-

Posts

9,938 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

resin casting and molds

NOBLNG replied to Paul Payne's topic in Model Building Questions and Answers

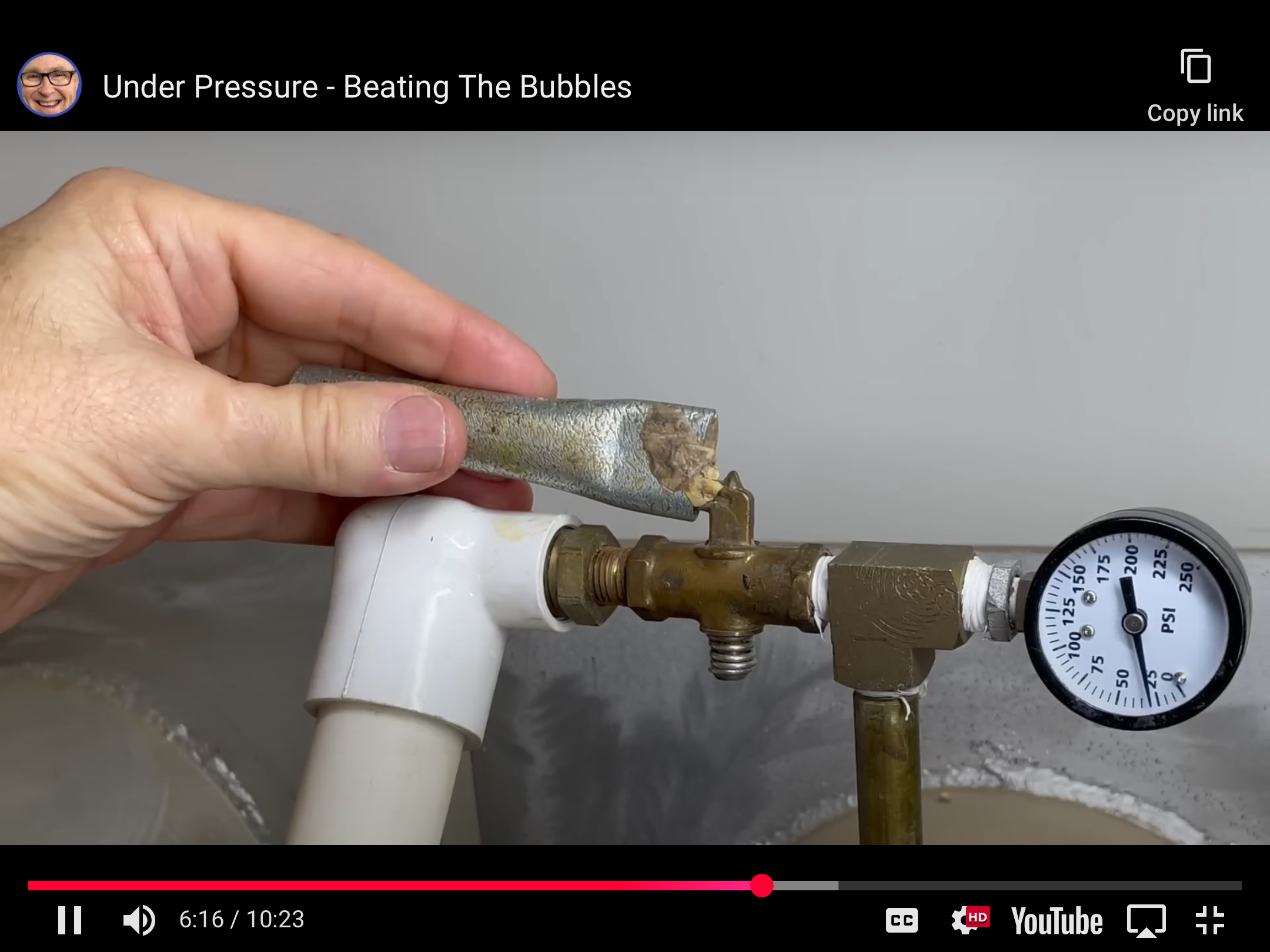

I have used about 60 psi for casting, but using relatively fresh resin. Those plastic fittings on his pressure pots are pretty scary looking! If they fail they can explode. -

You could try a shoe repair place for the eyelet, or maybe a sewing/fabric supplier?

