-

Posts

4,500 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by gotnitro?

-

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Charlie ! Broke out the angle finder from my remodeling tools to make both sides symmetrical, worked awesome -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

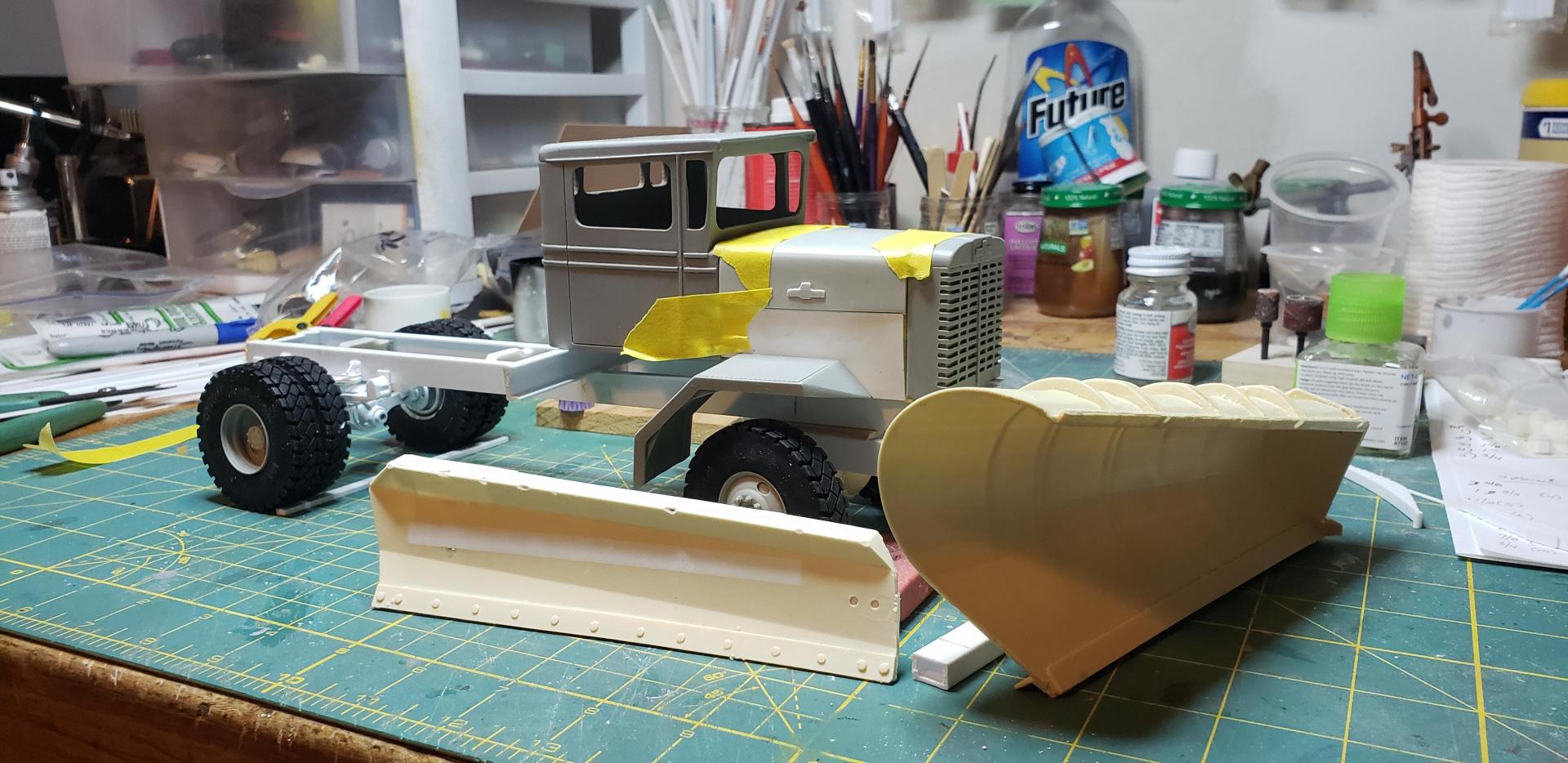

Yeah looks like I could tweak the windshield location, and the trim would be easy to remove and replace . I'll putter w when I finish the sander , I rebuilt the body w wider angle . The supports still have to be installed . heres the hopper behind the cab , definitely looks better ...no more anorexic model now ! -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Okay I see what your referring to on the cab . Still being the only available Oshkosh cab, its gonna make for an interesting project ! Thanks for input though, I may decide to tweak it , or the next one that's gonna have a Sicard snowblower -

Looking awesome Tom ! Really full of eye candy

-

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks..guess I'm not sure what your referring to about the cab. It's a P series cab usually used on cement mixers, but will work for the plow..especially since it's the only available option ! I'm not aiming for 100 percent accuracy -

Issue #206, Contest Issue, MAILED!!!

gotnitro? replied to Gregg's topic in General Automotive Talk (Trucks and Cars)

Hobby shop in New York had several copies in the rack, was super excited to pick one up Please drop the black background photos...the details were impossible to see , really disappointed since they were immaculate builds from John Teresi...and the gsl shots were similar Just my 2 cents -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Charles I noticed the vertical shape also. I used the cab for reference judging how far out the hopper extended past the corners. I took a look back at my photos, and your absolutely right, the hopper is definitely narrow.i REALLY appreciate your feedback and will correct the sides . -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks alot DJ ! Building replicas of these service trucks is very enjoyable, and only possible with our aftermarket support! Thanks Brian ! I've been steadily puttering with the sander body , wish I had about 48 hrs more per day lol. Time seems to fly by while I'm building, realizing its after 11pm and alarm sounds at 5 am really stalls my progress . Getting older sleep is becoming more a necessity -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

