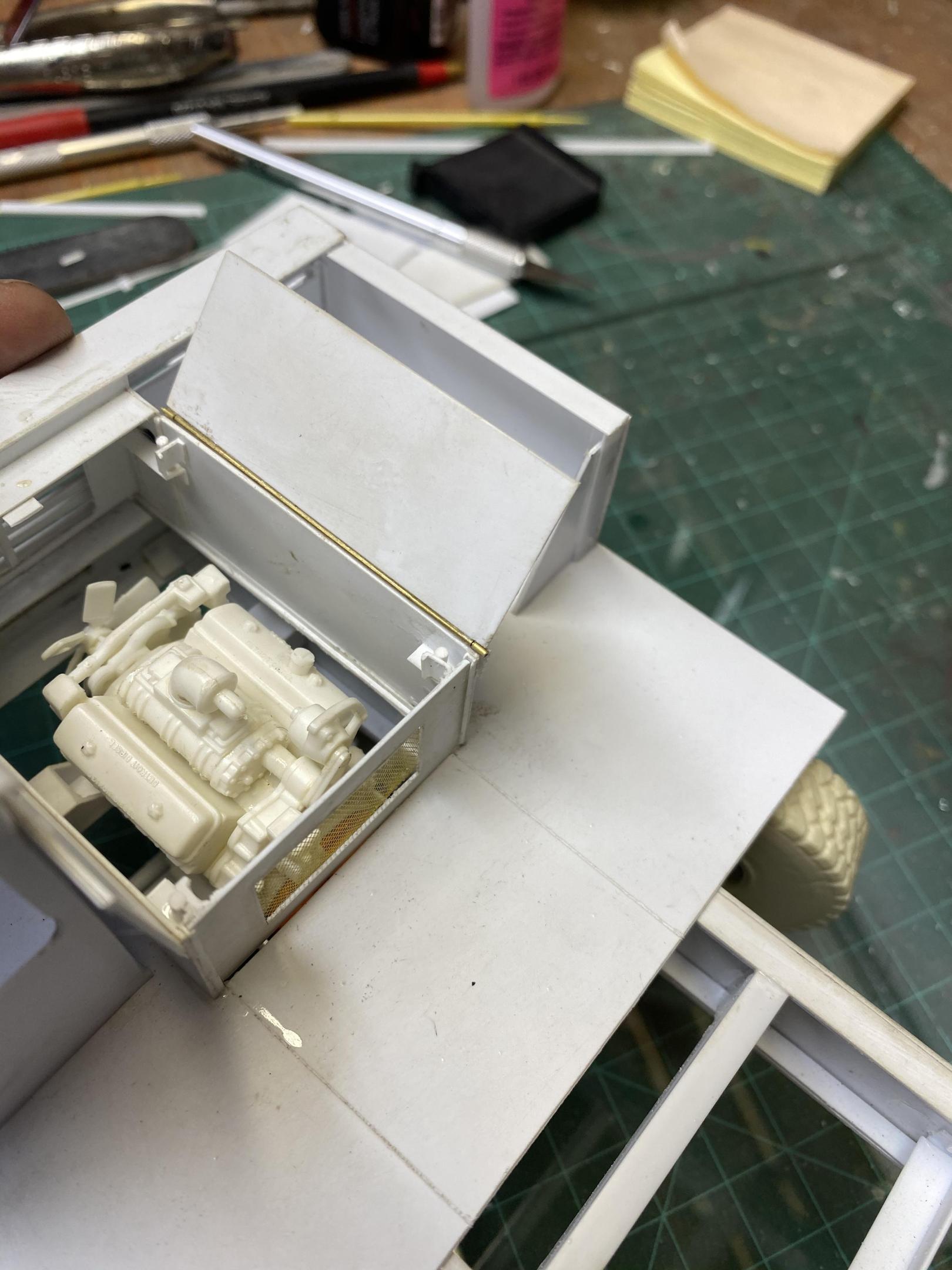

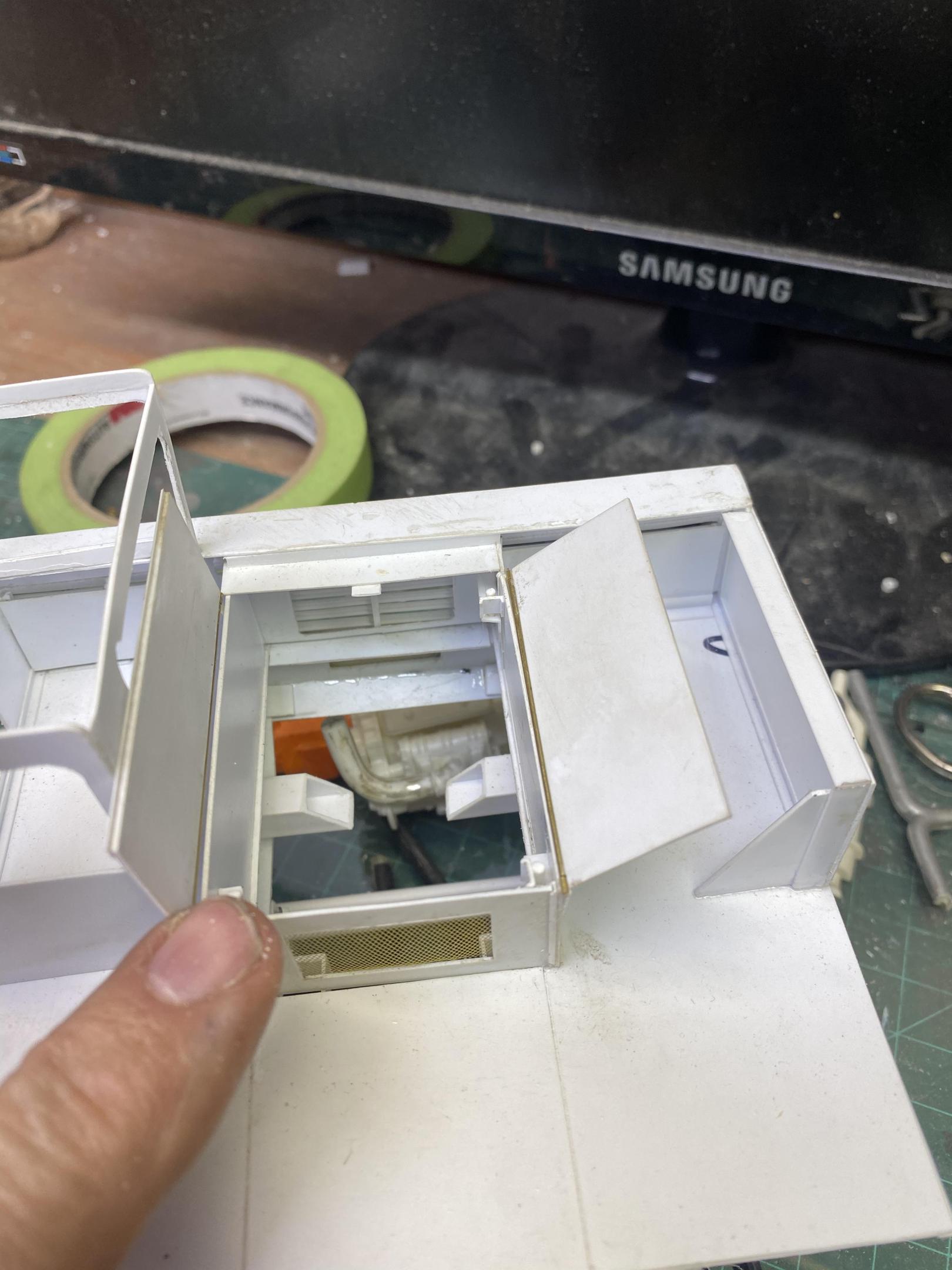

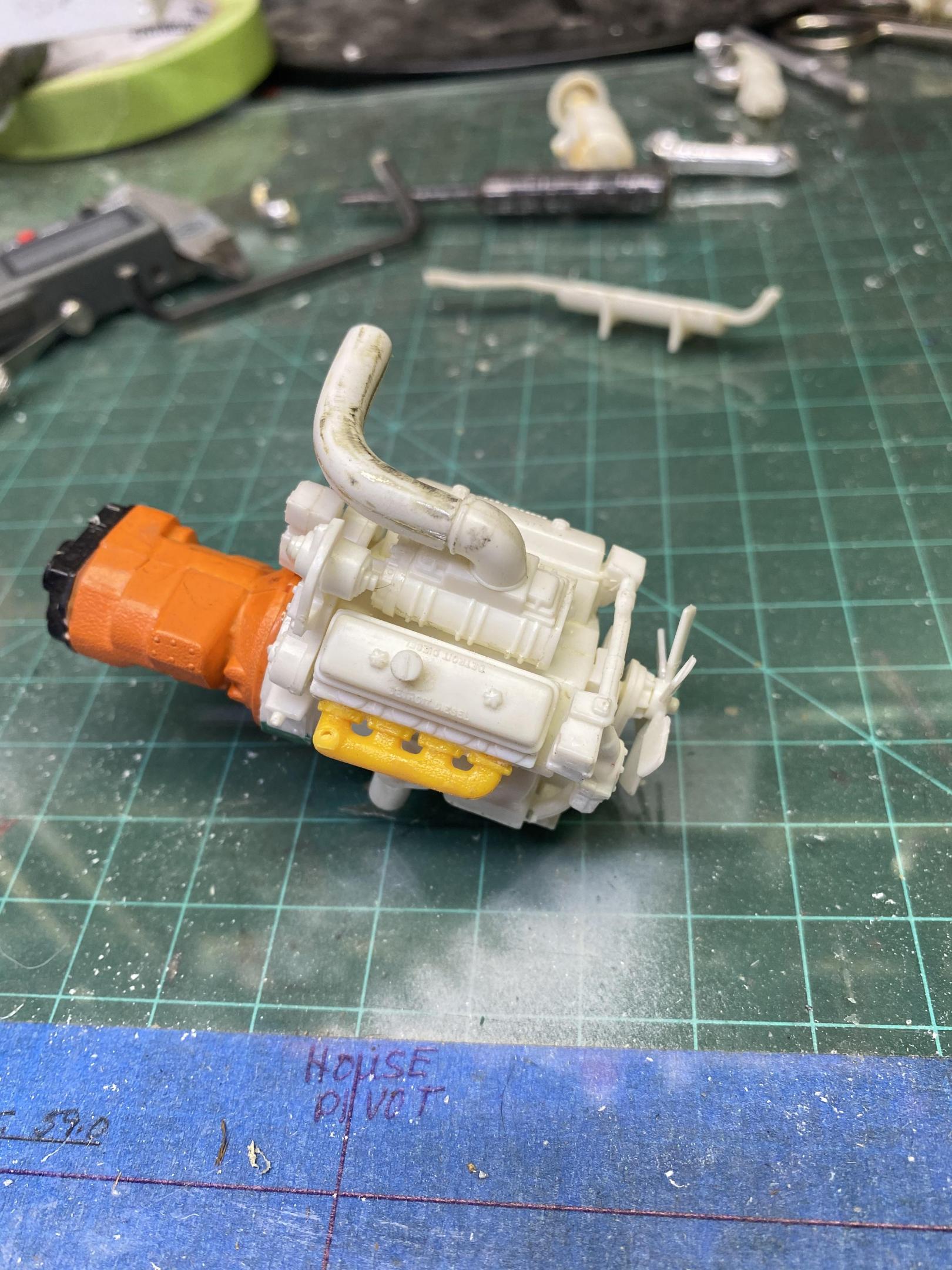

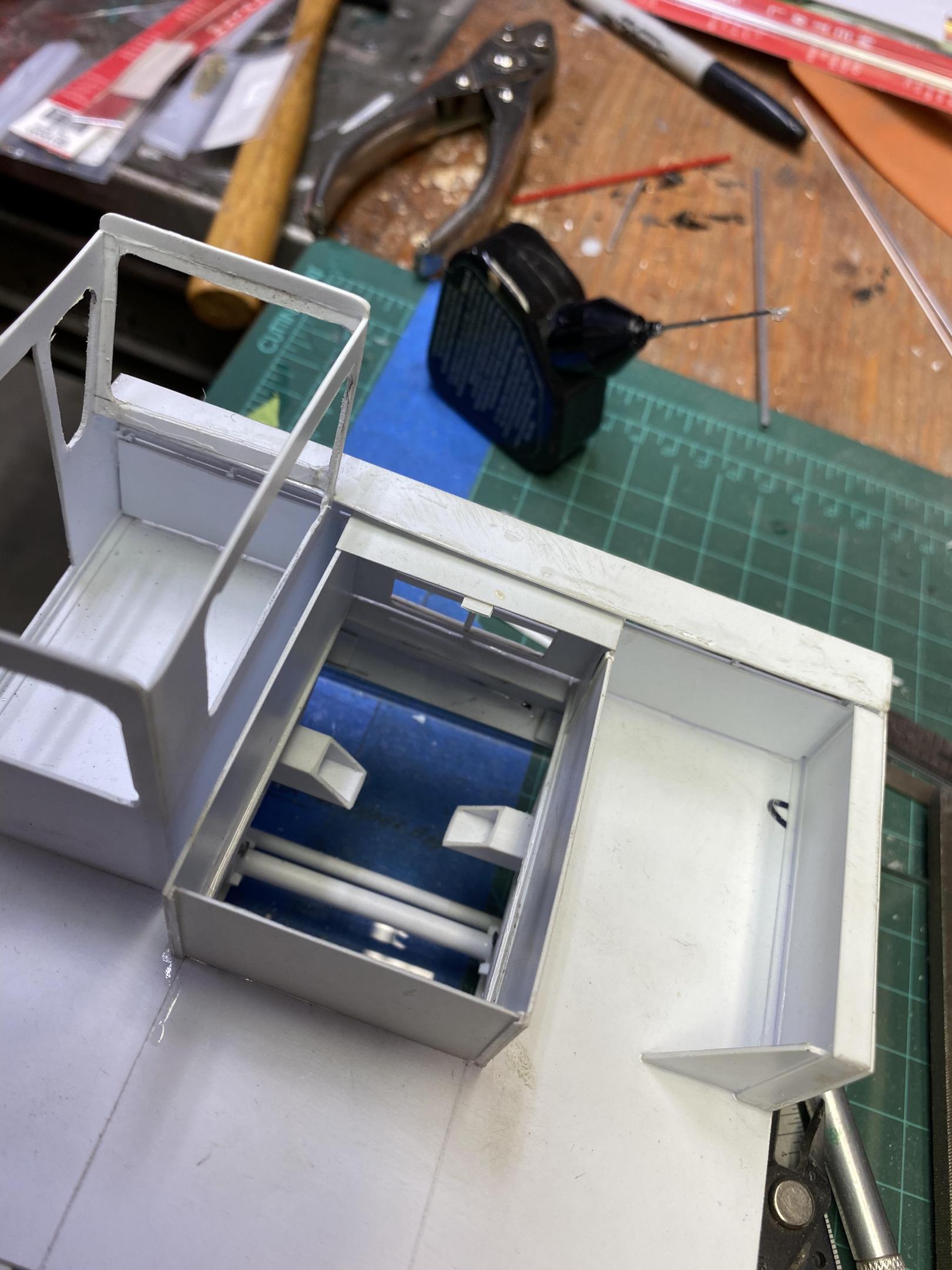

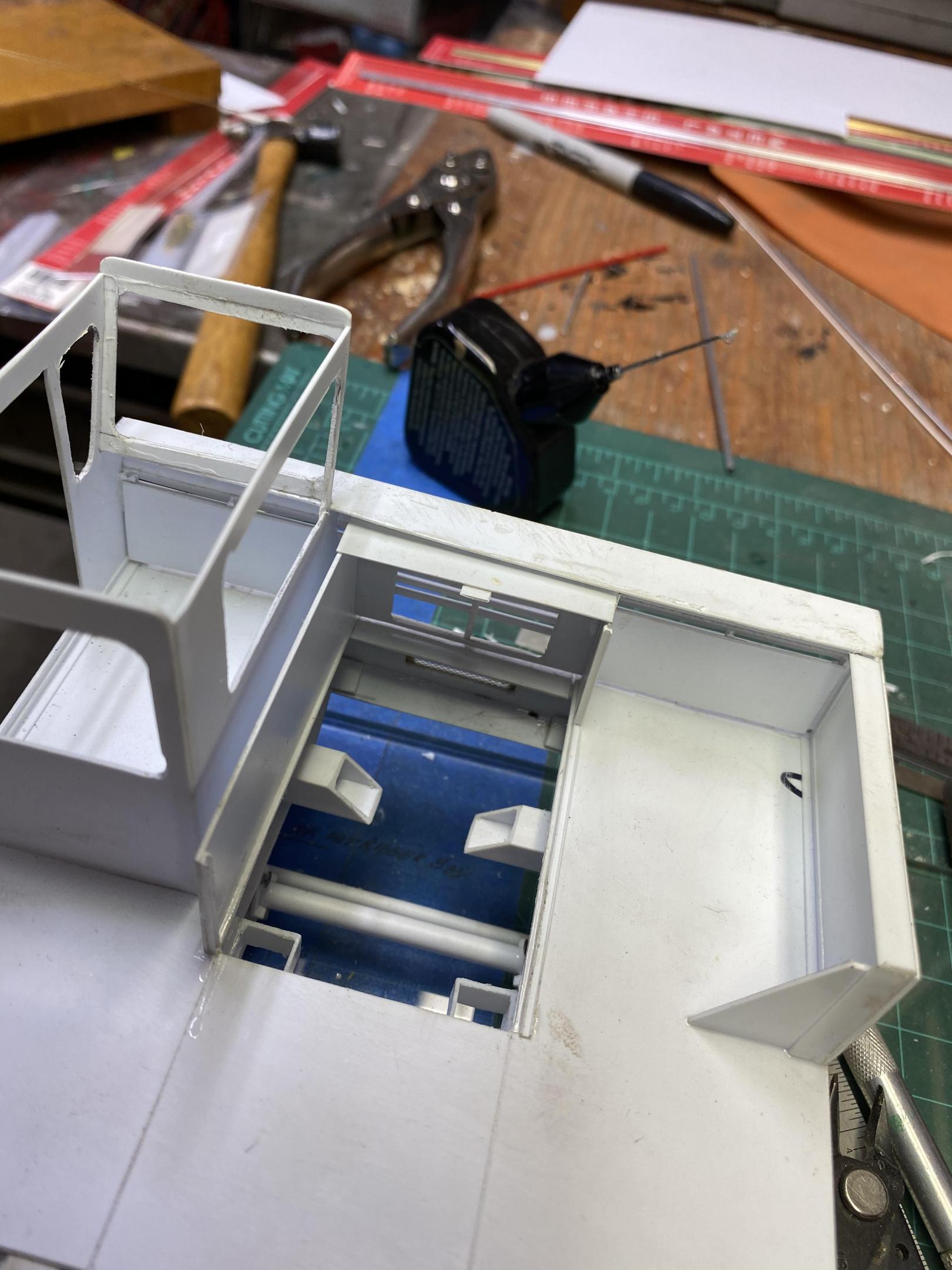

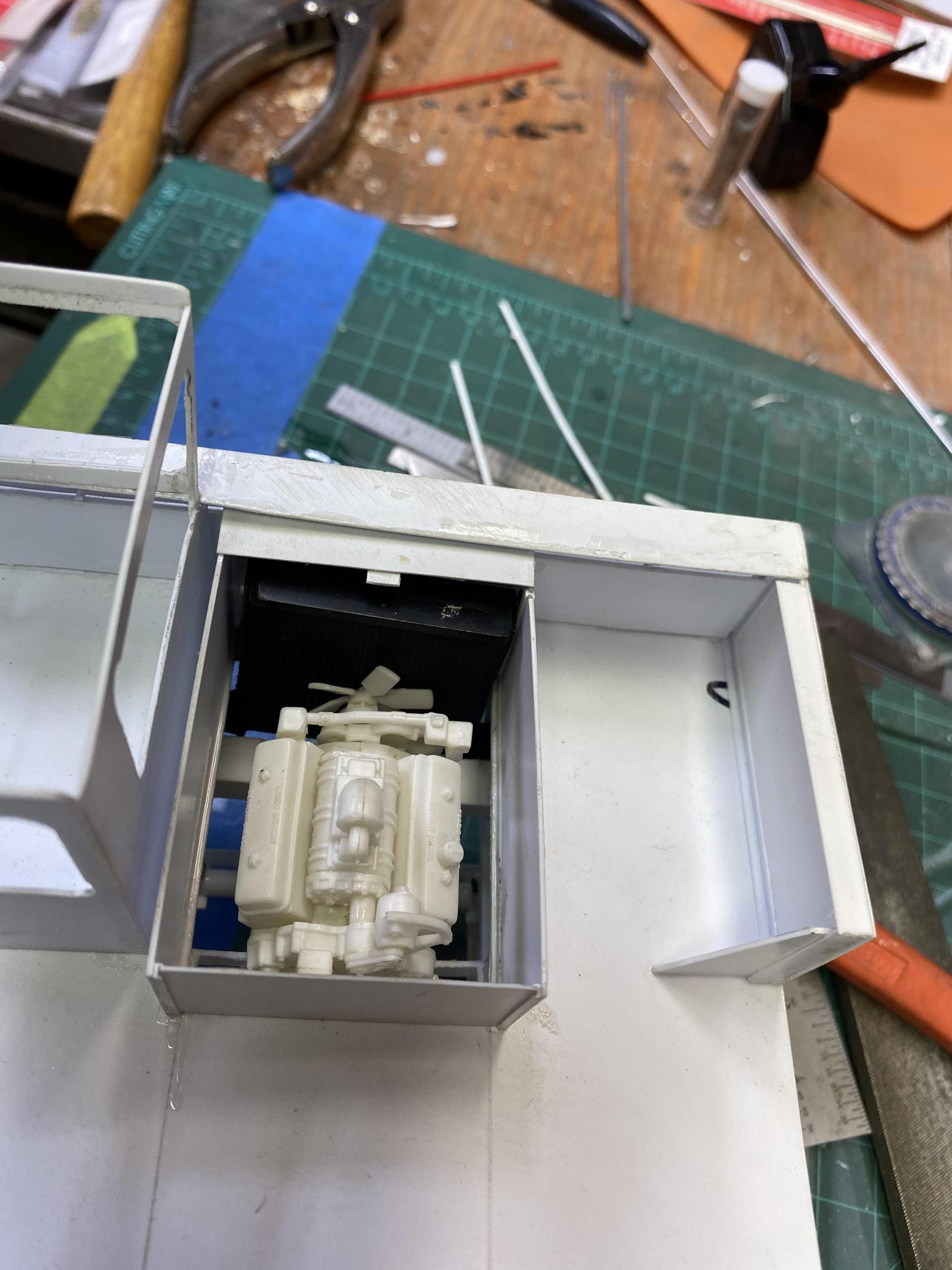

With my shop being twice as busy as last year, which was twice as busy