- 5 replies

-

- entex

- dennis motor

-

(and 2 more)

Tagged with:

-

WARNING! Not all 1/25 scale is equal.

NOBLNG replied to WillyBilly's topic in Tips, Tricks, and Tutorials

Well they gave the blind deaf sculptor a photo of a corvette and told him what they wanted.🥴 -

1974 Econoline camper

NOBLNG replied to Repstock's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Fantastic looking start on that camper Tom!👍😎 -

Thanks Bil. Those were sitting on the bench so I grabbed them for a quick mockup. I don’t dislike them but I think big and littles might look better? Thanks Kevin. I WON that fight Len!!!😜 Thanks Steve. I wasn’t even planning to build this one…just decided to experiment with a roof stretch for giggles. But now I’m beginning to think it has potential?

-

You know…if people worked a little harder they might forget about their little aches and pains.

-

Nice work Alfred! Your bench looks kinda like mine. You guys are going to talk me into getting a 3D printer yet.😳

-

Fantastic upgrades Steve! I sure would like a little helper like Otis….but we want to do some travelling while we are still able to. Maybe in a few years.

- 187 replies

-

- 1

-

-

- plowboy

- roger hayes

-

(and 1 more)

Tagged with:

-

1st gen Bronco Leadsled Kustom?

NOBLNG replied to Impalow's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Awesome! Love your thought process.😎 That frame and suspension work is insane! -

Just having some fun with a flea market find.😜 Stock roof, luckily not glued to the body! With a 2-3/4” chop and 12-3/4” roof stretch. Lots and lots of filing/sanding later. Assessing the potential? Decided to slant the B pillars like Chevys and Plymouths.😳 I think I see potential now? Gotta work on that seam!😬 That blended better than I had hoped. Roof looks a little bulbous so it needs a pancake job. Eeewwww!😬 A bit of primer makes a huge difference. And finally…4-1/2” sectioned off the bottom of the body and hood sides. Rear fenders separated and lowered with the body. That’s it for now. 🤪

-

Who doesn't love a mock-up? Let's see yours!

NOBLNG replied to Belairconvertable's topic in WIP: Model Cars

-

Apart is not the state in which you find glue bombs at the flea market.

-

Corrected aesthetics are required to get some Palmer models presentable.

