-

Posts

2,781 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Chariots of Fire

-

That is awesome, Lane. Thanks so much for posting! Those first three rigs are practically in my back yard! The C & O rig is now gone but theMarion rig is still in service. It has been rebuilt with a new body. The first and second rigs were built by the Maxim Motor Company of Middleboro, MA. The third rig was done in house by the Freetown FD. No idea abut the last one. I got an e-mail from AITM. The IH is being cast and will most likely be available as a package that will include the cab and hood, dashboard, floorboard and firewall, front bumper, running boards, steering wheel and steering column. More about this later as I will want to see the first pop to make sure it is ok.

-

Help with Washes

Chariots of Fire replied to andy12646's topic in Model Building Questions and Answers

Just don't rub too hard on the chrome part you want to keep. You might end up rubbing right through it. -

BMF Discolored?

Chariots of Fire replied to Markalister's topic in Model Building Questions and Answers

BMF does has an off bright tone to some extent but not to the extent that shows in your photo. Did you happen to coat it with clear afterward? I have not seen in the new BMF anything near that color. But others are right in saying it is not going to be really shiny like chrome plating. The new BMF is much more forgiving when you work with it and is much brighter than what you show. If it were me (and it is not) I'd pull off the old stuff and get a new supply and try again. I think the results would be more to your liking -