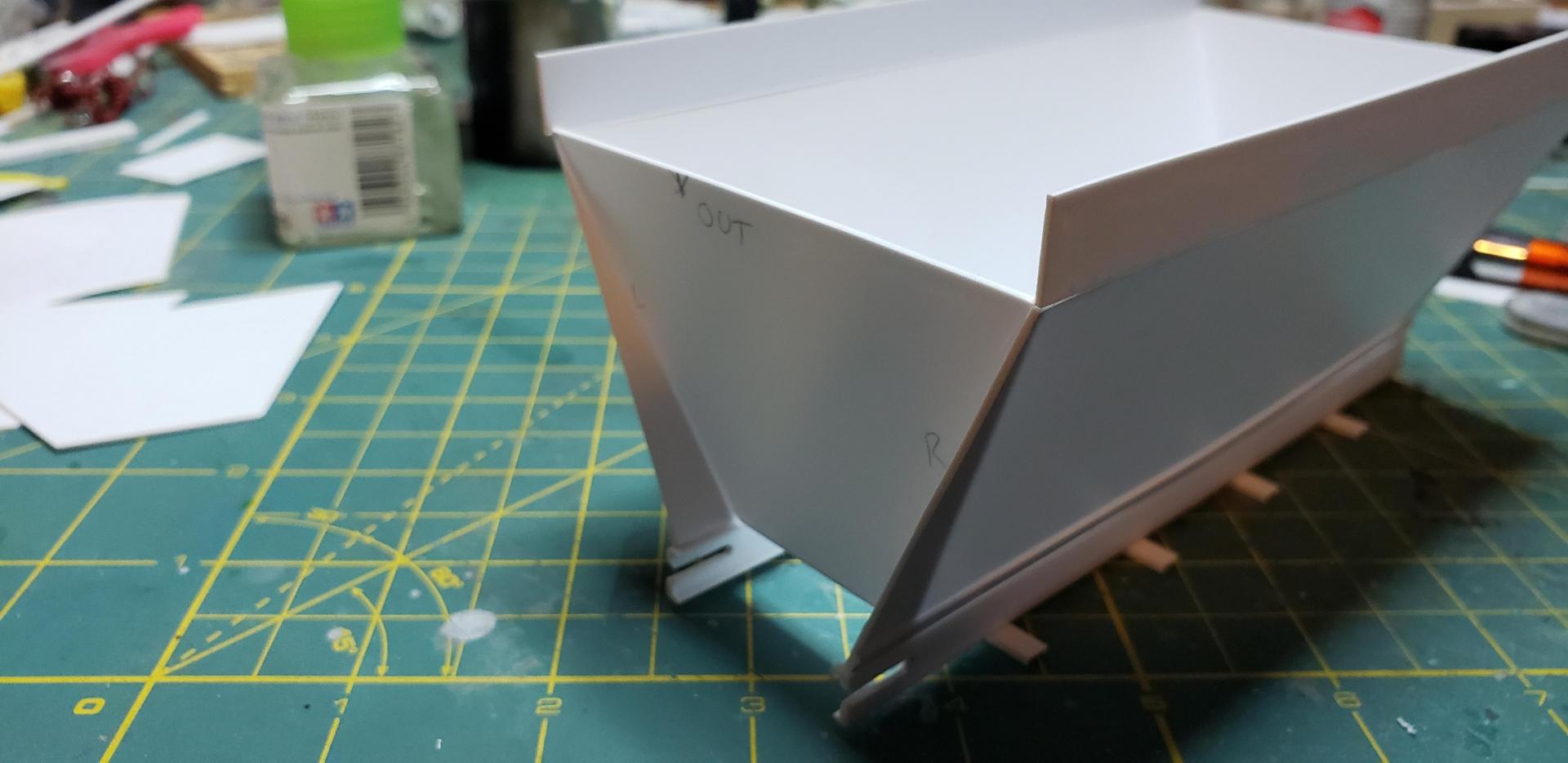

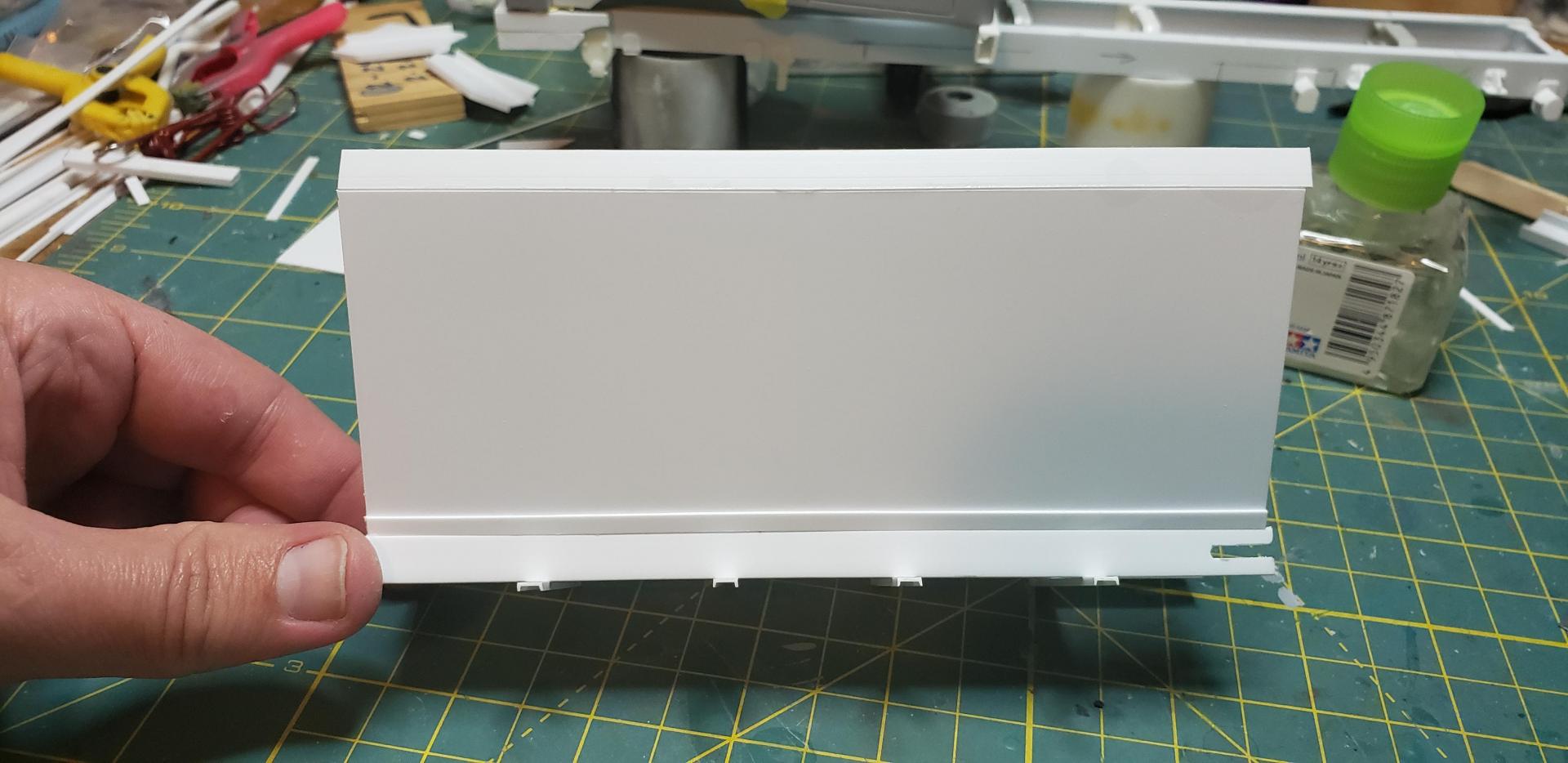

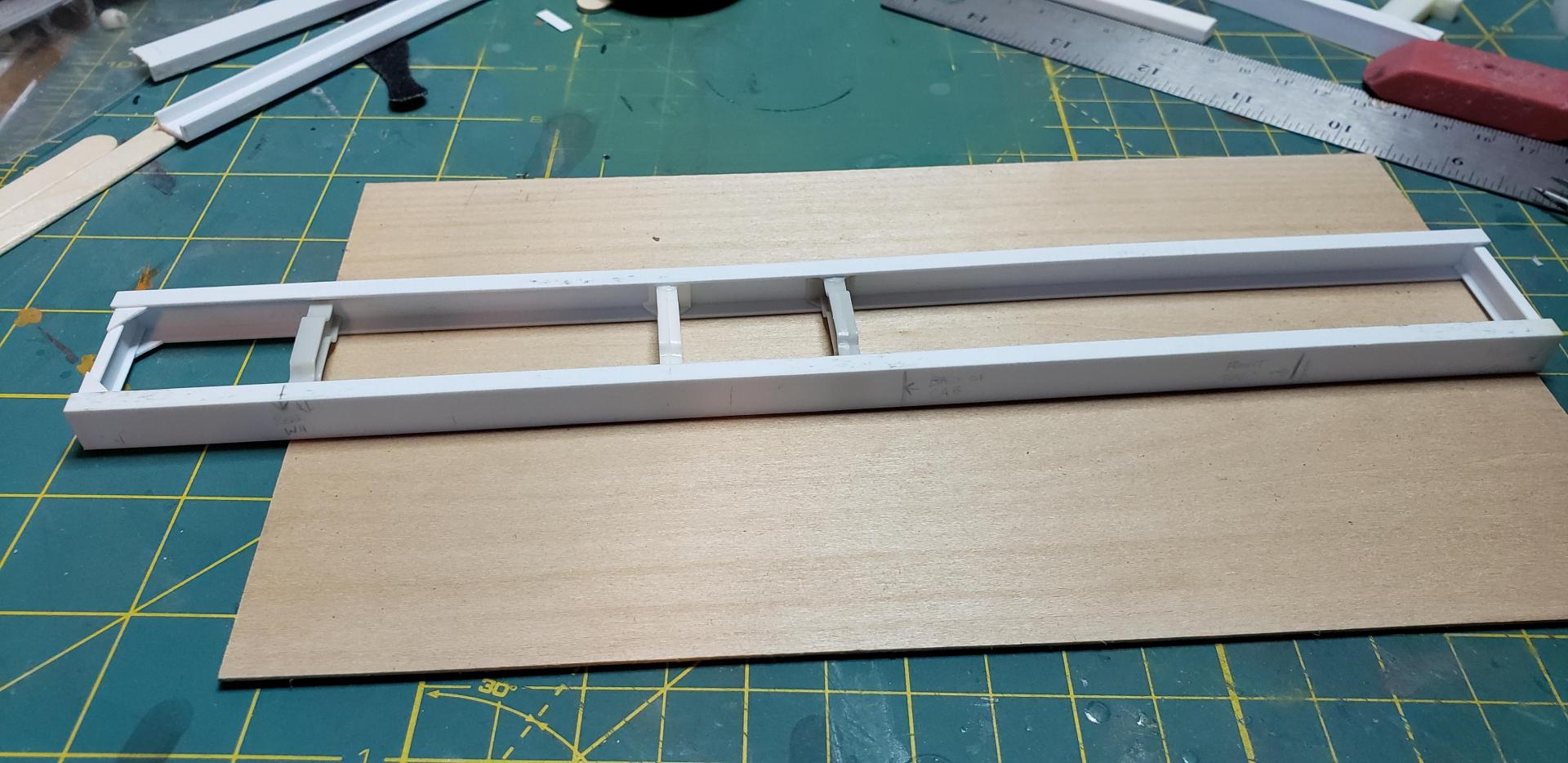

Added the rear / front bulkheads last night. Made a pattern from paper and tape then transferred to 030 " , fine tuning it for a tight fit .The ends both angled inwards , so I guessed at the angle . The bottom was left open for the eventual product conveyor to exit . Really looking forward to starting the spreader portion w the spreader wheel and housing. I was looking at some chain from Grant (sp?) Line for the conveyor -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