-

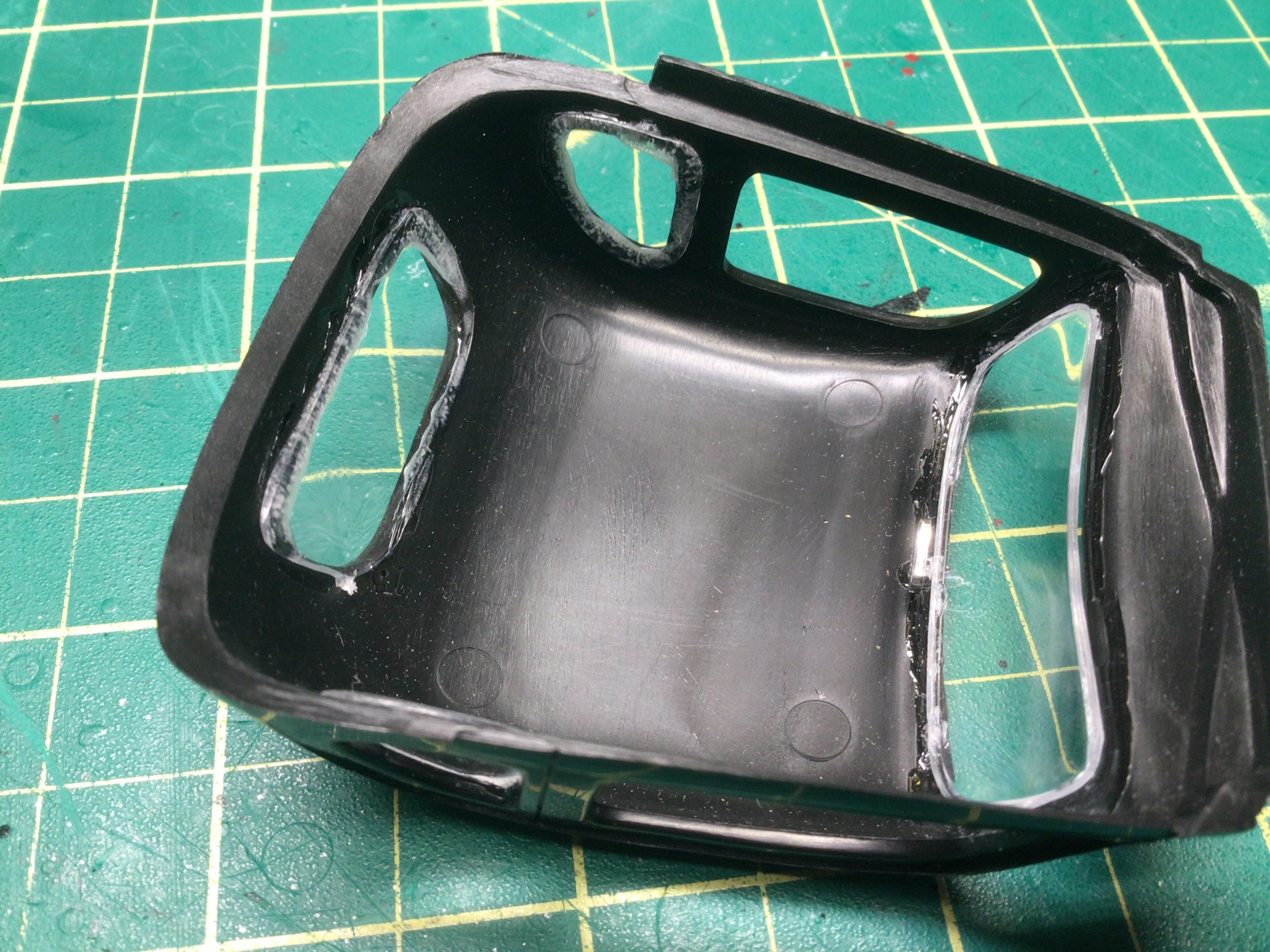

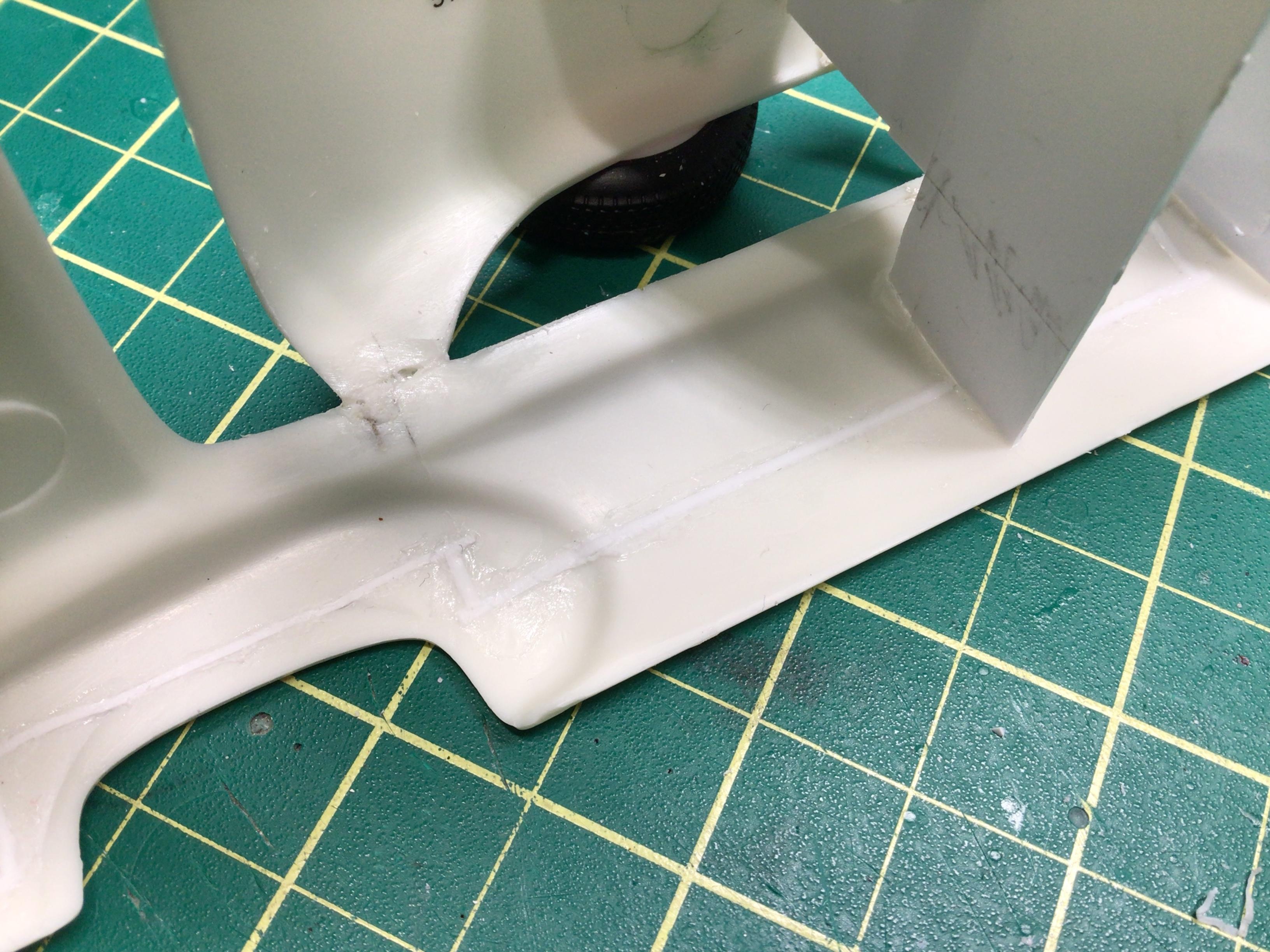

I gouged out the sectioning seams inside and out, then filled them with half round Evergreen and Tamiya extra thin cement. I made some new A pillars for it but still need to add some Milliput and shape them. When I lowered the entire roof it looked like it had a real rake to it, so I raised the front back to stock height.🙄

-

No putty on the section seam yet. It will take a skim coat in a few spots…mostly because the two panels weren’t exactly level.

- 17 replies

-

- 6

-

-

- sectioning

- gouging

-

(and 1 more)

Tagged with:

-

resin casting and molds

NOBLNG replied to Paul Payne's topic in Model Building Questions and Answers

Thanks for this info and the link to your site Rob. Vacuum degassing makes a huge improvement on the mold quality indeed. I have cast the parts themselves under pressure but not vacuum. Have you tried both or know if vacuum is better than pressure? Thanks, Greg. -

It’s all looking very nice Dave! I would love to build the transport trailer, but I have nowhere to display something that big.

-

Nice work so far. My models don’t need to roll so I would just replace that pin with a styrene rod and glue the wheels solid. Don’t know if that matters to you? They would still steer.

-

It looks great Allison!😎 They are cute little cars. Is there an engine in it?…pics? I have a Toyota S800 I’m working on.

-

Exhaust is now finished and made some links for the rear axle. I also got a fuel tank made and added an inset filler cap.

-

Believe me I know what you mean. 😬 On my ‘41 Plymouth I used a thick layer of Sprue Goo underneath and softened the entire top surface of the front fenders. This is much more localized.

- 17 replies

-

- 1

-

-

- sectioning

- gouging

-

(and 1 more)

Tagged with:

-

You venture outside the norms quite a bit I imagine.

