-

Posts

10,231 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

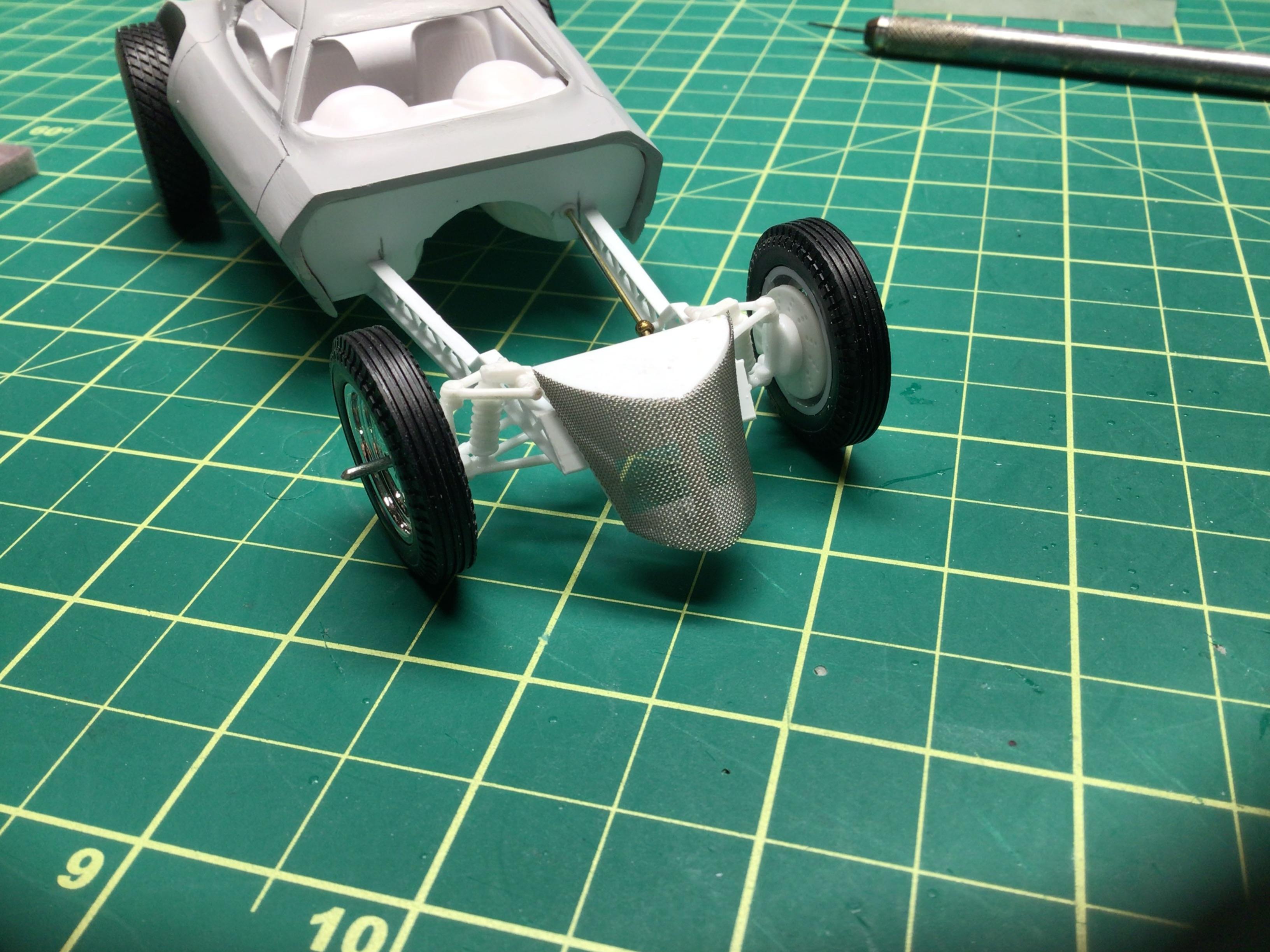

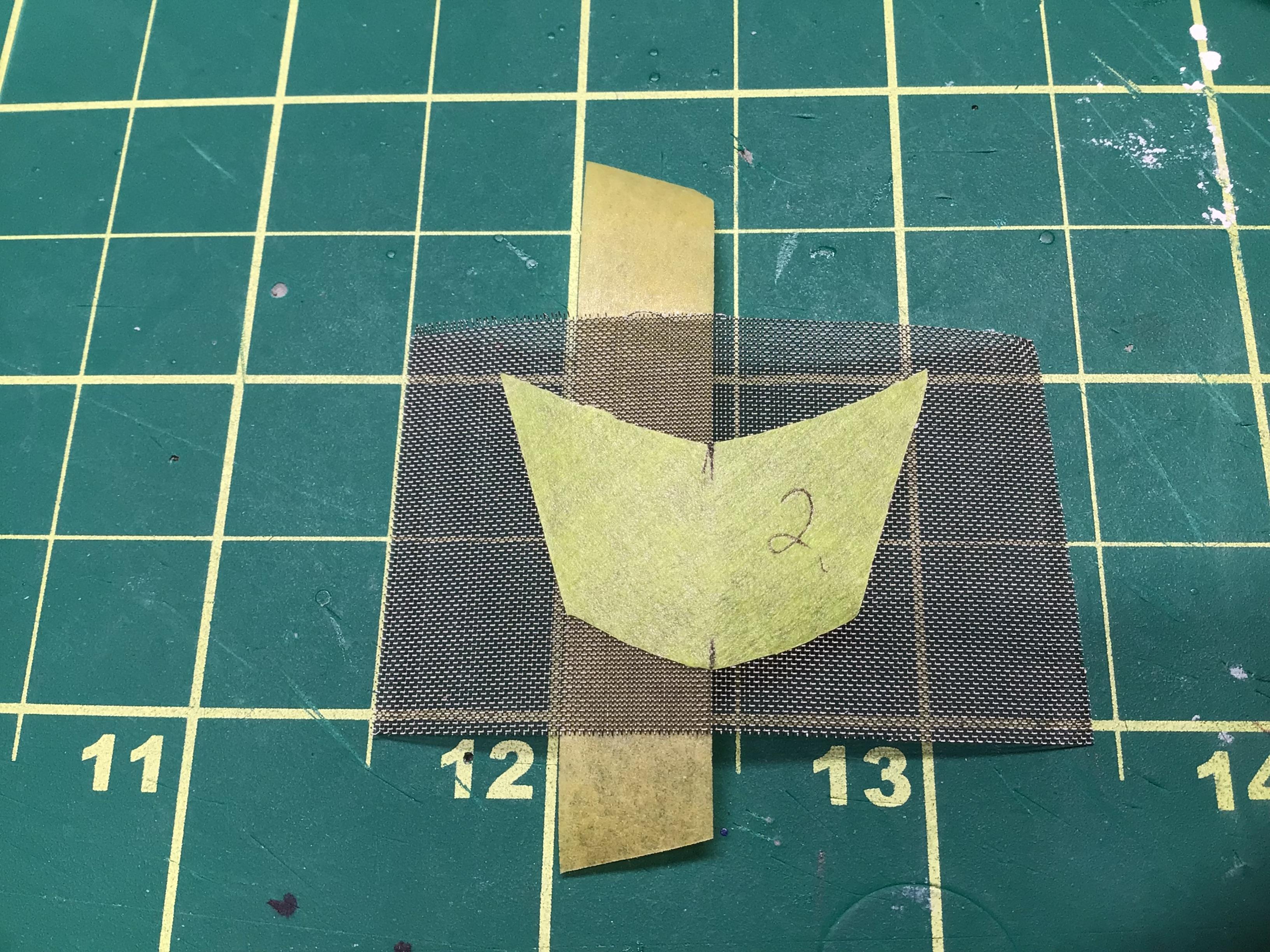

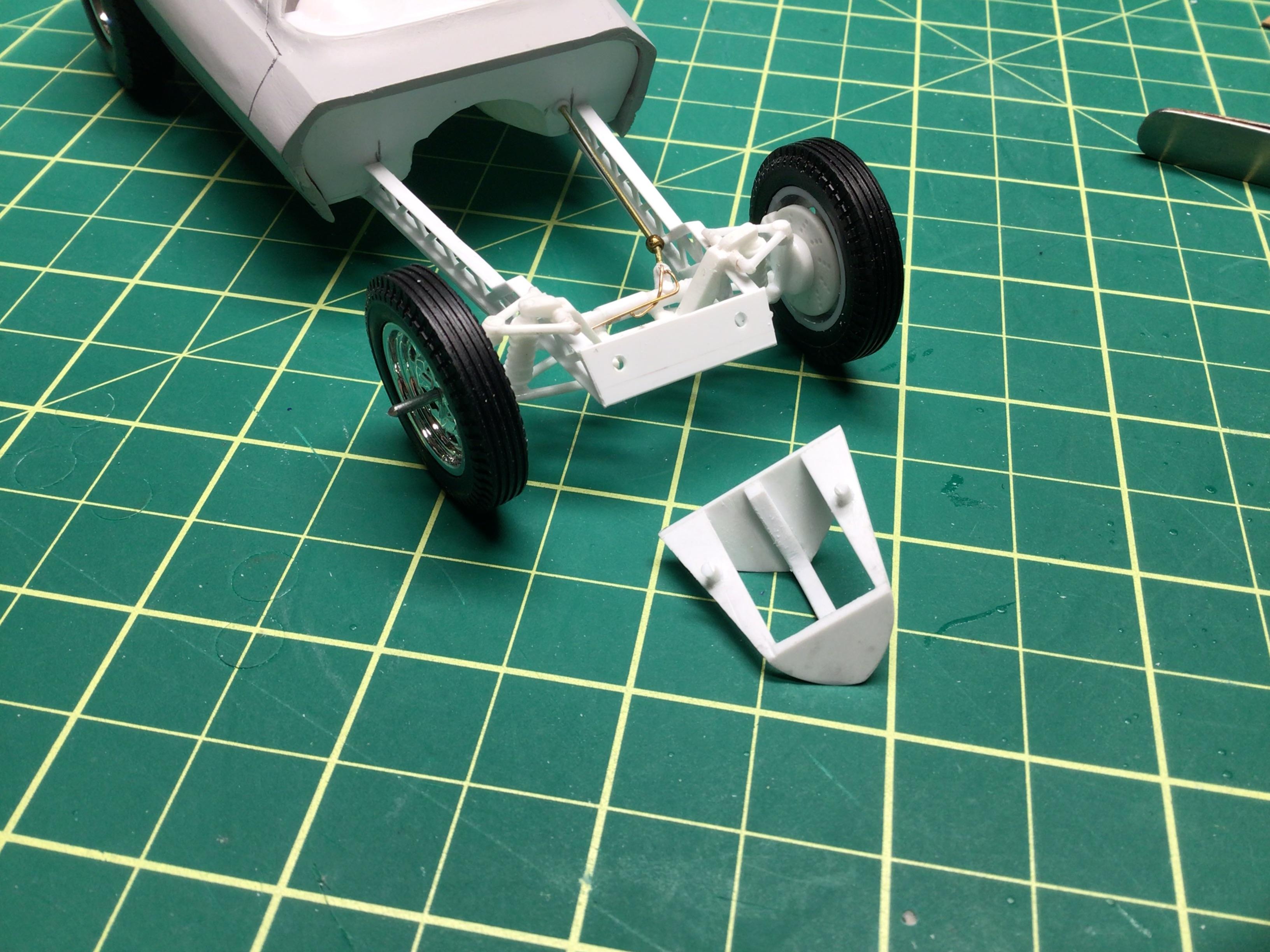

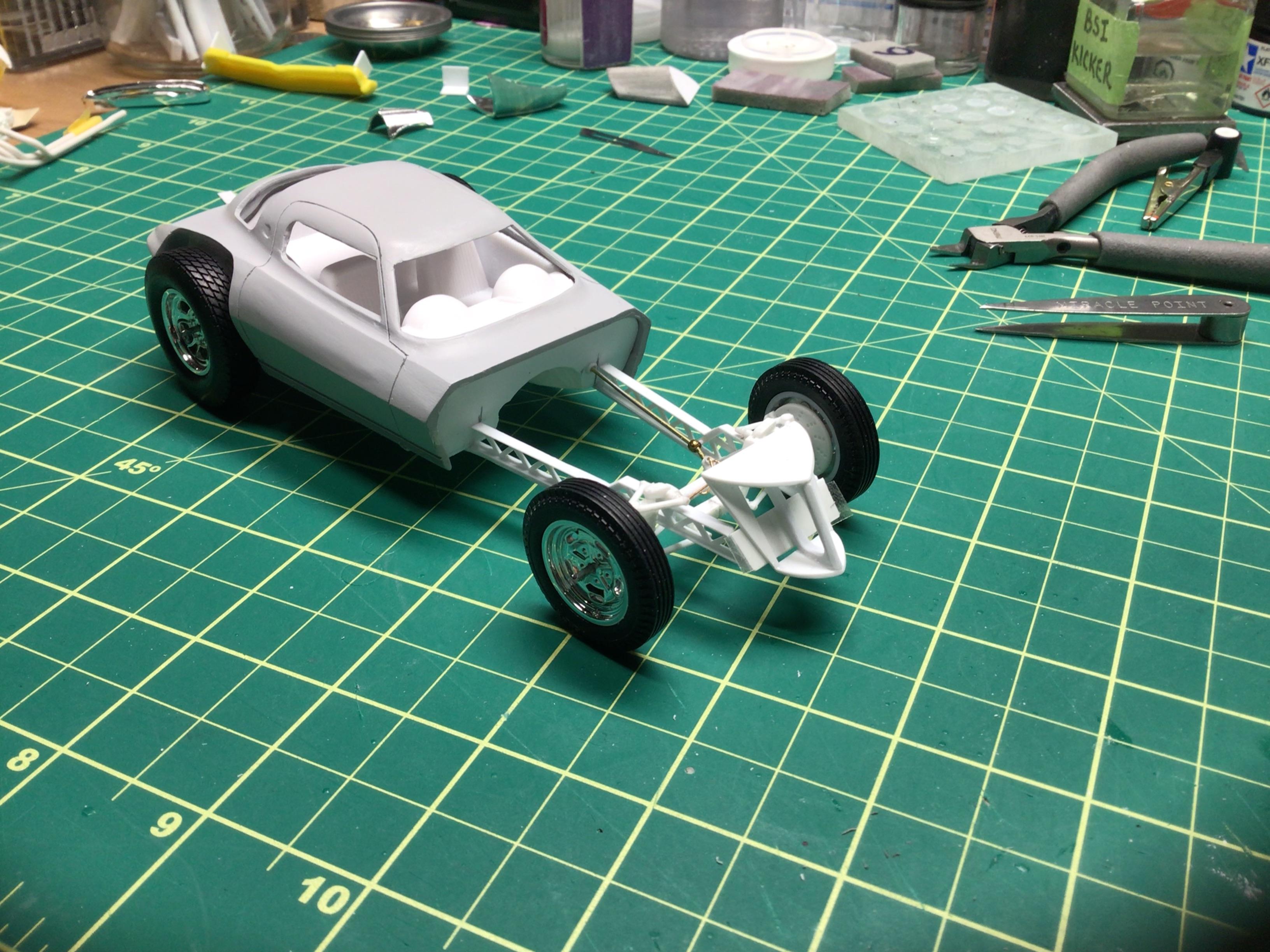

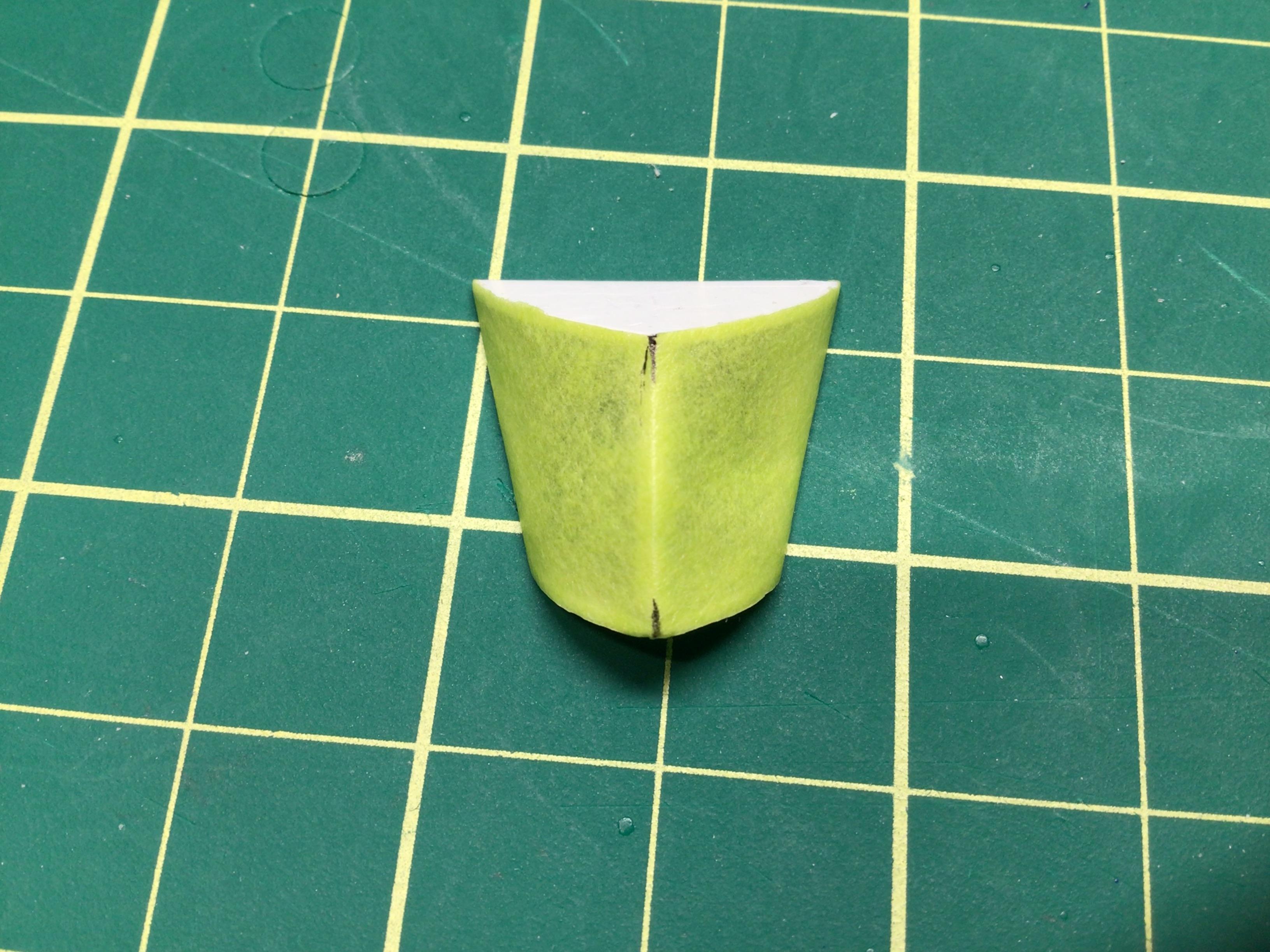

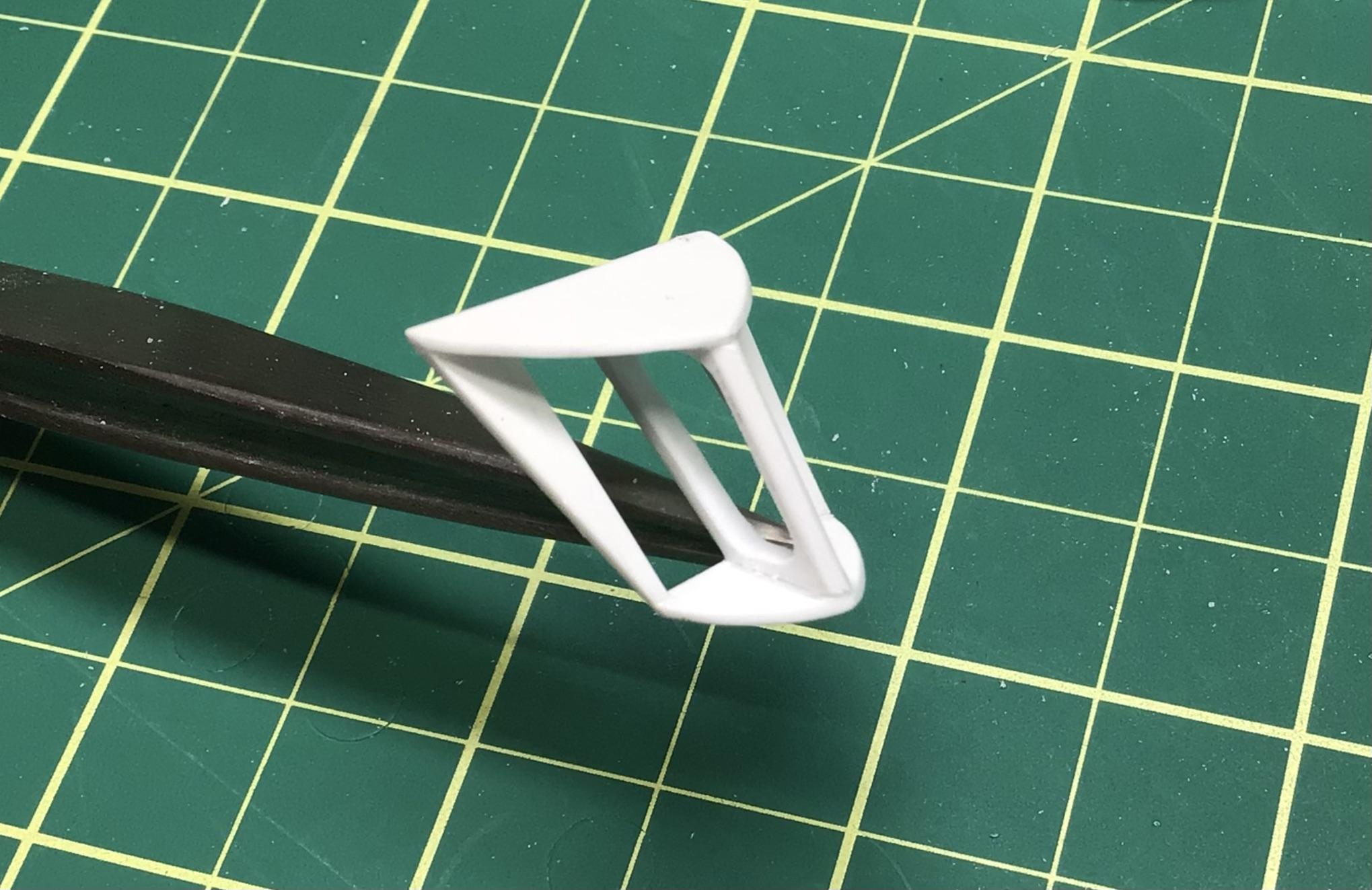

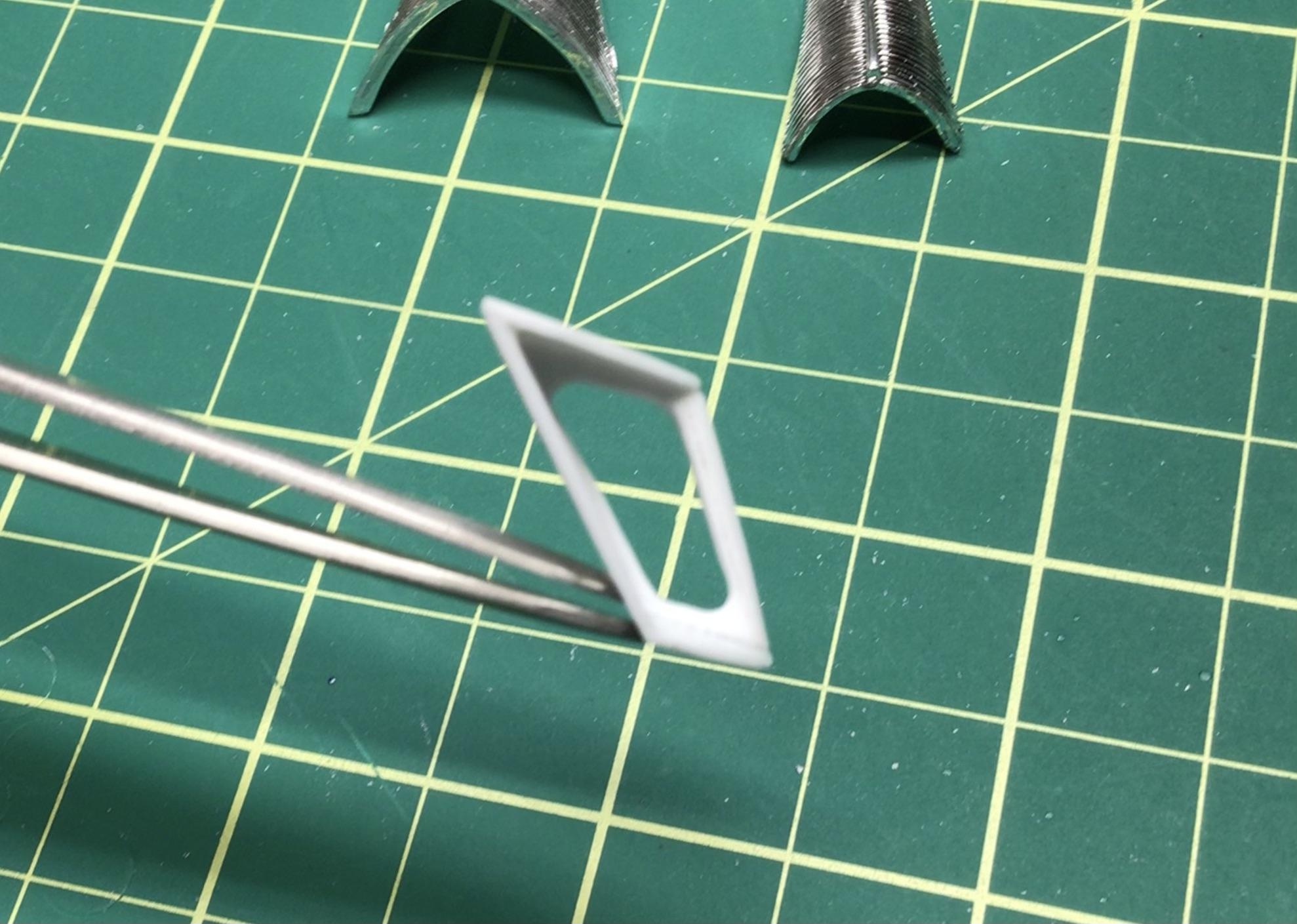

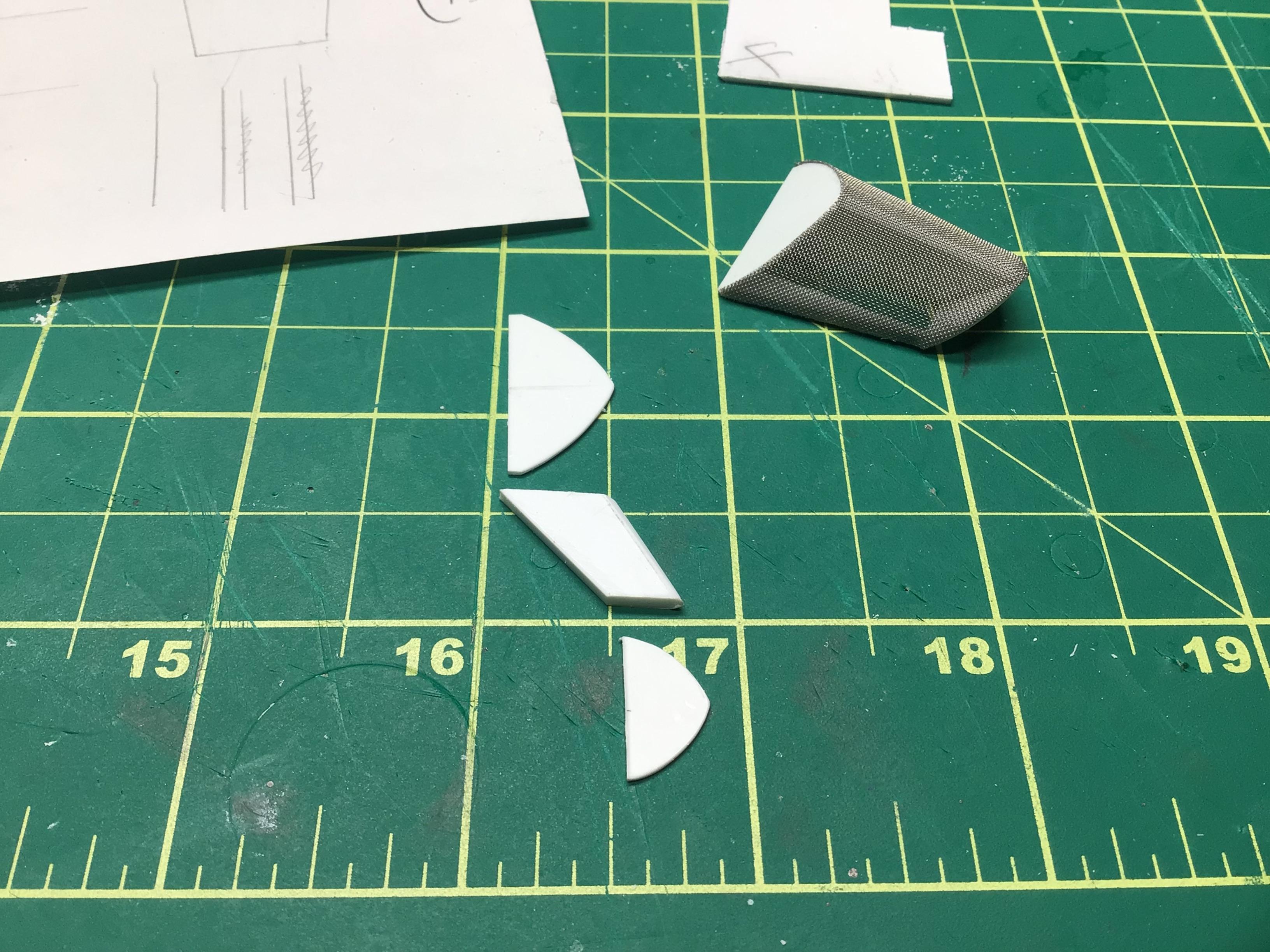

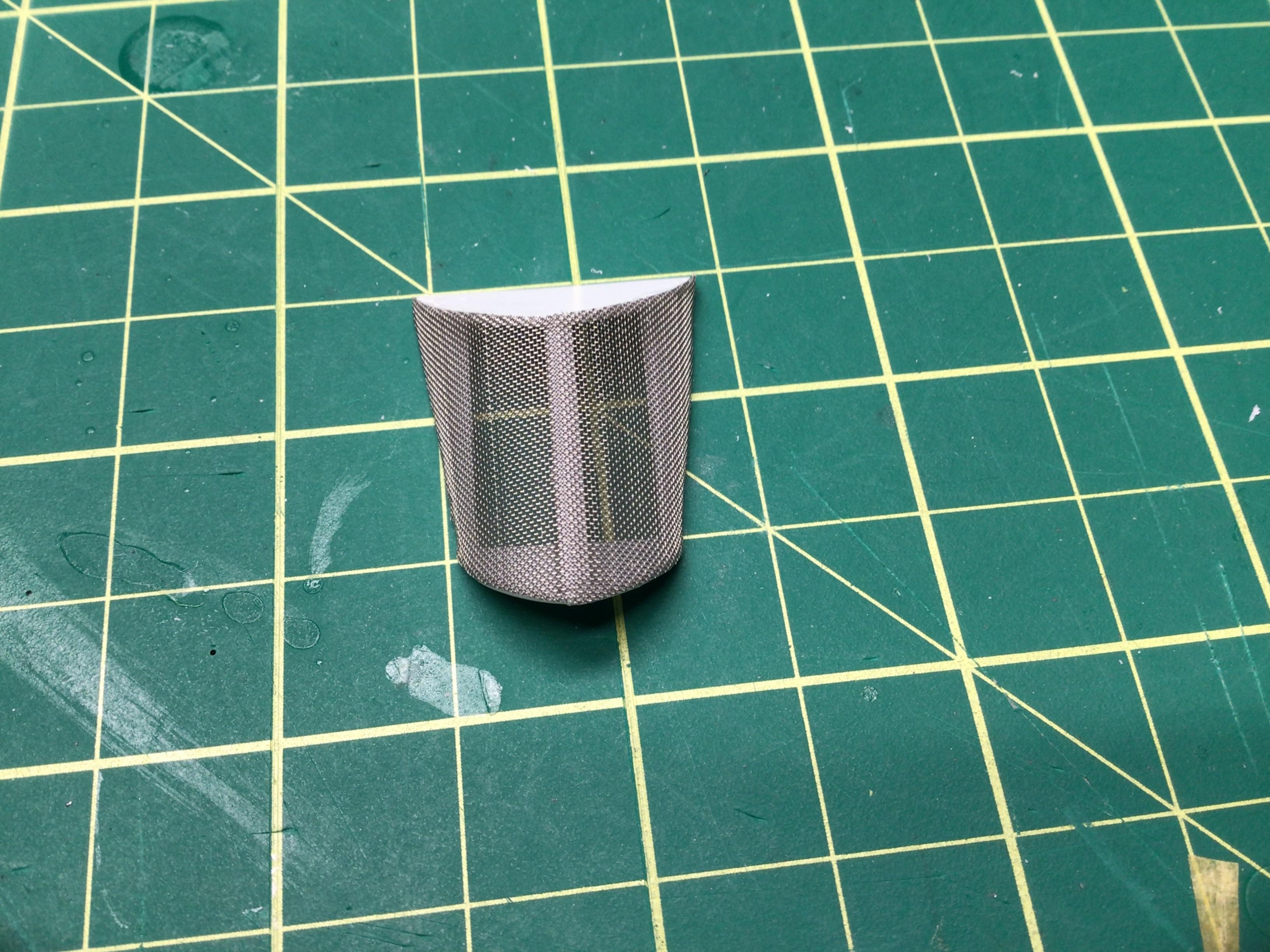

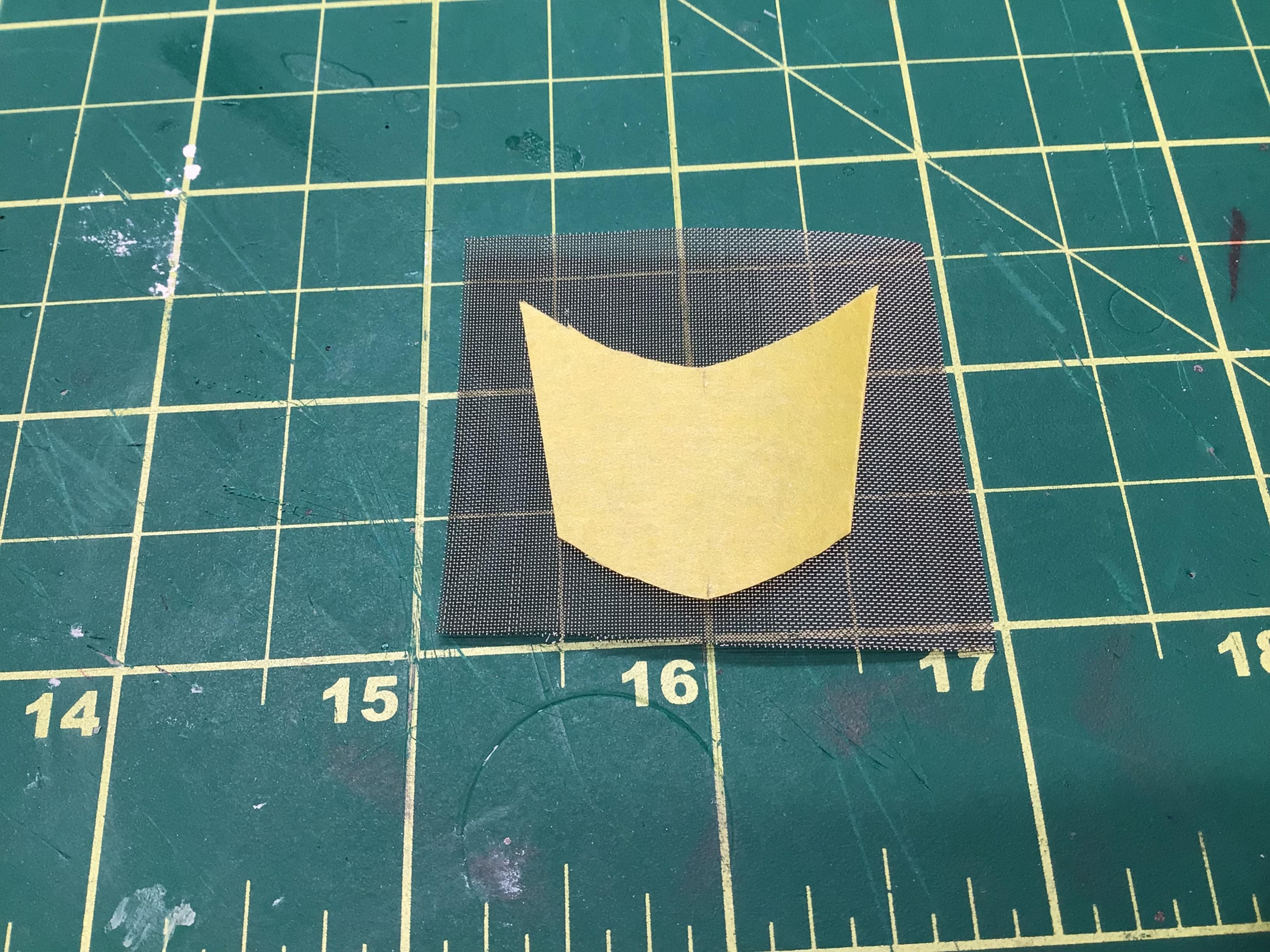

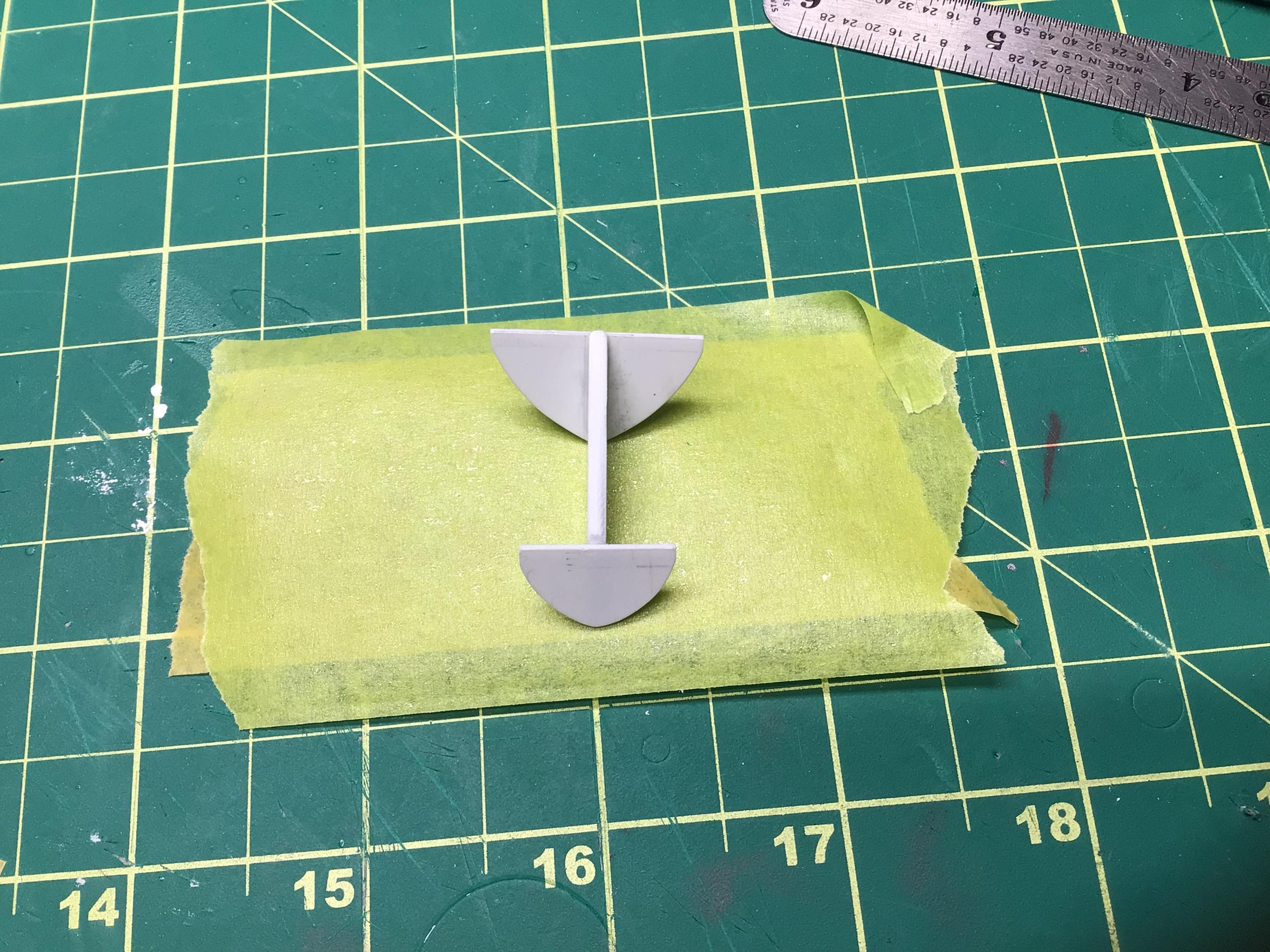

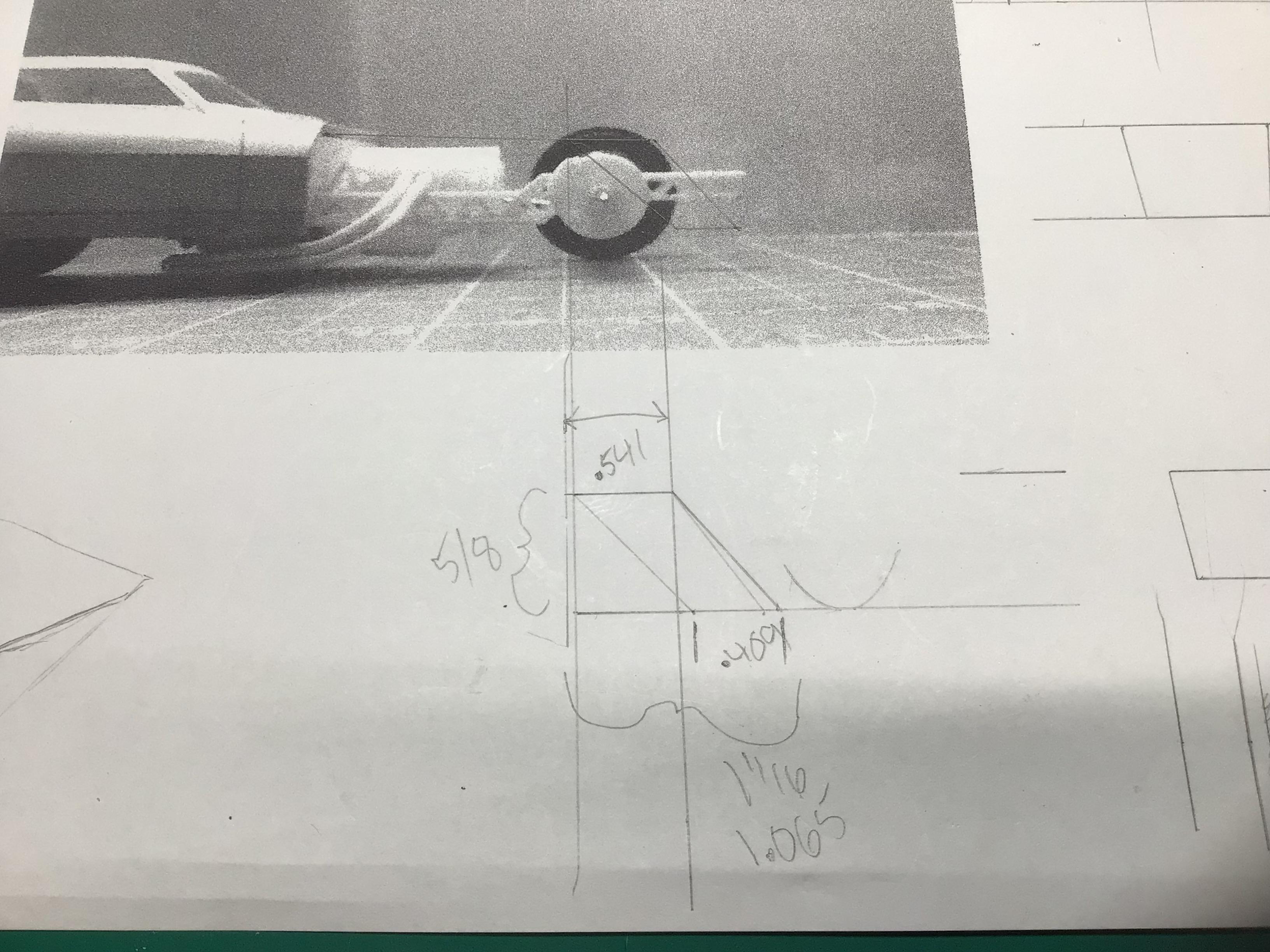