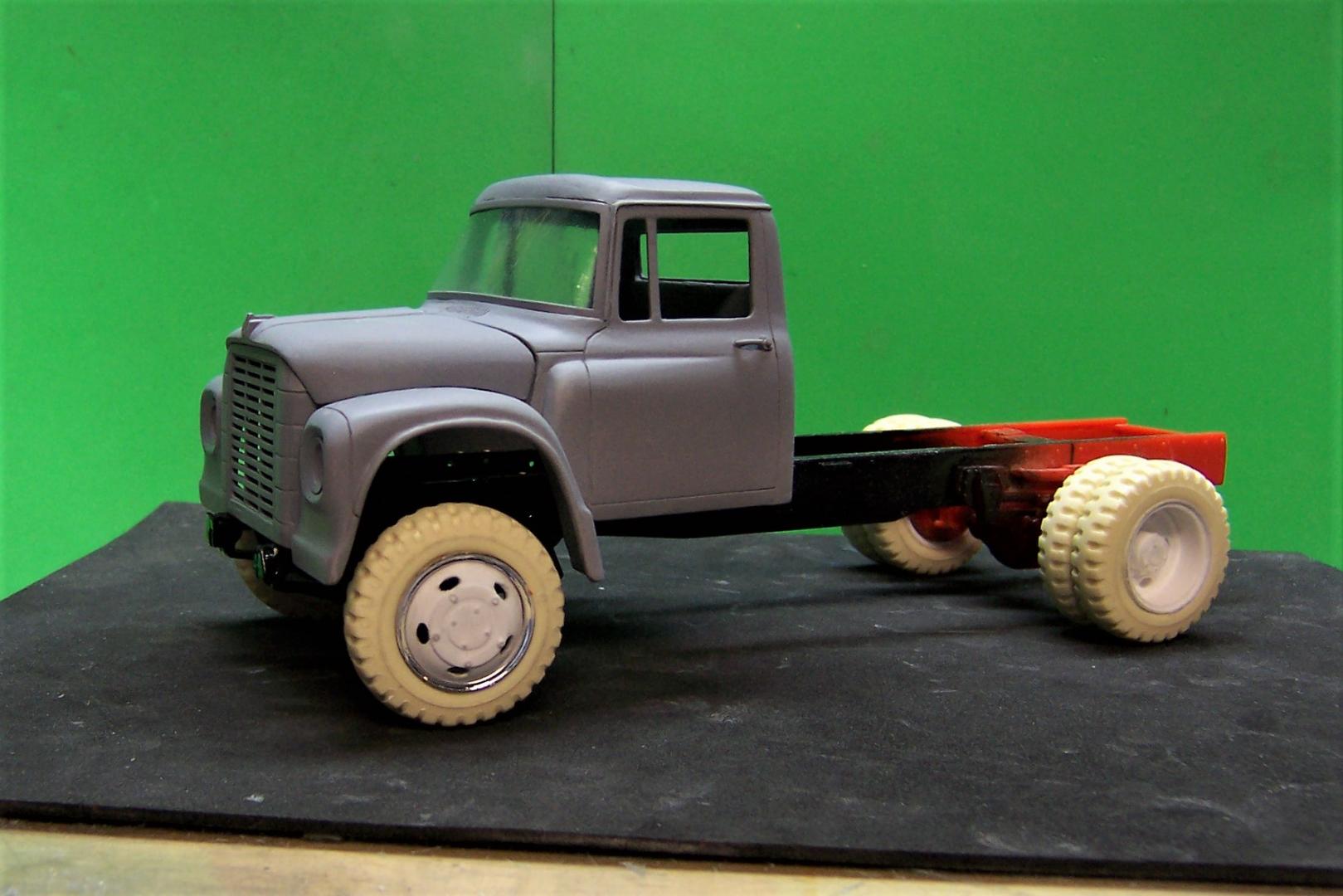

I think no matter which frame is used it will take some adjusting due to the close proximity of the front fenders to the front spring purchase. As far as the engine goes it will have to be a small V-8 as the distance between the grill and firewall is very short. I have not tried to see what might fit at this point. The one thing I do know is that the engine sits quite low in comparison to the top of the hood.

-

The Ford snowplow kit has the right spring arrangement for a single rear axle. The frame cross members would have to be changed up. But the front springs are a bit too long as the front spring attachment is right behind the fenders. So some substitution might be in order. Some exploring on line for IH chassis photos would be best to see what might be matched up the best.

-

-

Another Bay Stater says hello and welcome! Look forward to seeing some posts!

-

Returning to scale model building

Chariots of Fire replied to J.G.'s topic in Welcome! Introduce Yourself

Welcome back, Jerry. Hope to see some of your work when you get it ready. -

Still working on the windshield. I raised the top portion 1/16" and it looks a bit taller which I think is more correct. Going to let it sit for a while and see if I feel the same about it in a couple of days. Still some cleanup to do. It's amazing what shows up when you take photos! Hosted on Fotki Hosted on Fotki

-

Been making some minor adjustments to the top of the cab and I think now it is there! Study of the photos of the real thing from various points of view gave me a better feel for what it should look like. The hood also has been shortened a bit to draw it back. The separation line between the center piece of the hood and the butterfly sections has been cut in. A third try at a buck for vacu-forming the windshield finally gave satisfactory results. It was carved from Renshape and coated with Aero-Glos dope to really smooth it out. The windshield fits nicely behind the brass molding without any glue. And finally some interior door panels have been made and the dashboard basics are done. The dash will fit inside up against the bottom of the brass molding. Next are some interior fender pieces.

-

1974 Dodge Bighorn - Done!!!

Chariots of Fire replied to landman's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looking at the photo of the cab that is upside down it looks like one fender is not aligned with the other and that warps the grill. Can one fender be moved either forward or back to square it up? Major adjustment for sure but it would take the warp out of it. It would take a razor saw to remove one fender and then re-position it. -

Prototype Loader Doosan

Chariots of Fire replied to mackd's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Can't see photos from Photobucket. -

I'm still working on how to perfect the top of the cab. It has been a project to fill, sand, fill some more and work at the shape. I think it is almost there. Any advice you can give to improve it would be appreciated. I have the cab sitting on a 4x4 chassis just to see how it looks. The front springs are too long and the tires are only temporary but the height above the ground is as it should be, or at least that is how one truck sits that I was able to measure. Tires on it were 7:50 x 20's and the top of the fenders was 53" above the ground. Both are just about right in scale.