-

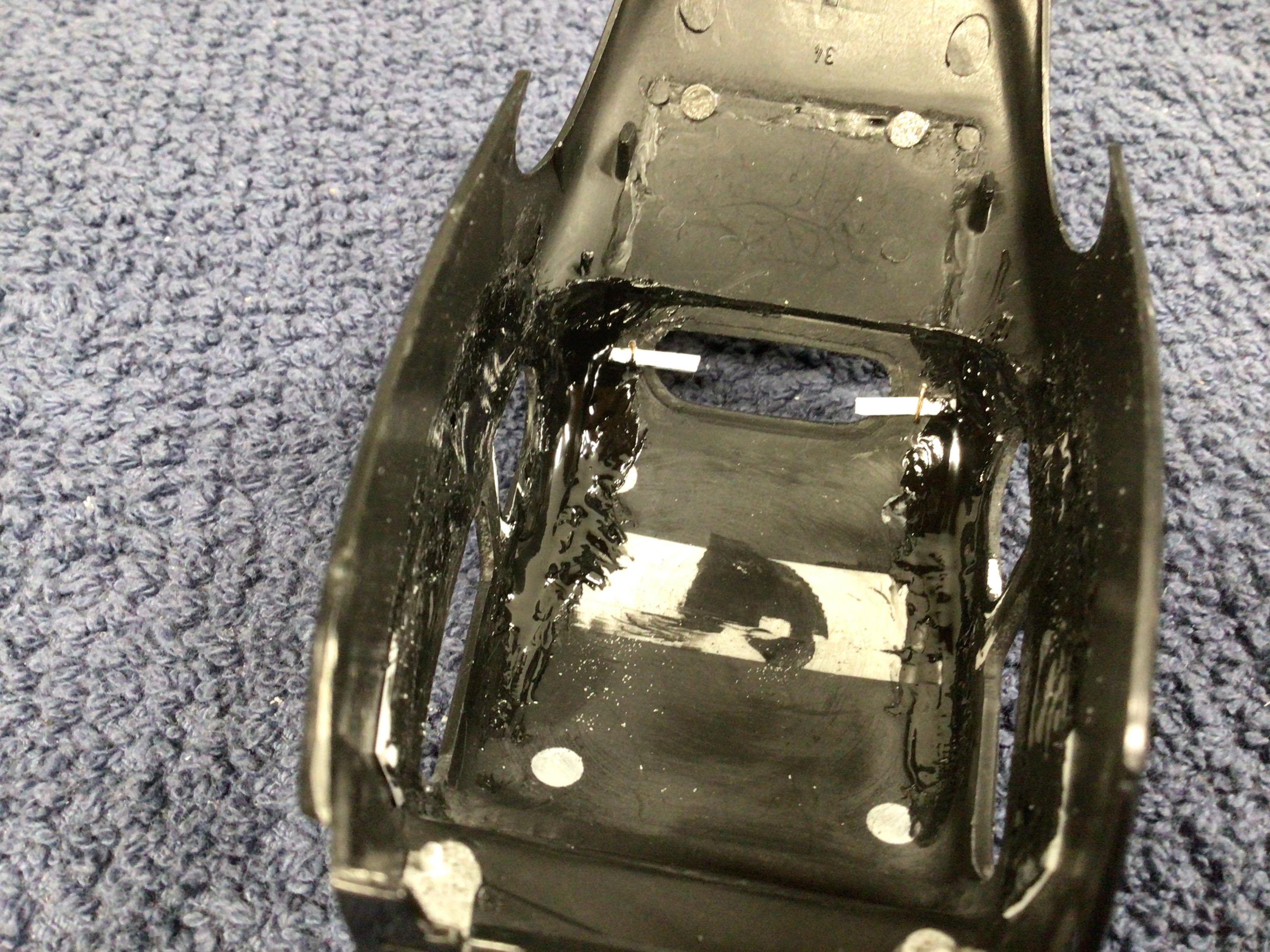

I am sectioning a ‘51 Chevy. I got the panels tacked back in place with Tamiya solvent and bits of styrene and CA. Due to a poor cut, I have a fairly large gap in spots. I’m not fond of the idea of filling the cracks with CA or putty. For access to the interior joint, I made this little scraper from 1/16” stainless tig rod and chucked it in my pin vise. I also made one 90 degrees to this one for the vertical seams. After gouging out the seam I glued in some 1/16 Evergreen half round with copious amounts of Tamiya thin cement and smushed it into the trough. When it’s good and dry I will do the same to the exterior. On the exterior, I can use the butt end of a drill bit. Some places I can get away with nothing or .020” round for filler and some I need .060” half round.😳

- 17 replies

-

- 6

-

-

-

- sectioning

- gouging

-

(and 1 more)

Tagged with: