-

Posts

250 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by OldNYJim

-

Revell 29 closed cab pickup

OldNYJim replied to Bullybeef's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

That’s my vote…always ? This is gonna be good! -

I wish Aldi sold kits here - would make getting groceries less tedious ? Great start - love that low-low stance!

- 766 replies

-

- 1

-

-

- stalled builds

- quick builds

-

(and 2 more)

Tagged with:

-

Hot Rod Hauler

OldNYJim replied to Tarkmucker's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Ohh, cool project Mark! I had something VERY similar in mind myself, but didn’t get to it yet. Great start!! -

I kept going back every week to pick up a 55 Chevy and a 37 Ford and they just never had any stock…in the end I relented and got smart and ordered them on Amazon. It was a few bucks more, but I already spent a few bucks more in gas hunting them down anyway. I too would like to see fuller shelves and more of the new stuff, but I’m sure their management know what they’re doing (or are under that impression)

-

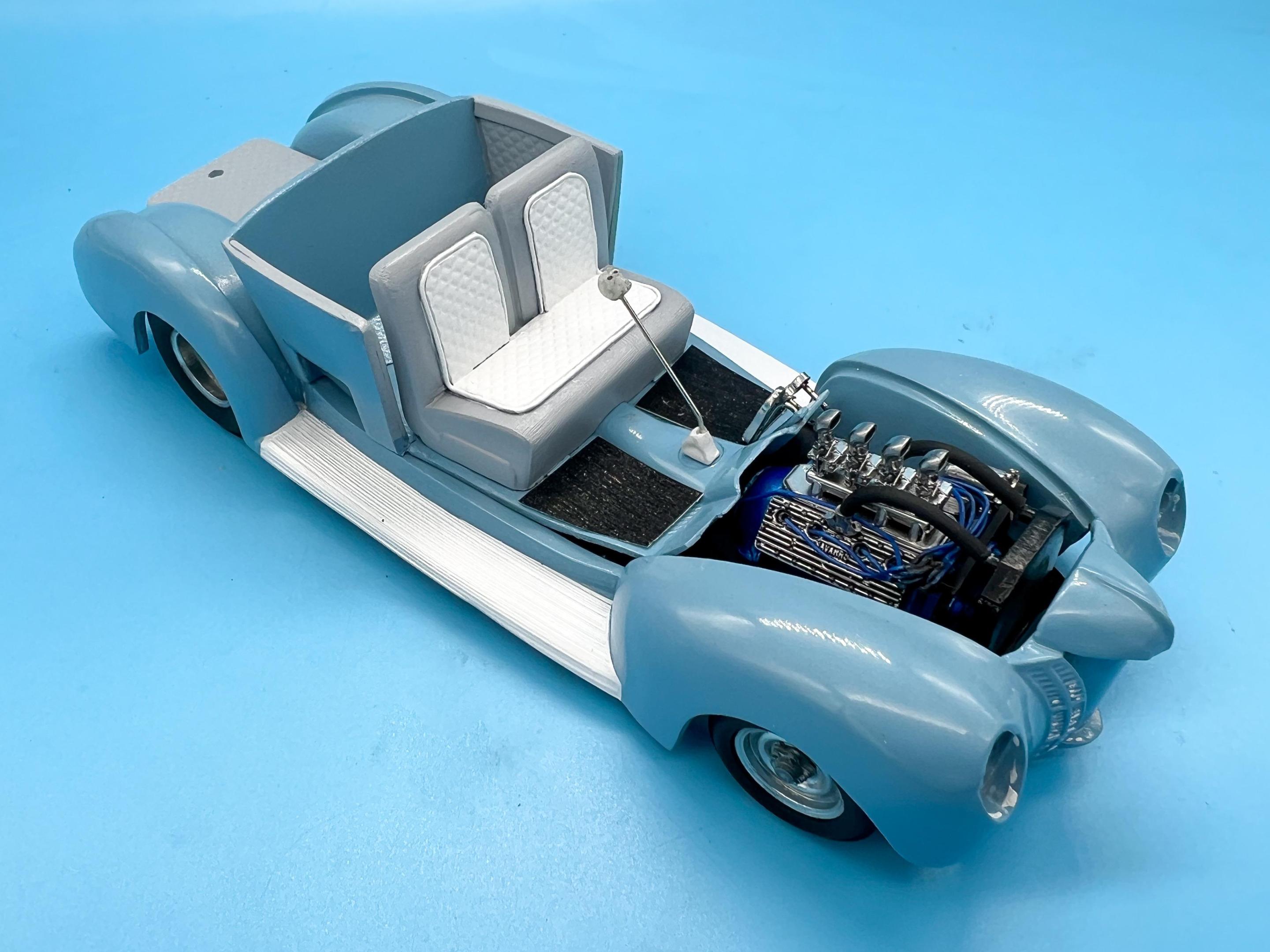

Thanks for all the nice comments everyone! Some more progress this weekend… Polished out the body: I wasn’t quite done when I took this pic, but my favorite reflection test came out ok… Then masked and shot white on the rubber foot steps (whatever those are called…) With that done, I got the frame under there, mostly finished up the engine and got the wheels mounted: Next up, got the interior together. I could’ve gone more complex and detailed on the interior but I’ll be happy if everything just fits together still when I’m done… Another test to make sure everything still works - man, I love these door-open shots… Next up get the grill, and front and rear bumpers installed plus the headlamps: And with that we’re starting to get down to the little stuff…headlamp lenses (found that Revell 32 ones fit like a glove), taillights, radiator cap, fuel filler tube and cap, door and trunk handles…bunch of little stuff, but it’s coming together! More soon, soon as I’ve done more!

-

Like a couple of others have said already - outstanding CRAFTSMANSHIP. Really beautiful work

-

There’s a great thread here (with advise from sources I consider trustworthy) - I’m not sure how much of this crosses over to the Model A tho…

-

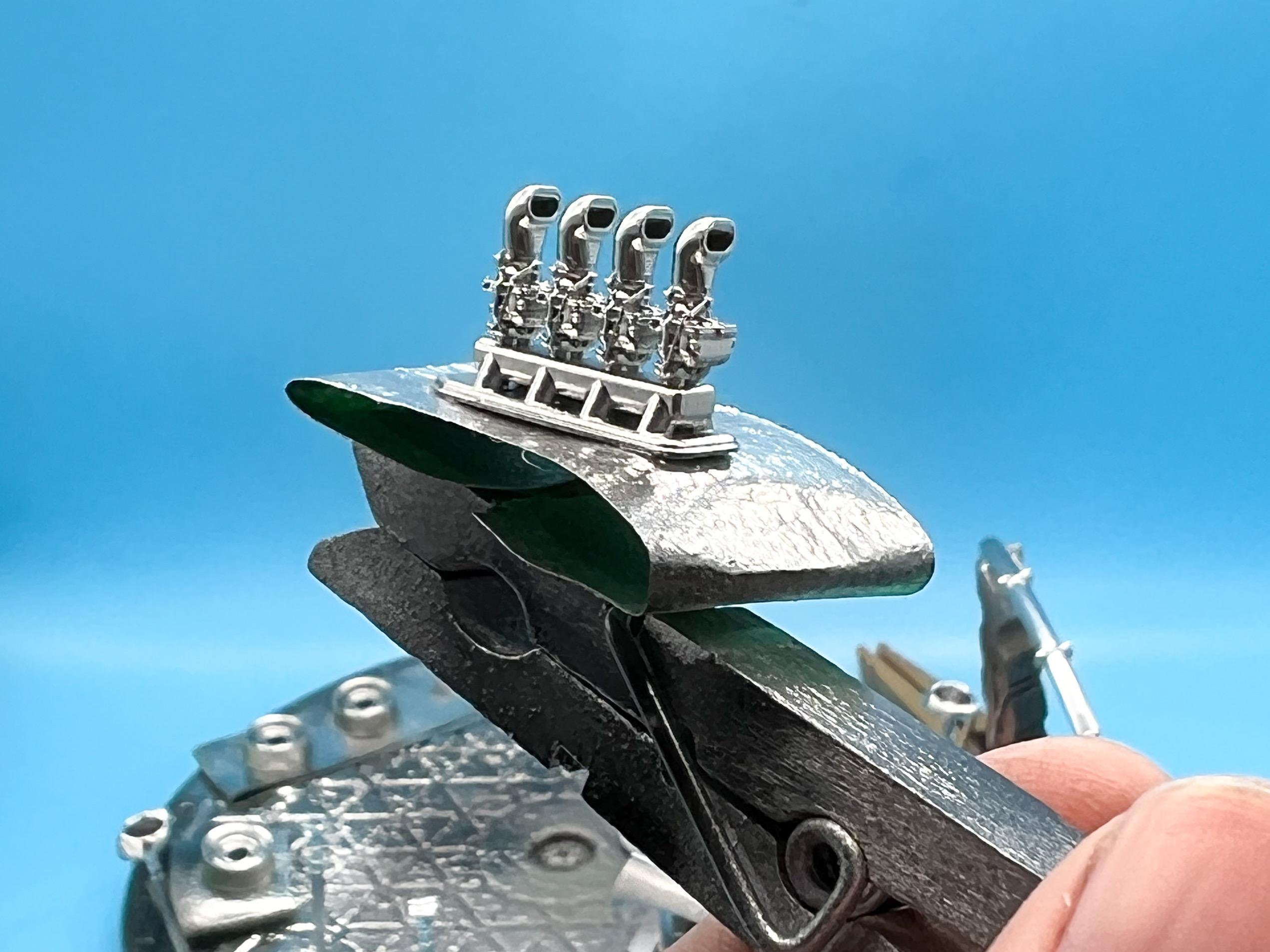

Thanks everyone!! Appreciate all the kind comments! I’ve been prepping and painting a bunch of stuff the last few days… Shot the engine in my favorite blue: Then shot the interior tub - went with a darkened version of the body color with a nice light gray rather than just a straight white…I’m hoping some little highlights in chrome and white will draw your eye to some of the interesting details and not have the bigger parts like the seat swallow them up… Prepped a bunch of parts for chrome - started with straight up black enamel, then polished out the bigger parts as best I could: Then chrome: Check out how the detail on those carbs pops now they’re all shiny! ? And then I gave some of the mechanical bits a wash with a new acrylic medium I picked up recently: Helps pick out that detail even more!!! It still blows my mind that a little shoebox sized machine can make these perfect little model parts on command… I’ve been shooting clear on the body - shot the last coat this evening and will polish it out this weekend most likely: And that’s about as far as I’ve got this week so far…LOTS to do still, and nothing really FINISHED but I’m almost done with the painting stage - which means I’m close to the detailing and assembly stage (which is my favorite and least-favorite, combined) Thanks for looking! More soon!

-

Battery replacement cost…..

OldNYJim replied to BlackSheep214's topic in General Automotive Talk (Trucks and Cars)

This exact issue happened to my brother in law on Christmas eve too! We had 19 degree weather here in NW Indiana on Christmas eve, and his Tesla just wouldn't charge. Supercharger wouldn't charge it, took it to a relative's garage and put the heat on for a few hours...still wouldn't charge...he ended up trapped in a motel over Christmas because he was saving his 30-miles remaining range until it was warm enough to get back to the nearest Supercharger to try again. BUT, in the same weather it was so cold that I couldn't get my dinosaur-fuelled Mustang into gear when I first started it, and the idle was lumpy as a pile of rocks for 10 minutes until it finally started to warm up a little, and then it developed a sensor issue on my commute that put it into limp mode that eventually away when the weather was a little warmer. Only solution I've figured out is just move where it isn't so cold ?♂️? -

Absolutely agree. But for all the talk of these old Revell tools not being to 'today's standards', a lot of the parts in these older kits FAR exceed the level of detail in modern kits. For example, compare the detail on the Small Block Chevy that you can find in the Atlantis Mooneyes kit to the Small Block in the latest Revell Model A kits and it makes the new parts look blocky and toy-like by comparison. And the reissued suspension and frame parts kits are a goldmine of beautifully-tooled vintage hot rod parts. That Caddy tho, yeah, it's the old Revell kit with the multi-piece body...I've got one here to build and I'm excited to tackle it but it was never a high-detail kit or well proportioned

-

1964 Econoline

OldNYJim replied to Tcoat's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Great work so far - really impressive! Love the stance, and the effort you’re going to with those doors! -

That’s awesome - really impressive work!

-

Pity - I got excited and thought this was getting a reissue…

-

Thanks for all the great pics - really enjoyed them! That purple 40 delivery looks amazing! And the Batmobile gasser stood out to me too

-

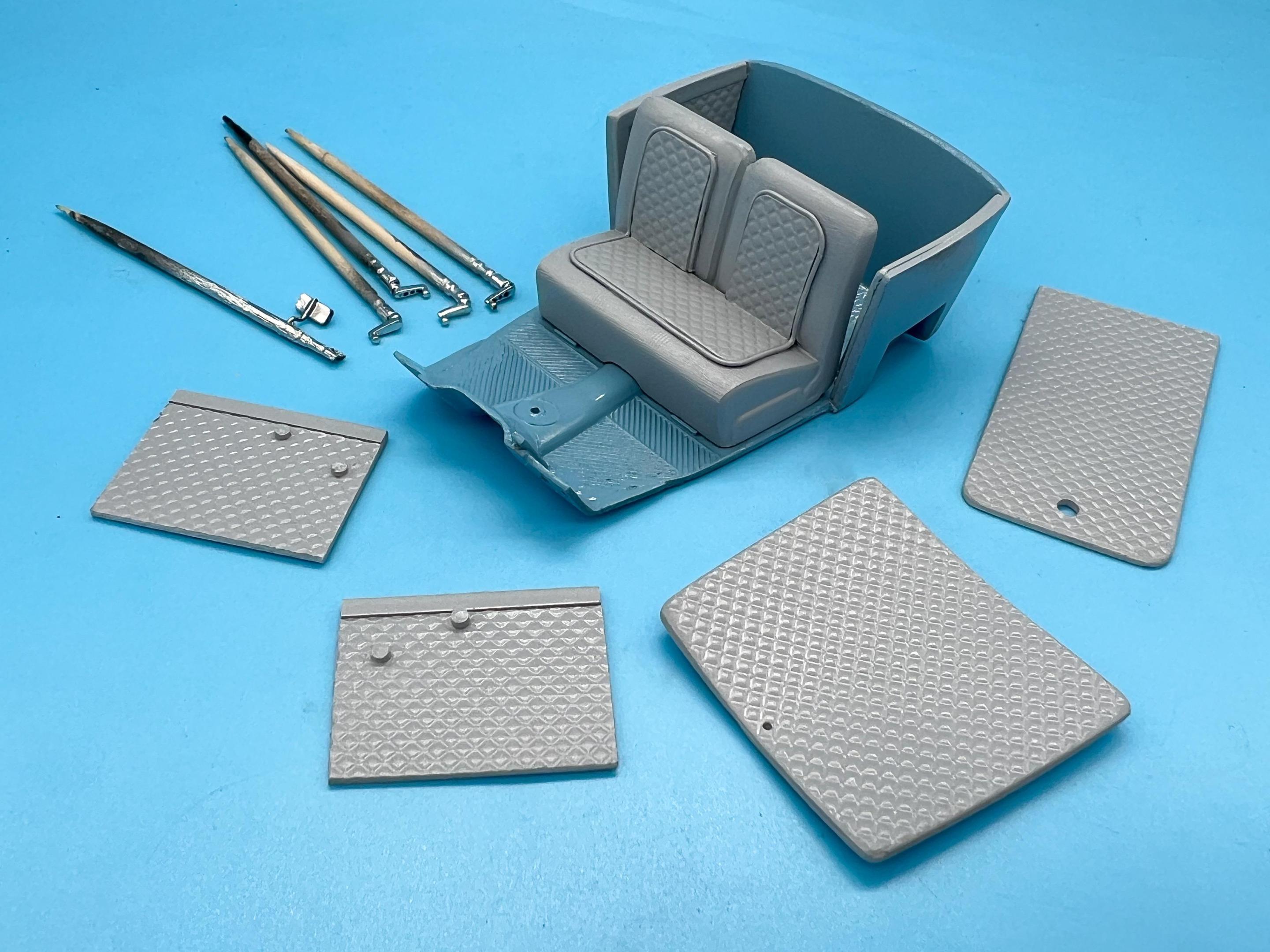

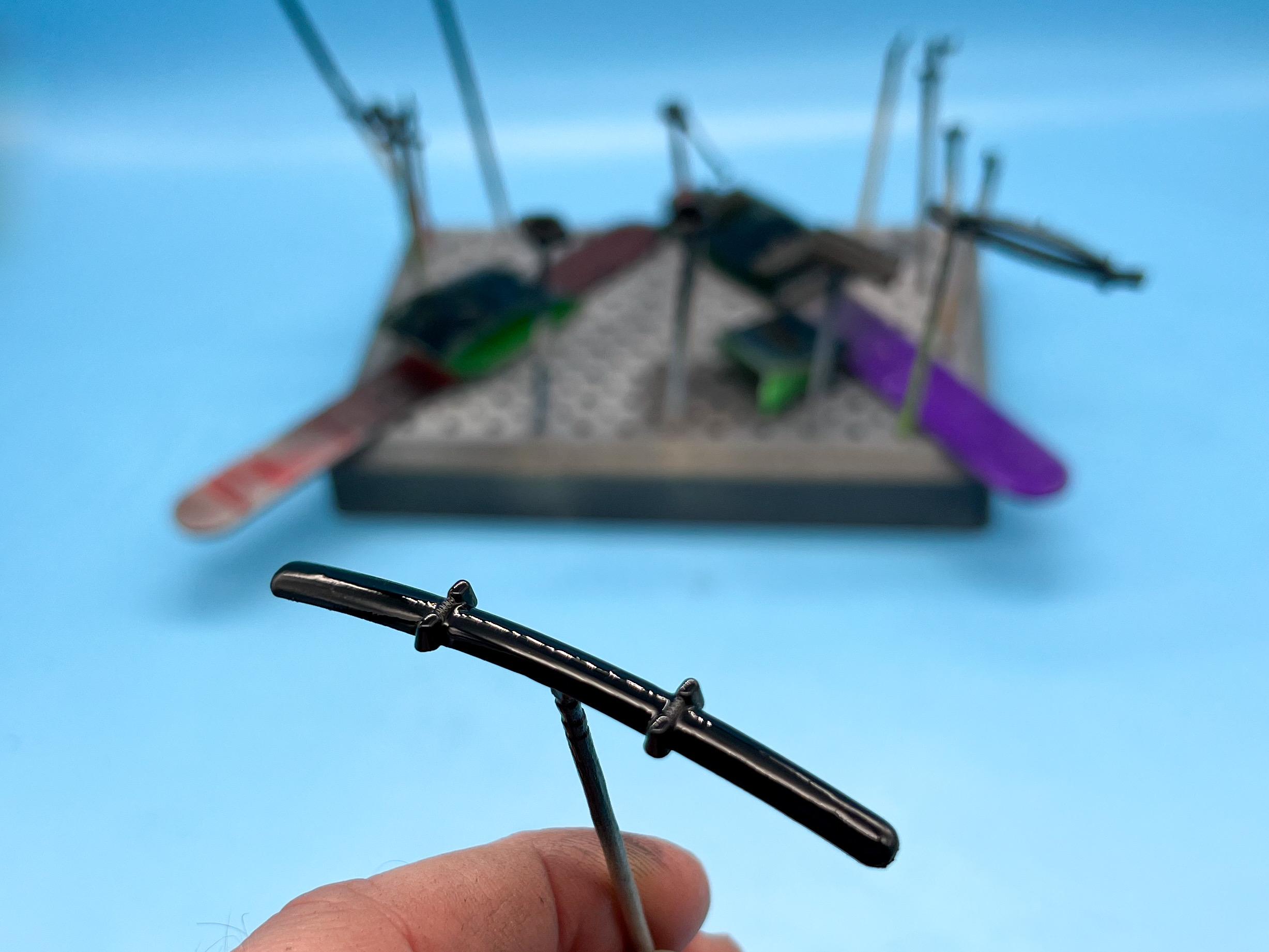

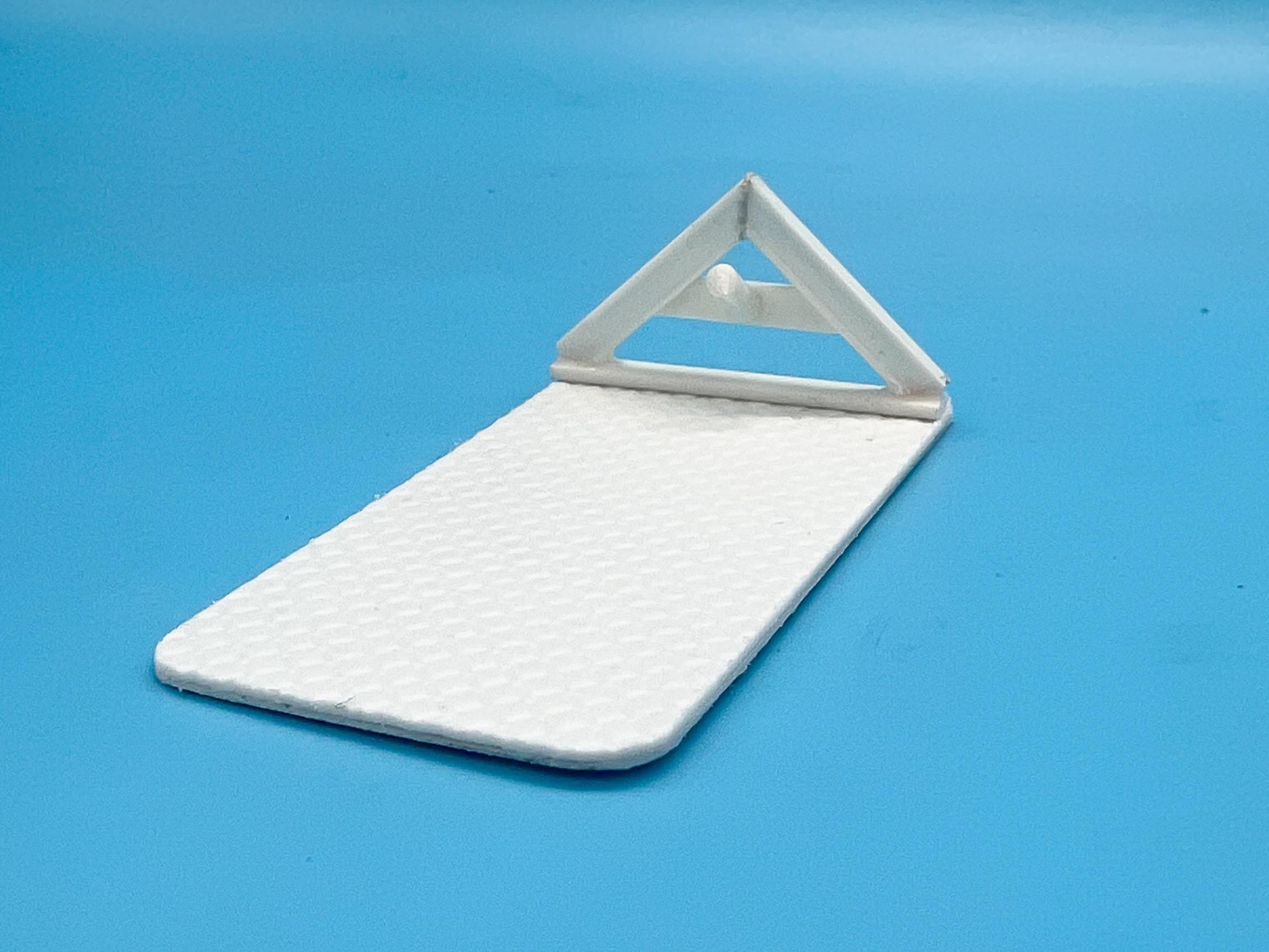

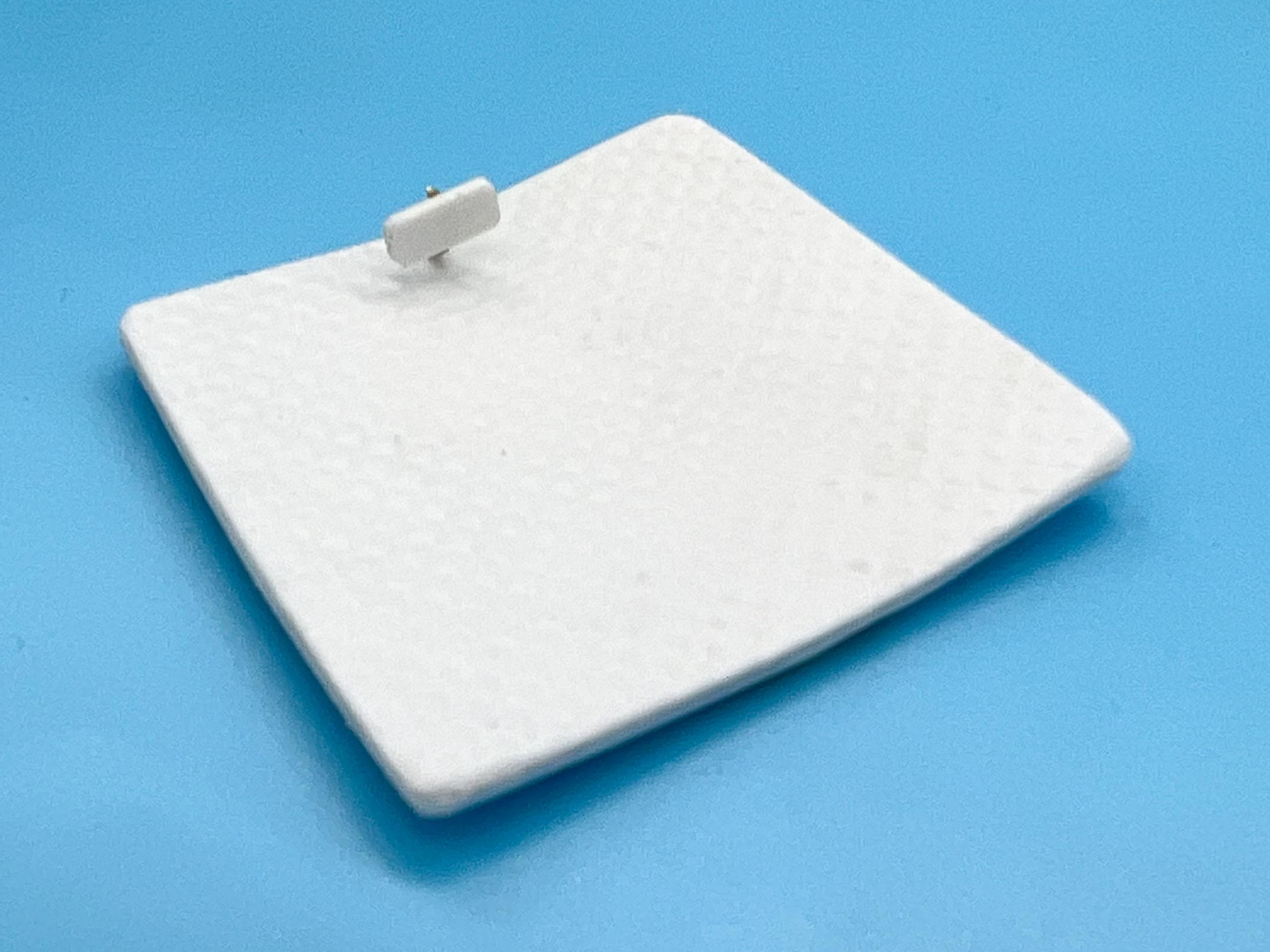

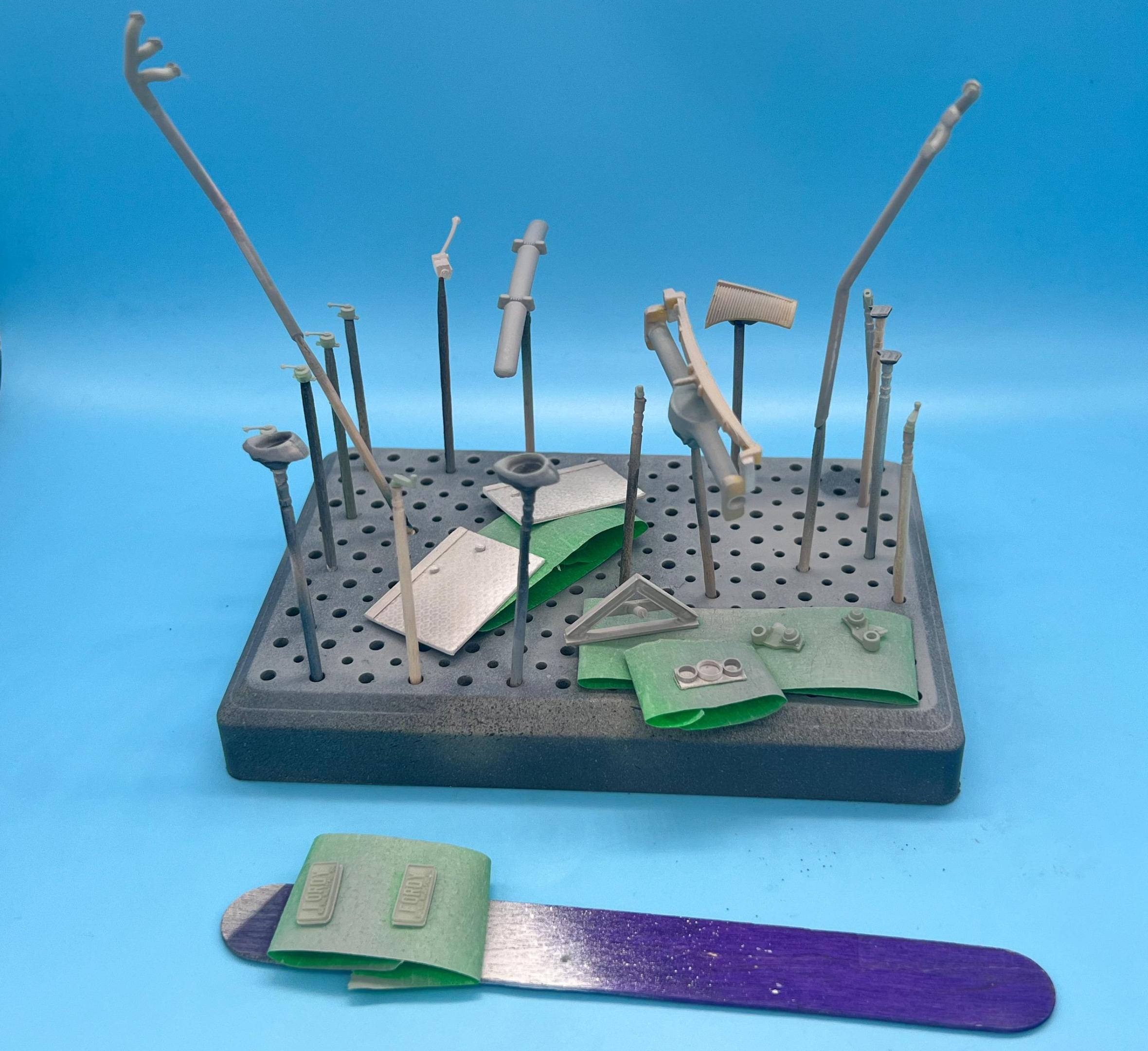

Thanks buddy! That’s true, yeah! Sometimes that can be an advantage (it’s easy to hide a not-so-great interior by just shooting it black), but I’m gonna go white with this one so adding some texture will definitely add a little… Thanks brother Carl! Ya got that right! Haha!! I had been putting off figuring that out properly but eventually ran out of other stuff to do…appreciate your guidance the other night! Thank you!! And thank you too!! I’ve been plugging away at this thing some more, had a few little projects to handle before I can get down to some serious painting. First up, these 40s have a couple of crossmembers or braces in the trunk that I wanted to add…the kit design doesn’t allow me to easily replicate them exactly, as best I can tell, but I made something inspired by the real part anyway… That little peg on front holds the spare wheel… Made a headliner - laminated some styrene sheet to get it to match the curve of the roof then added some more of that thin diamond sheet styrene to make it match everything else… Designed and printed year-correct license plates…the tagline on the bottom references the 1940 World’s Fair but I’m not sure if that’ll be visible after paint…it was tough even getting a photograph of it ? Designed and printed some friction shocks too - I forgot to get a ‘studio’ pic of these but here’s one on my finger… I was gonna make a little Lady Liberty to hide in there somewhere - maybe on the dash as an East-coast take on one of those dancing hula girls but getting one to scale is tricky. Here’s my smallest successful print so far, but it’s way too big for the project (but still tiny!) And the rest of the last couple of days was spent prepping and priming stuff…not the most exciting work, but it’s nice to be able to batch up a big group of parts and make some serious paint-progress…this is one of four racks of parts currently in progress… Thanks for looking…more soon!

-

I’m still enjoying your curated highlights @ea0863 - THANK YOU!! Something I’ve been enjoying in browsing through some of these myself is seeing how much the definition of a ‘period correct’ hot rod changes through the decades. There’s a BIG difference between the 80s interpretation of a traditional build compared to the 2000s. It’s interesting to me to see that paying homage to a particular period of hot rodding often still ended up with results that were influenced by the trends of the time when the car was actually built…

-

My wife has me saved in her cellphone as “Jim ❤️❤️”, with the hearts so she can see at an easy glance if it’s me who text/called her, or someone else. When she uses Siri to call me (using voicedialling whilst driving or whatever) she has to say “call Jim Red Heart Red Heart”. 90% of the time, Siri replies “Calling Pizza Hut” ??

-

Looks GREAT! Nice work!

-

The Hinman roadster, a study in rust update 1/18/23

OldNYJim replied to Bullybeef's topic in WIP: Model Cars

Really enjoyed reading through this thread - love a rusty hot rod! -

Thanks Carl! Funny thing is, I’m not totally a 40 Ford kinda guy…but now I’m working on this one I’ve got a tonne of ideas for others too! I think it’s less necessary with convertibles, you don’t gain as much because you can see the interior already - but I like how a build looks sitting there with the doors open too! Thank you sir! And thank YOU too! Next couple of days progress…I looked at a bunch of blue ‘n’ white early sixties 40s and sometimes they can look a bit more ‘custom’ and a bit less ‘hot rod’. So, today I spent some time messing with some door numbers…tried a bunch of ideas and settled back on the simplest one by the time I was done. Cut some masks: And shot my favorite opaque white, Tamiya matte acrylic. I think I like it! A little unusual, but not too radical for the era I’m going for, and stops it being just another blue traditional hot rod. Makes me think of an oval car, which is ok by me…I love seeing a little oval influence on a hot rod just as much as a drag influence… Once the paint has dried thoroughly I’ll start shooting some clear and getting ready for the polishing stage. Meanwhile, started some work on the interior…used a square pattern Evergreen sheet to make some faux diamond upholstery for the doors and seat inserts: And whilst the glue was drying 3D printed some little window cranks and door handles: Actually, I printed a bunch because I always seem to need door handles… With that done, I resin cast a Moon gas pedal, made a simple clutch and brake pedal (which I’ll accessorize with some photoetch when they’re painted) added some trim to the seats to finish them off and ended up about here: I’m going for an all-white interior, no two-tone…maybe a darker carpet color. Still plenty to do, but it’s all progress! Thanks for looking everyone!