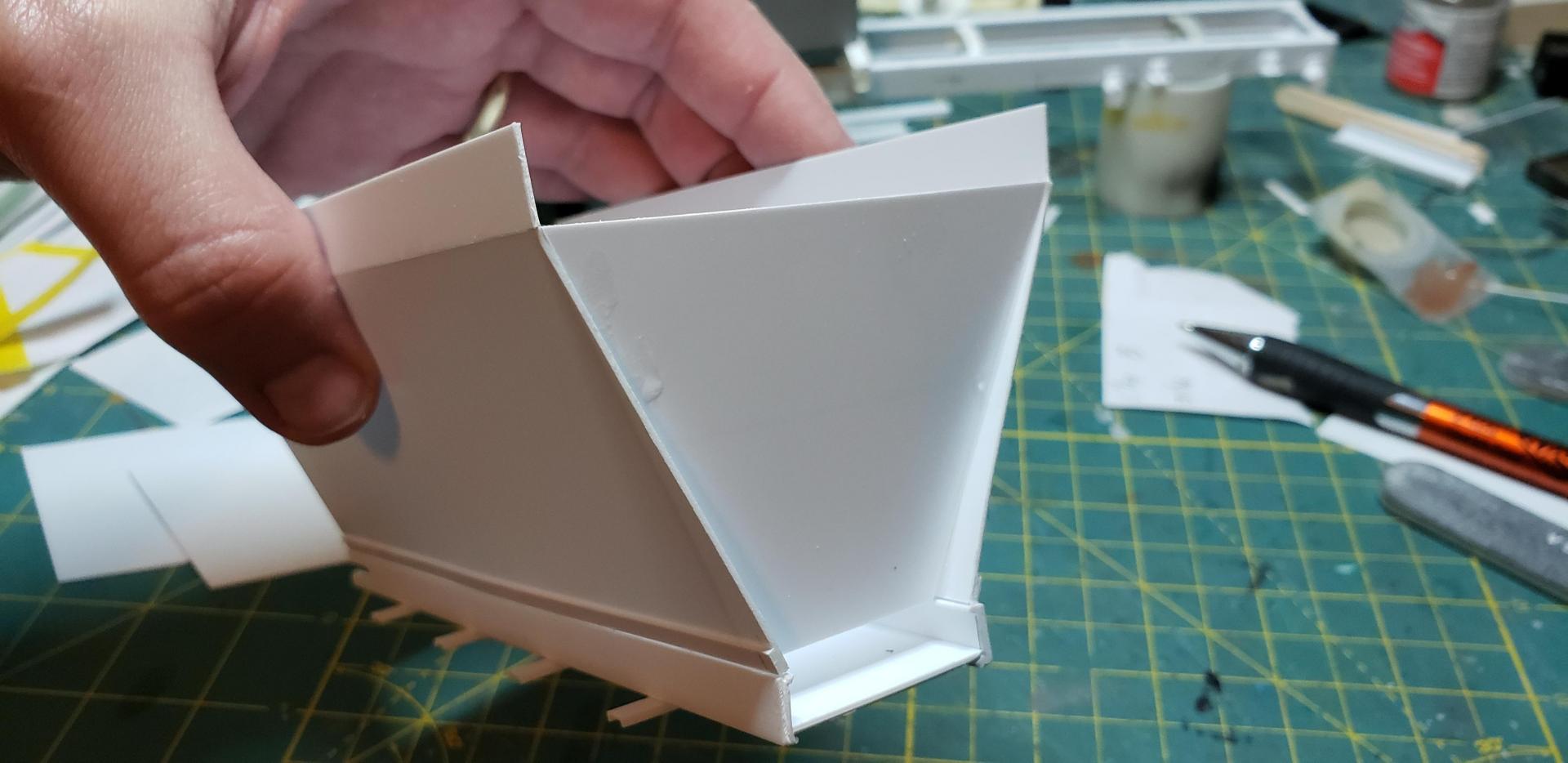

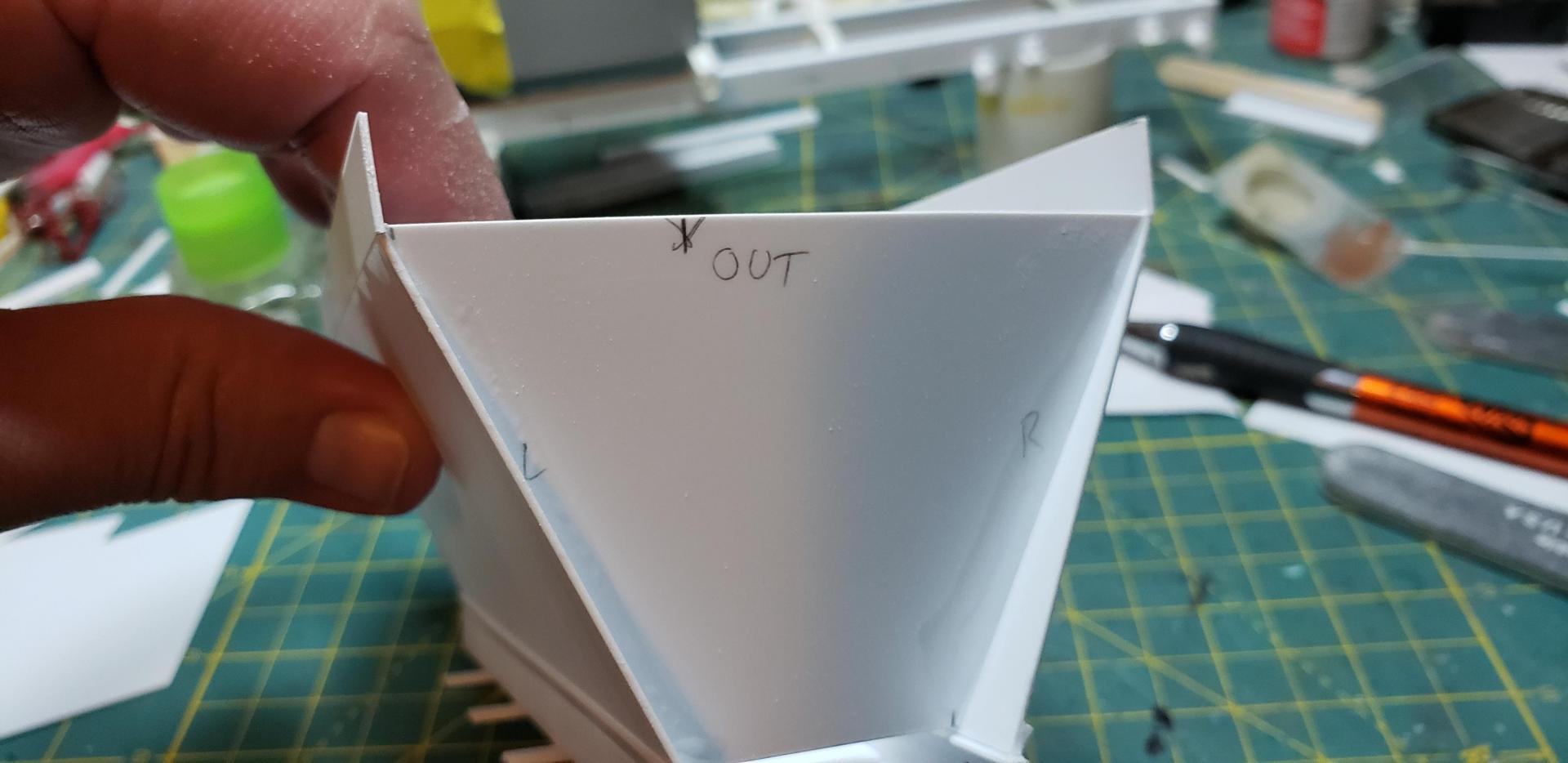

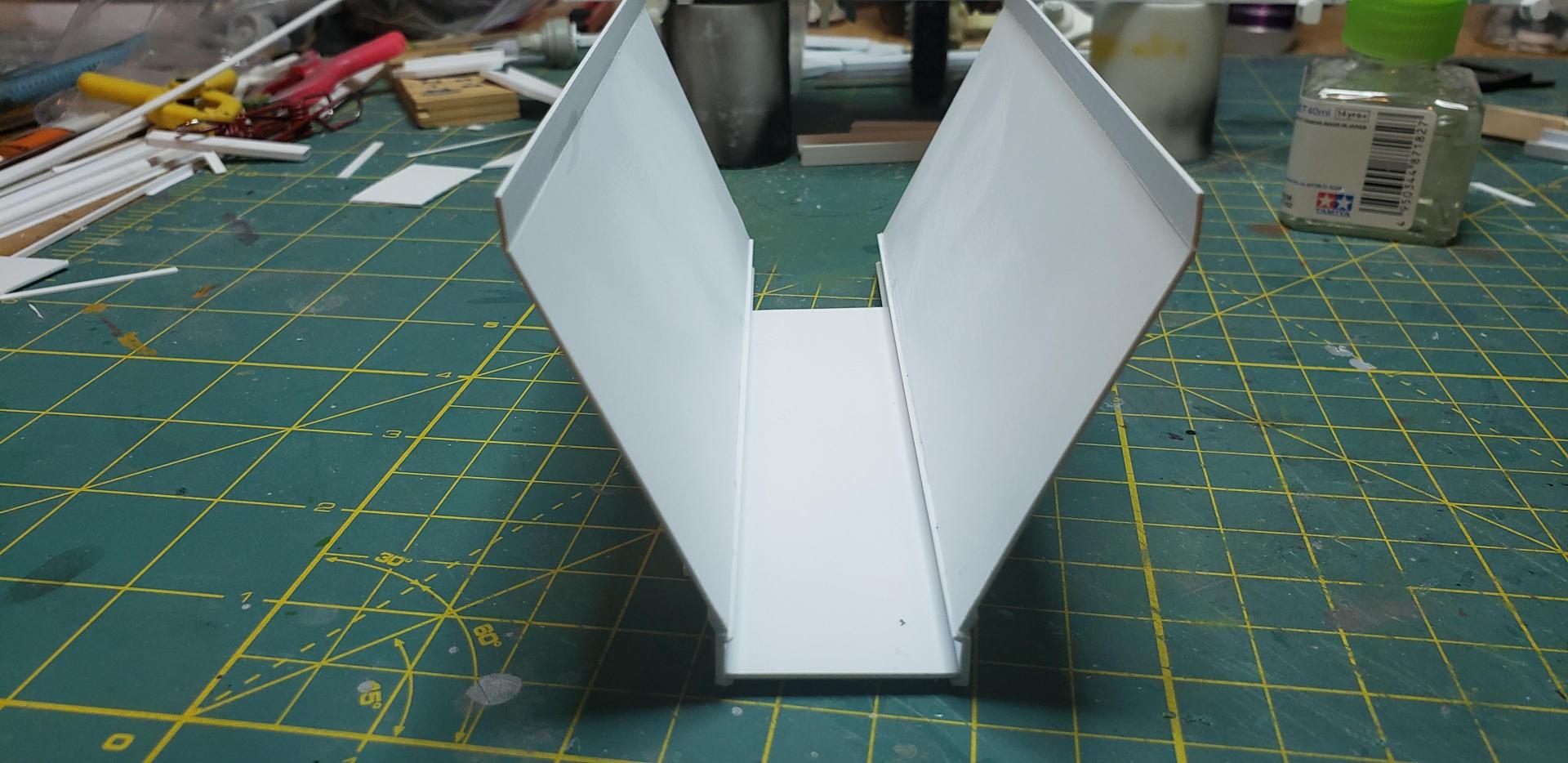

More white stuff turned into truck parts ! This time 030 sheet, and more c channel started making the Fontaine salt spreader body. I'll add a product conveyor chain to the floor later . I guessed at the angle using photos of the hopper -cab . The easier parts done, next the forward and rear bulkheads will be shaped Checking hopper w cab , something I check frequently. I noticed after this photo , the top strip looked too short, so off it went , being replaced by a section 3/8 wide a minor difference of 1/8 made it look better Sorry for the cluttered photos, that's side effect of in progress photos lol -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