as the year before, I have been hard pressed to find time at the bench, or the energy! But, deer season is over, and coupled with winter being here so it means more time inside, I feel great having gotten back to this build. So, got the engine enclosure done, with the covers hinged and a rear grille installed. Also made up the air cleaner and the muffler, which will get a heat guard soon. Also found the correct upswept exhaust manifolds for the 8V71 and fitted the intake tubing. Am drafting the drawings for the outrigger assemblies at this time. And started on the driver’s instrument panel. Unimaginable amount of work left, but it feels wonderful to be back at it!

-

Got married in 1975, went to Cape Cod in Massachusetts for our honeymoon. Went out to Martha's Vineyard on the ferry and when we drove off the ferry, we stopped at a variety store for a snack. Found about 25 1968 and 1969 AMT and MPC annual kits on the shelf. Bought them all and stuffed them into my 69 Mustang fastback and spent the rest of the two weeks riding around like a toy store on wheels! Another time shortly thereafter in 1976, I stopped at a Chevy dealer in Pittsfield, MA after work, to ask if they had any promos available. The salesman brought me into the cellar where there was a stash of promos from 1968 to 1970. I asked him what they wanted for all of them. He asked if $2 each was too much. Good thing it was pay day, as I dropped $110 right on the spot. Wish I had some of either batch of the kits or promos still!

-

Well done Dave and your team, keep up the good work. This forum continues to be the best in the hobby!