I finally had an idea how to go about making a grill for this thing. I started by drawing a profile of the rake I wanted. Then cut three pieces of styrene to shape and glued them together. I used a method of layout affectionately known in the hvac trade as “rollation” to make a pattern for the screen. This first attempt worked perfectly, and I would have used it except that it proved to be too tall to look good. So I made a second, shorter one. I traced the grills from a ‘37 and ‘40 ford to get the upper and lower shapes. I considered just chopping the bottom off of the’37 grill and using it, but I was worried that it would still be recognizable as a vintage ford grill.🤔 I trimmed the frame rails back as far as possible and capped them with a piece of .030” Evergreen, then used some double faced tape to locate the framework where I wanted. Then drilled and pinned it . I put a strip of tape on the inside of the screen in line with the mesh to make it easier to align my pattern. After creasing the centerline, I just rolled each side around a hobby knife to get the curve approximately. I may put some small trim of some sort over the outer perimeter of the screen yet? I’ll have to make some headlight mounting brackets to mask the ends of the frame rails that are protruding…or I might make yet another grill that stays the same width as the frame rails?🤔 I can now begin building a radiator to mount on the backside and also a hood. I made a rough cardboard pattern, but need to make something with some shape and contouring to it. Thanks for lookin’.🙂

-

Face it Jim…the squirrels OWN US! They decide what get worked on and when.😳

-

Singing is not what I would call what is being recorded by some bands.

-

I love this kind of stuff!😎 Your work is very methodical and well thought out. It is amazing how subtle changes like the belt line section that most people (me included) might not notice on the finished model unless it is pointed out, can improve the aesthetics of a vehicle. Thank you Jon for documenting not just what you did, but and how and why you’re doing it.👍😎

-

cheetah reboot

NOBLNG replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Yes, glad to hear you are Ok, and back on this utterly amazing build.👍😎 -

Subtle yet distinct changes that give the model a sleeker look than the original. Yet the changes retain the character of the car. Well done!👍😎

-

Today, if you can believe it, may be known in the future as “the good old days”.

-

I really like that T-bucket and the’30 coupe. I would have to give it to the ‘30 coupe though, as it is more detailed…ie: brake lines etc.

-

Who doesn't love a mock-up? Let's see yours!

NOBLNG replied to Belairconvertable's topic in WIP: Model Cars

-

Really great looking rat rod there Derrick!👍 I like the artillery wheels and that power plant is awesome!😎

-

Beings of the extra-terrestrial type better show up soon as I am getting tired of waiting.

-

I haven't been around since Monday night. Here's what happened

NOBLNG replied to Can-Con's topic in The Off-Topic Lounge

Wow, that’s fairly quick service. I wish you all the best going forward Steve. -

K&R Kustoms+Rods '34 5ive Window Chopped Coupe

NOBLNG replied to Kit Karson's topic in WIP: Model Cars

I say without too.😎 -

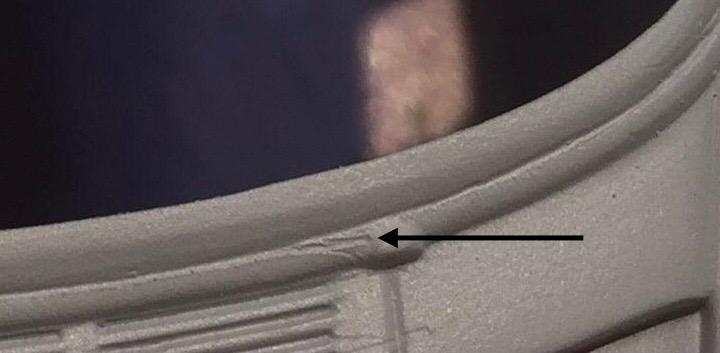

I don’t think it’s necessary. There is lots of material on both ends that can be sanded away.