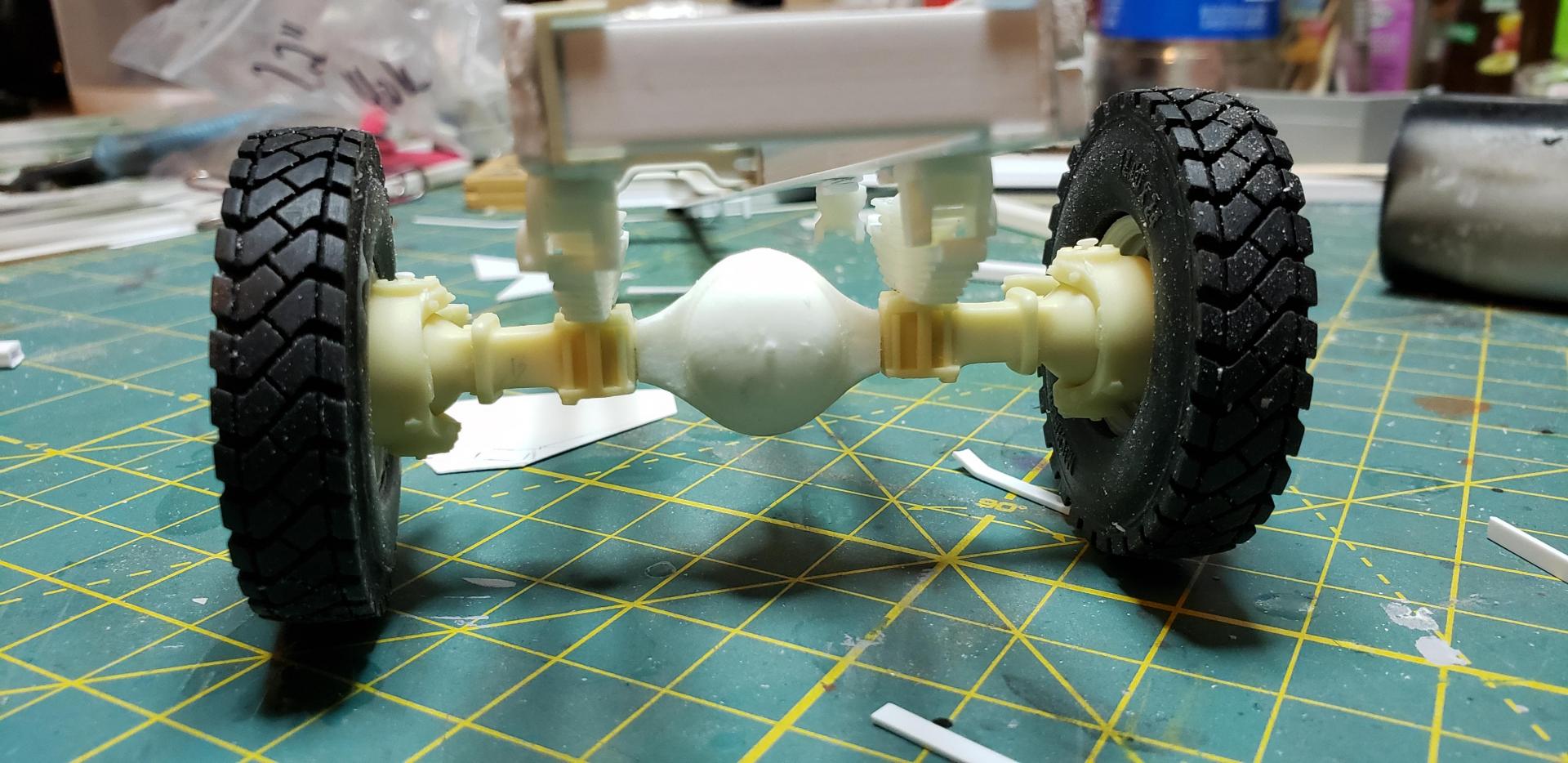

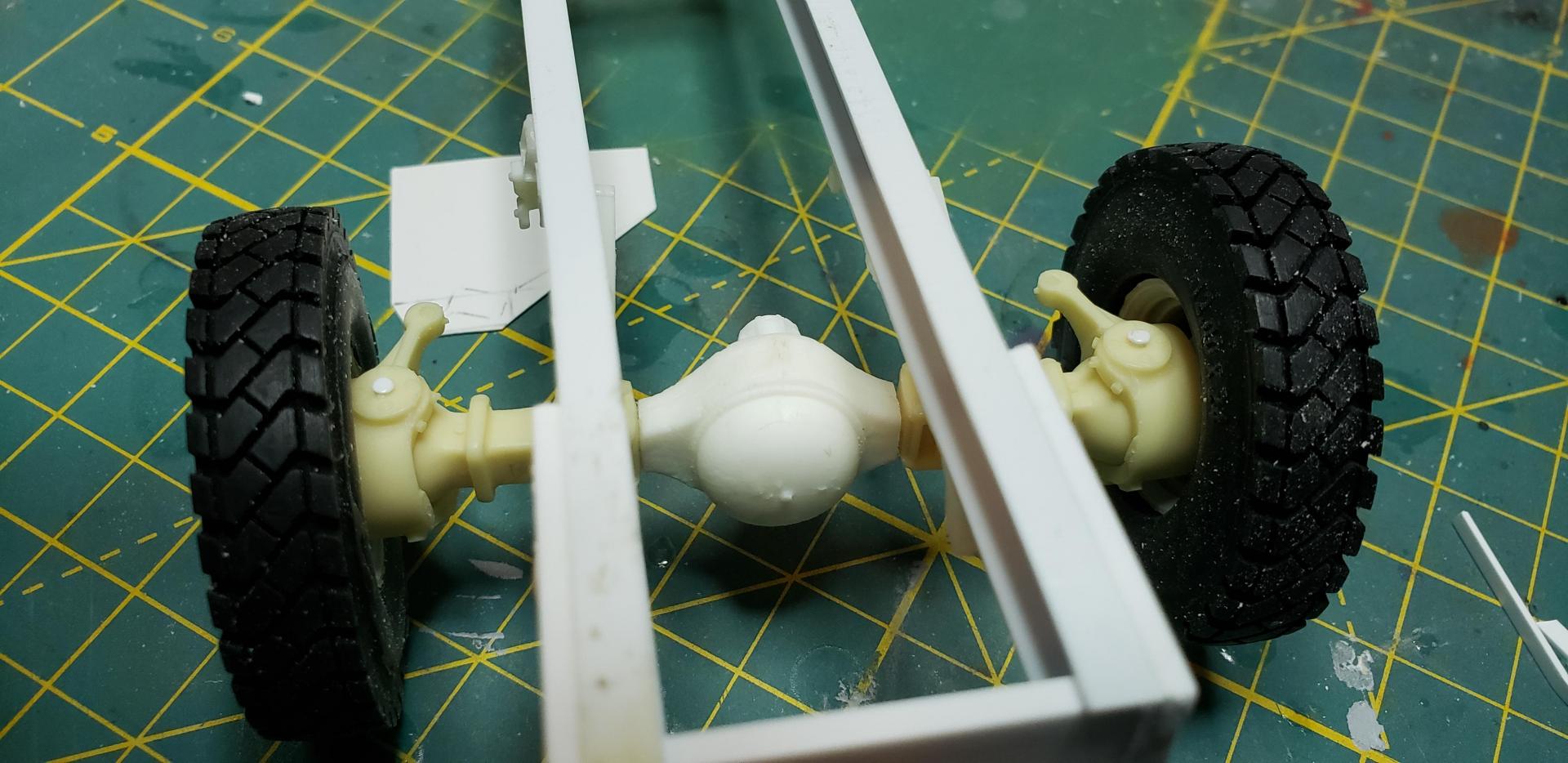

Hello Charles - the steering knuckles were removed from a kfs axle. The diff looked to large, but the steering components were perfect. Love the sailing vessel, beautiful Yeah, few memories from school days -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Awesome !!! I'd love to see a pic of their truck if ya get chance Always amazed seeing these trucks still around at numerous townships -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Right , people joke that the operators target mail boxes while clearing roads..just a joke -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I purchased the cab from Jamie during the summer, hes been working on casting more -