-

Thanks all for the great comments. Unfortunately, I am in the middle of unprecedented business at my gun shop, which leaves me with about negative 3 energy and time/drive/desire to do any building. Also just had a great friend pass and we bought his 500 gun collection, which has consumed our whole staff for the last two months. So...................have tried to get some work done, but am spinning my wheels. BUT.............I AM enjoying watching all of the great work being done by all of my friends on this forum. Hopefully, one day soon, will get back to the bench...............and STAY there1

-

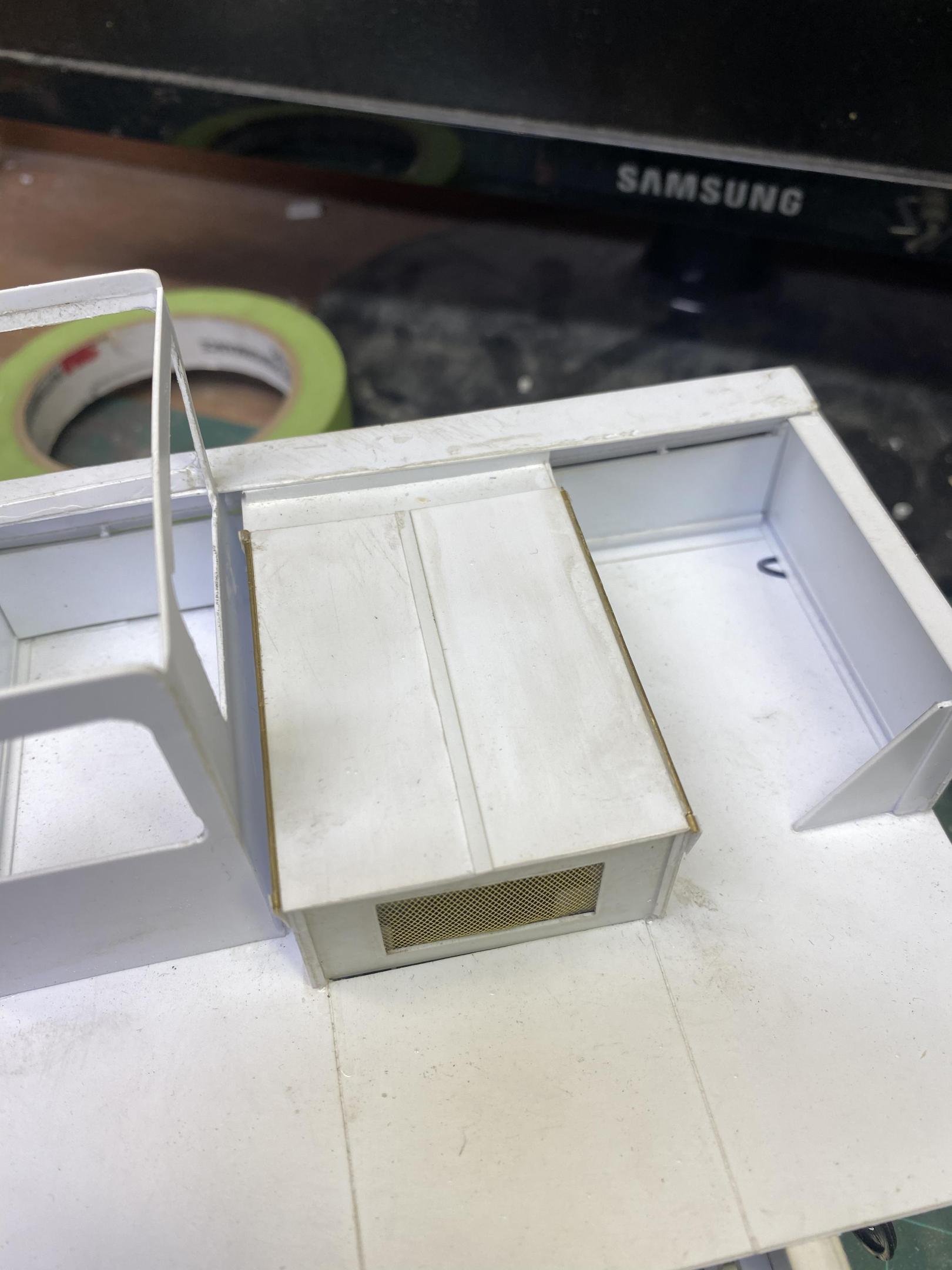

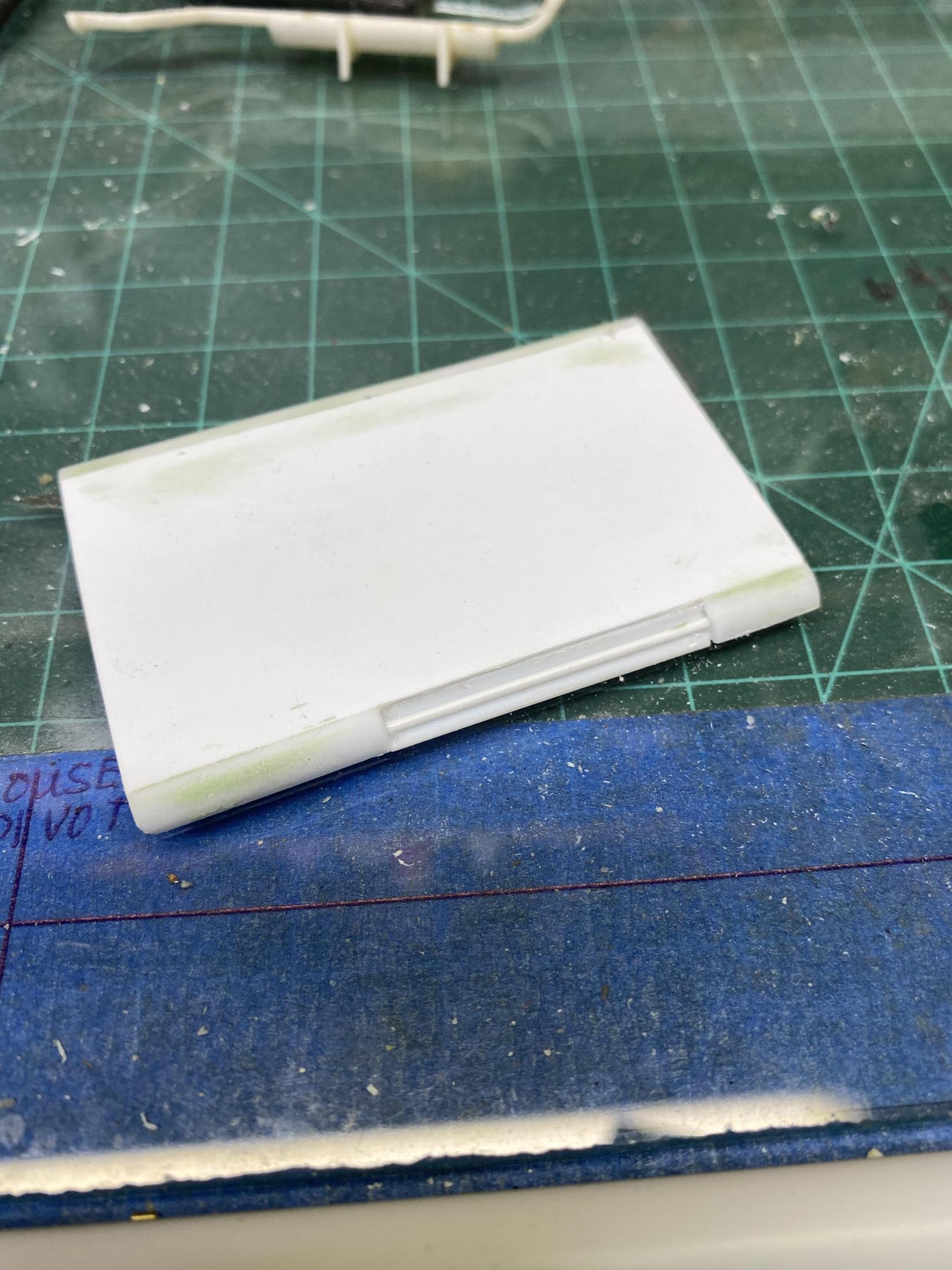

Finally found a few minutes to get to the bench and work on this project that has been stalled for way too long. My shop is going crazy, teaching a couple nights each week, and life in general have conspired along with a case of builders block to bring this to a screeching halt. But, MAYBE, this kick start will get it going again. Anyways, just a little, but straightened the grille, and made the engine enclosure up for the carrier. Now working on the hinges. This was always going to be a huge involved time consuming build. Hoping that at least now I can keep it going!

-

Using Firefox on Windows 10, no problem at all......................though it IS understandable why ads are necessary. Having this forum with advertising, is far better than no advertising..........................and no forum!