-

Posts

39,253 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

What would a car modelers Hades be like:

Ace-Garageguy replied to GLMFAA1's topic in The Off-Topic Lounge

According to half the responses, I'm already in Hades. S'OK though. I've suspected that for some time. -

Rhyme with slime some other time, but have a taste of thyme while you climb to heights sublime.

-

What would a car modelers Hades be like:

Ace-Garageguy replied to GLMFAA1's topic in The Off-Topic Lounge

How 'bout every time you paint a body, thousands of little bugs land in it, so thick your model looks like it's growing hair? -

Electric NASCAR

Ace-Garageguy replied to CaddyDaddy's topic in General Automotive Talk (Trucks and Cars)

I dunno, but NASCAR's been a snoozefest to me for years, ever since all the cars became pretty much the same, with nothing "production" or "stock" about 'em. BO-ring. BO-ring squared if they're running on batteries. But hey...that's just me. I've got gasoline running in my veins. -

I got my gutters cleaned before the cataclysmic downpour that was forecast for this afternoon...and so far has failed to materialize, and judging by the live radar, ain'ta gonna.

-

Peg-leg pants must be for pirates with peg-legs.

-

If I'm honest with myself, part of my continuing to add to an already overflowing collection of hobby stuff (not just car models) is an aversion to becoming like so many retired folks I know who seem to have no interests once they quit work, and often complain of "having nothing to do". I have no comprehension of what that must feel like. I've always had way more interests and aspirations than I had time for, and thanks to the roll of the dice, I'm still healthy and fit enough to indulge my primary interests...building full-scale cars, road-tripping and hiking/exploring/camping/boating...for what looks from here as the foreseeable future. HOWEVER...an injury or a health issue could change all that in an instant, so having indoor hobbies to fall back on gives me a measure of security from finding myself incapacitated with "nothing to do". And in the meantime, I enjoy them immensely "in the now", in spare time (which I don't have much of these days), so I make no excuses. When I'm gone, there's a flying RC club in my little town out west, and they'll get my aviation stuff to do with as they please. There's also a railroad museum with a nice HO layout and a local club, and they'll get my train stuff. Far as the car stuff goes, we'll just have to see. The big-car stuff like machine tools and vintage parts I'll likely leave to the local high school's vocational program. The car models...pretty well thought out too. The most valuable ones, those that are actually worth listing on eBay, are labeled as such, and can be easily liquidated by my primary heir...along with the real cars. The remainder can be dumped at consignment shops to bring whatever they'll bring, or given to shops that support "worthy" causes. All OK. As long as they don't go in a dumpster or a trash fire, it makes no difference to me, and my will so stipulates.

-

Good eye, excellent points, and the Italeri version does the same thing but to a somewhat lesser degree. It's as though all the tooling designers "interpreted" the car through their idea of what a sports car was "supposed" to look like, rather than really trying hard to represent what's actually there. It's often the subtle design elements that make iconic cars as striking as they are, and it's also very often the subtleties that ham-handed kit designers miss...making the model look somehow "off".

-

Yup, nice work on the '36s. Is that a diecast Auburn boat-tail? It looks big to be the old Pyro/Lindberg kit, but I could be wrong.

-

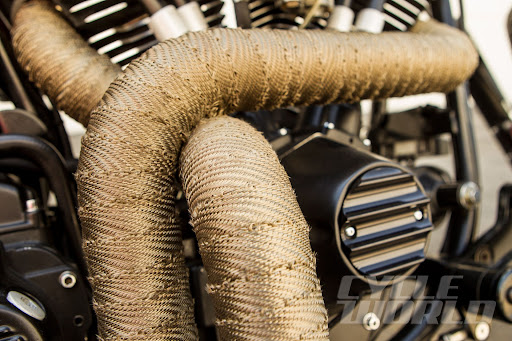

The thing to remember is that, though it's a very heavy texture in 1:1... ...the smaller scale you get, the more the texture becomes invisible...

-

One-Off Quiz #43 - Finished

Ace-Garageguy replied to carsntrucks4you's topic in Real or Model? / Auto ID Quiz

Very often some men seem to need huge vehicles to compensate for something or other. Perhaps this is the reverse. -

Trade my non chrome engines for chrome ones.

Ace-Garageguy replied to rssschris's topic in Trading Post

I have the chrome parts-pack versions you want. PM me. -

Turned out I still have one of the AMT/Ertl kits here after all. Comparing to Matt's pix of a real car, the most jarring problem on the AMT kit is the overall roof profile, followed by the windshield opening, and then the shape of the front wheel arches. The nose / grille opening could use a little work too...particularly the lower apron. Unfortunately, there's an anti-squash-while-in-the-box reinforcement molded into the center of the windshield opening, and its effect is to pull the center of the upper line of the windshield down somewhat, spoiling the opening entirely. There's a problem with how the top of the rear fender line falls away too. It's too high at the rear, and as I look at it more critically, it almost looks like whoever did the pre-tooling master started with a Cobra body, and kinda massaged it into a rough approximation of the Ferrari, rather than scaling from a real car, or carefully interpolating from photos. Another problem with the AMT offering is that the molding of the whole thing is kinda "soft", and some aggressive block sanding, followed by re-scribing most everything, would help too. It's all doable, no single mod is a deal breaker, and the guts are reasonably OK...so as far as I'm concerned, it's a worthwhile project. The Gunze kit has errors too, one very obvious one being the distance from the top of the front wheel-arch to the top of the fender. The center of the top of the Gunze windshield opening is pulled down too. As I've said, there are significant errors on most every Ferrari kit I've ever looked at carefully. I have every 250 GTO kit there is, and not one of them is really right as far as I recall.

-

I think the cloth tape is better for larger scales, old-style cheap thin white masking tape, painted/weathered for the smaller scales. This is not based on personal experience, but rather on looking critically at other people's models.

-

"Left out in the rain" is no way to treat bare steel parts.

-

Favorite Obscure or Discovered Music Album

Ace-Garageguy replied to afx's topic in The Off-Topic Lounge

Sorry...not an album...but it sure makes me want to work on a fast old car... -

Speed parts identification, and period useage

Ace-Garageguy replied to tbill's topic in Model Building Questions and Answers

Boy, are we old. "Packard" wire was the hard-core hot setup, stranded copper core, no-noise-suppression...with Rajah. -

Speed parts identification, and period useage

Ace-Garageguy replied to tbill's topic in Model Building Questions and Answers

https://www.trifive.com/threads/when-did-yellow-spark-plug-wires-come-out.232255/ -

Electric NASCAR

Ace-Garageguy replied to CaddyDaddy's topic in General Automotive Talk (Trucks and Cars)

-

Style and fashion are two entirely different things, and a woman can have wonderful style without wearing anything that's "in fashion".

-

I think the Esci kit gets a worse rap than it really deserves. I don't have the kits handy, but I once did extensive notes as to what corrections I'd make to get it "good enough", and it really wasn't all that extensive...and I'm one critical old geezer far as line and proportion go. I think the comparison shots pretty well bear that out. It's not terrible. Thing is though, jus' 'bout every Ferrari kit I've looked at closely has at least one glaring error, so either you fix them right, compromise on "good enough" if you can capture the general "look" of a real one, throw them out, sell them on, or build an OOB wonky looking model and live with it. Other thing...most people just don't notice there's anything wrong with lotsa models anyway.

-

Wah wah wah...but hobby-item resellers who find garage-sale models with a few loose parts and decide to "fix" them prior to listing, and whose phone photos don't really show the gloo-obliterated details and finger-smears and blobs, or the 40-grit sanding scratches...they just drive me nuts. There are some really sweet deals to be had buying models from non-modelers, but it's always a roll of the dice. If you have the skills of a 5-year old, PLEASE just leave things alone. And try to think through that a heavy die-cast model with tiny wire and lost-wax and plastic details won't ship damage-free if all you do is bubble-wrap it and shove it loosely in a box where it can bang around as the PO chimps play soccer with it.