Oshkosh snow plow

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

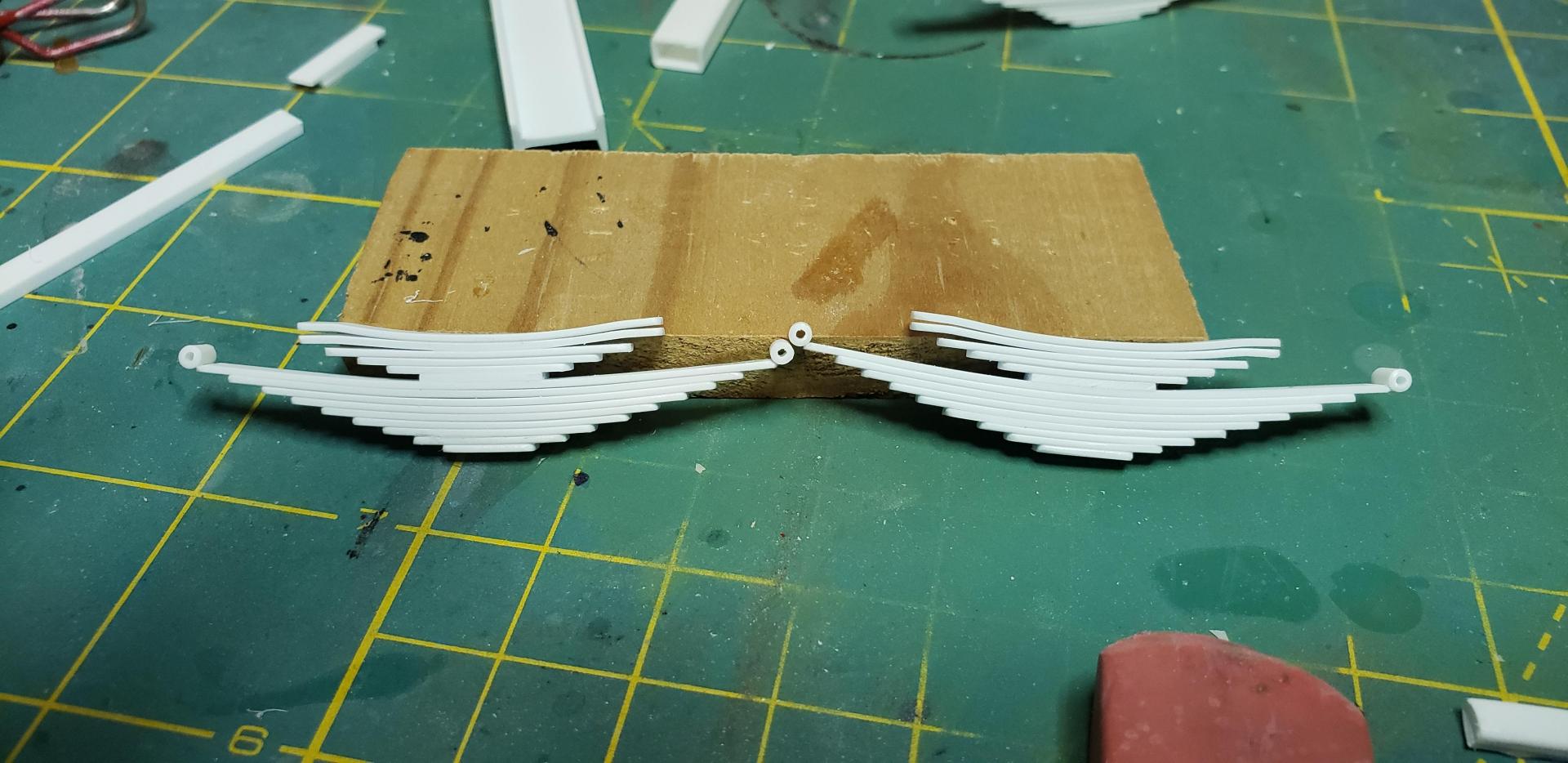

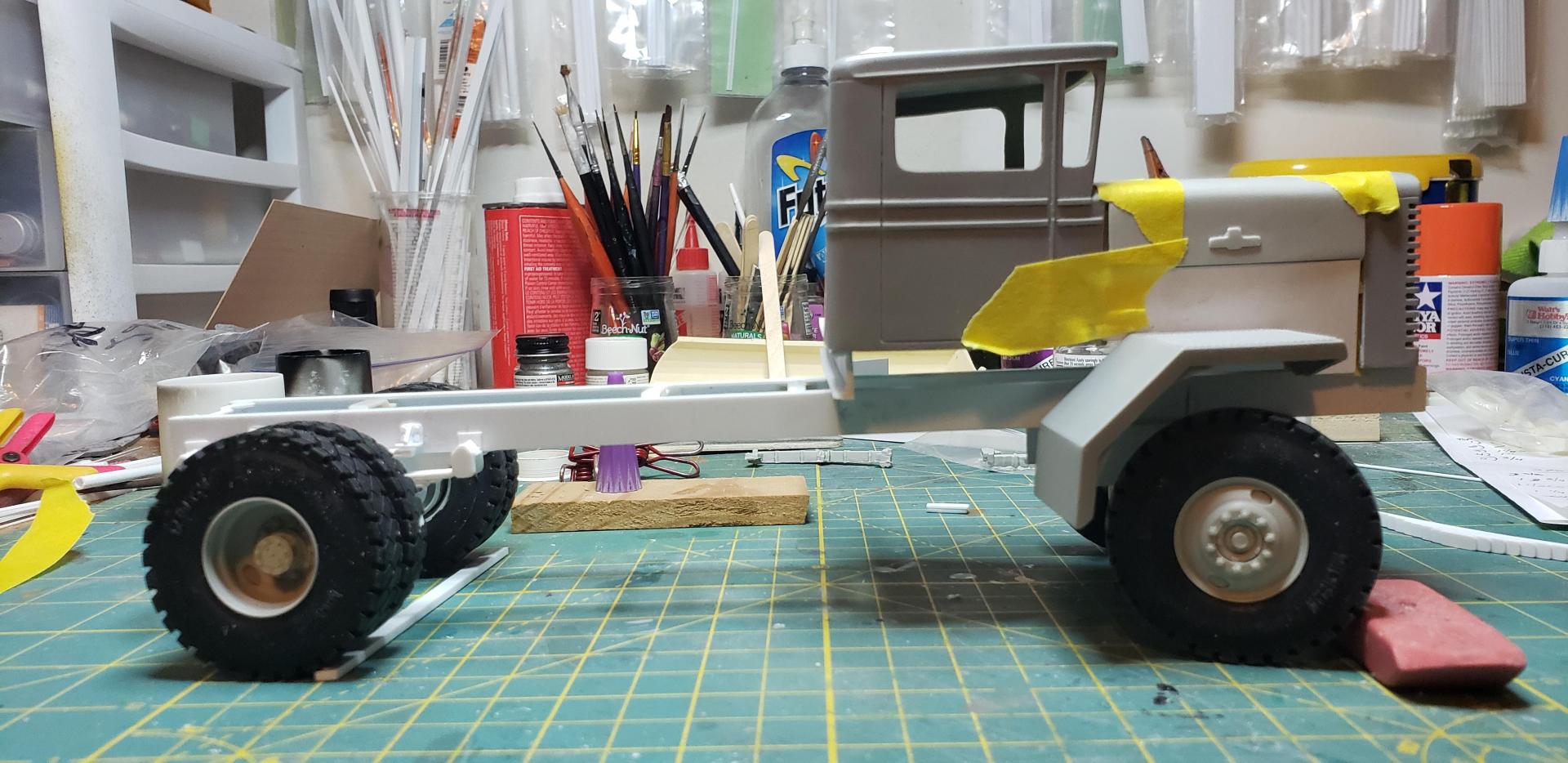

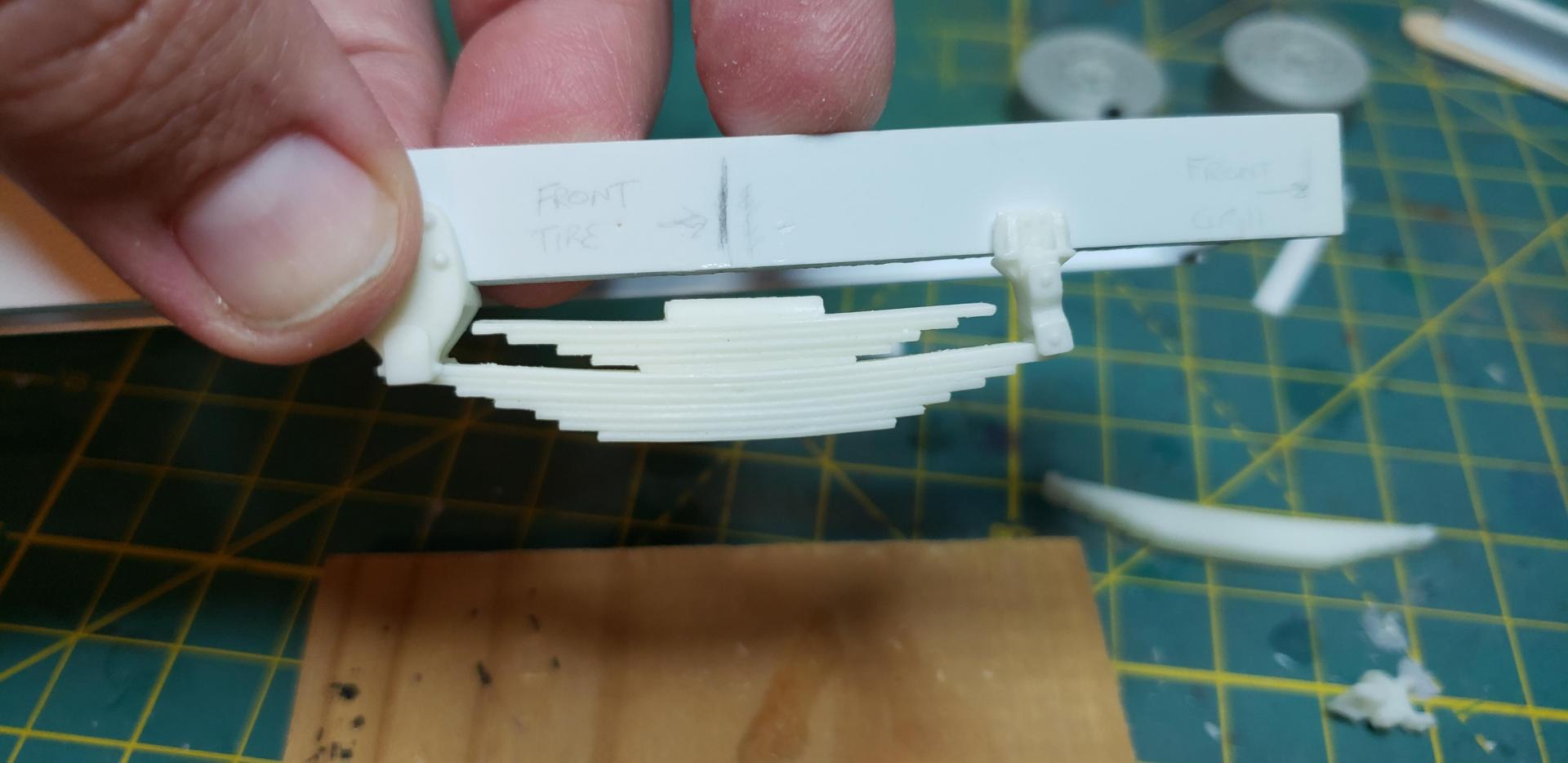

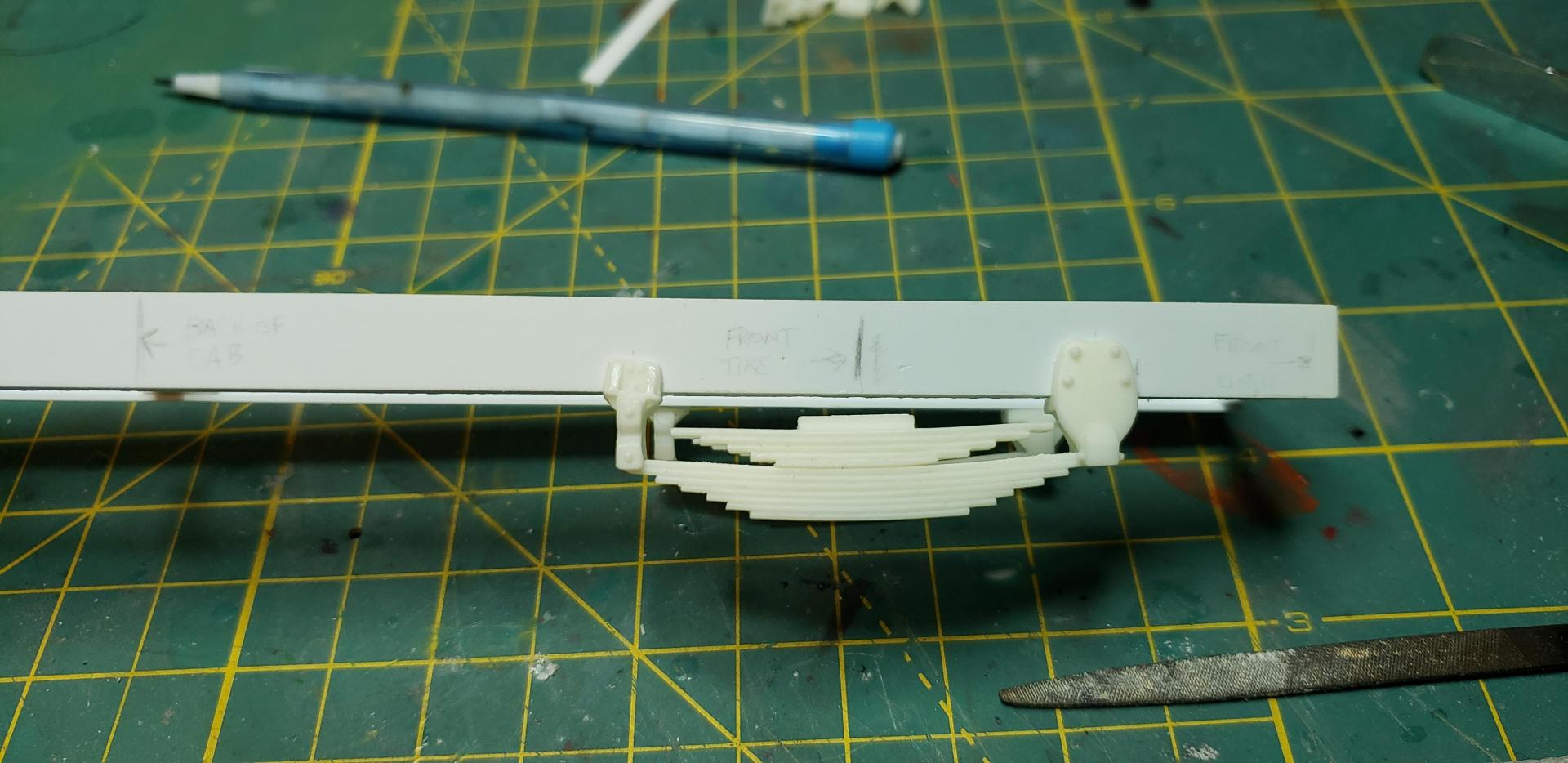

These trucks had heavy duty springs all around, so I scratchbuilt a stack using 030 x 156 evergreen strips, including the overload section. The eyelets are tube . The mock up axle was from parts but I'll swap it for a paystar, this one looks a little light duty for turning those tires . I propped the cab and plows for a look, nothing keeps the motivation going like seeing everything sitting together. I was grinning ear to ear right now , something about a rugged truck and that huge mailbox smasher was really working . Now the front axle..Gary surprised me w parts perfectly suited for this truck, perfectly cast spring stack w overload leaves, and beautifully cast mounts . 5 minutes after opening the package I had a proper susp. Yeah..I had the mounts flipped around , I sorted out my mistake haha ! I used the knuckles off a steerable axle and the gearbox from Gary's front axle to make my front diff. Sometimes you can have your cake and eat it too !!! Everything was drilled and wire glued inside to avoid issues later That's it for now thanks for following along , any comments welcome as always -

A project I wanted to tackle was a snowplow, and not just any plow..I wanted to build an Oshkosh snow plow . When the snow started falling here in Huskytown , the time had come !!! I started this build the same way I usually do, collect tons of actual photos and info about the truck. Luck was on my side because the local highway dept that owned my Brockway, also had one . The parts list required was large ! Luckily I had purchased the P series cab from Jamie at moluminum months ago before I knew what project it was to become. Normal kit tires wouldn't work for such a large truck, and then the elephant in the room..the Frink plow / wing assembly. The stars aligned w a chat w Ryan Pedone, he had cast a few more sets of his plow s , and a few weeks later the box arrived ! Beautiful parts filled the box. The tires posed another challenge, finding big tires like this truck used was sparse. A text to moluminum ended the hunt, Jamie had just finished a set of heavy duty truck tires, and they fit the 22 inch deuces I needed! That's a 20 inch drive next to them !! Time to get building!!!! Scratchbuild a frame from Gary Wallace's cnc rails, to assure everything was perfectly straight, drop a few parts box crossmember and I had a solid foundation

-

Don't be afraid to ask!

gotnitro? replied to Jantrix's topic in General Automotive Talk (Trucks and Cars)

I tend to build construction trucks, and have always been welcomed by the workers to take photos and chat trucks when I stop by the shops. I'm very respectful of their time , and always ask for permission to swing by if I forgot a photo angle. -

Autocar DK Dump and trailer

gotnitro? replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Beautiful work -

Hmmm? What to do???

gotnitro? replied to DrKerry's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very cool project!! Turned out fantastic -

Fantastic work KJ

-

KW W900 Day cab

gotnitro? replied to Oldmopars's topic in Model Trucks: Big Rigs and Heavy Equipment

Very nice, great color too -

Looks good from here ! Stretching frames used to be taboo..now its an everyday part of modelers skills that really makes for for interesting builds imo

- 13 replies

-

- freightliner

- coe

-

(and 2 more)

Tagged with:

-

Started a new master...

gotnitro? replied to Repstock's topic in Truck Aftermarket / Resin / 3D Printed

Beautiful work love the old buses ! -

Parts box tow truck

gotnitro? replied to BIGTRUCK's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Definitely like the wheel swap, it looks more in proportion now . Following