-

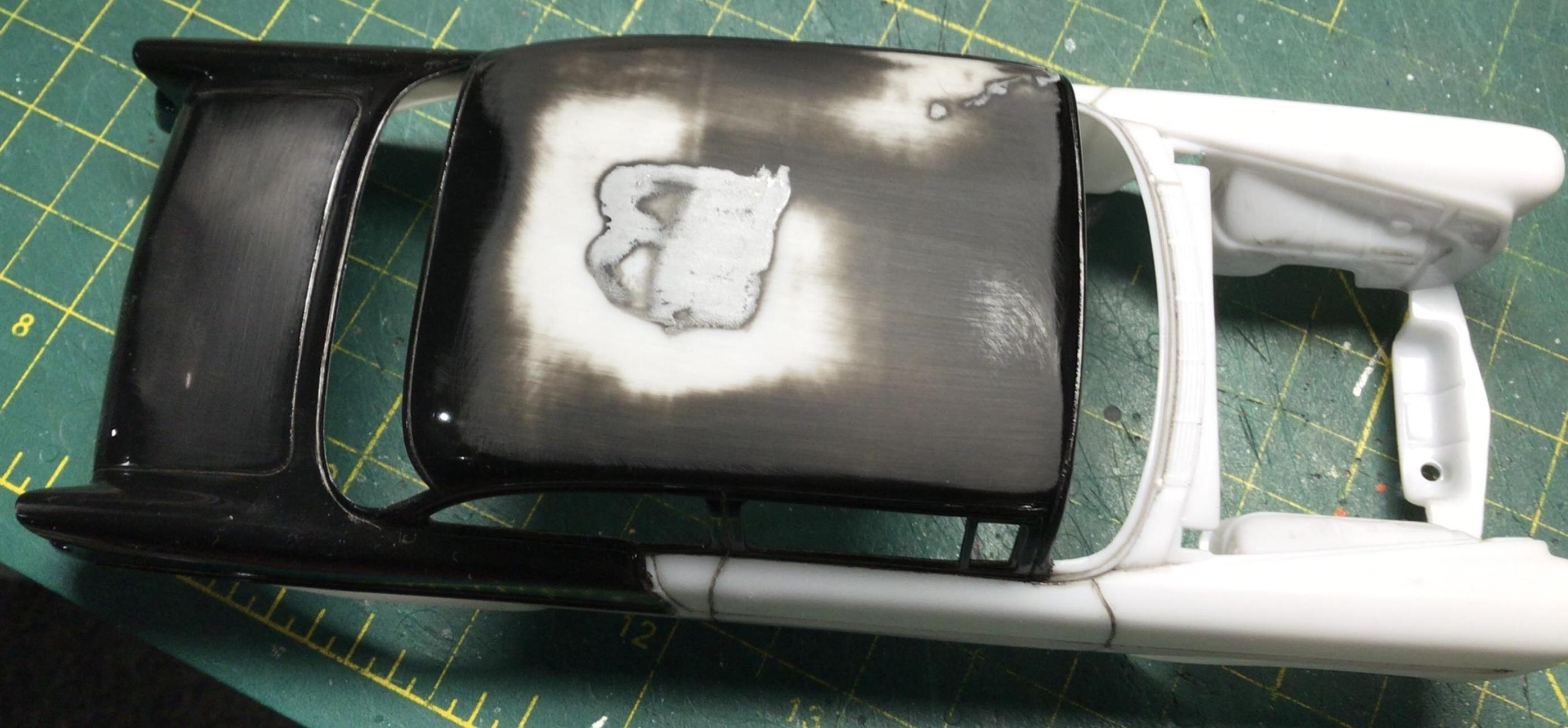

I had a lot of that ghosting on my roof too…plus a sink mark directly above the interior light if I recall. The project is still in primer so I don’t know if the issue is 100% solved.

-

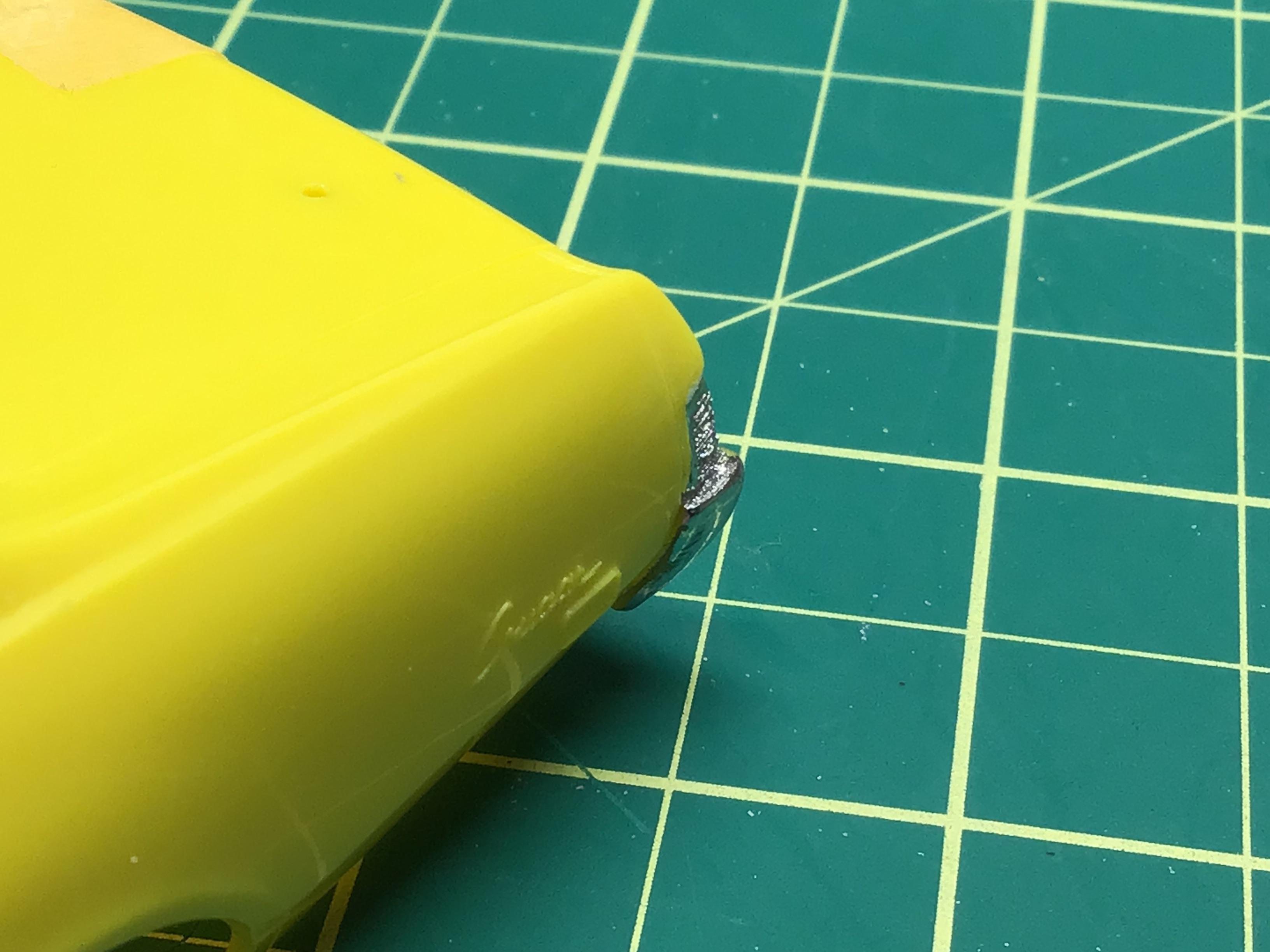

Ok, I filed and sanded the backup lights down till they were flush with the outer side of the body. I went a little too far and had to add back some on the passenger side so that’s why the styrene is white.😬 One thing I do like about yellow plastic is that the carpet monster has a hard time digesting tiny parts.🙂 I cut a short chunk off of one of my Tamiya photo etch saw blades and used it as a corrugated scraper to get the definition lines back in…not perfect but better than smooth. On the front end, I cut the top edge of the grill off and added it to the hood where it belongs, and am in the process of getting the grill and bumper to fit nicely. I also widened the front air dam. That’s all for now folks. 🙂

-

Yeah, or give the entire bumper a coat.

-

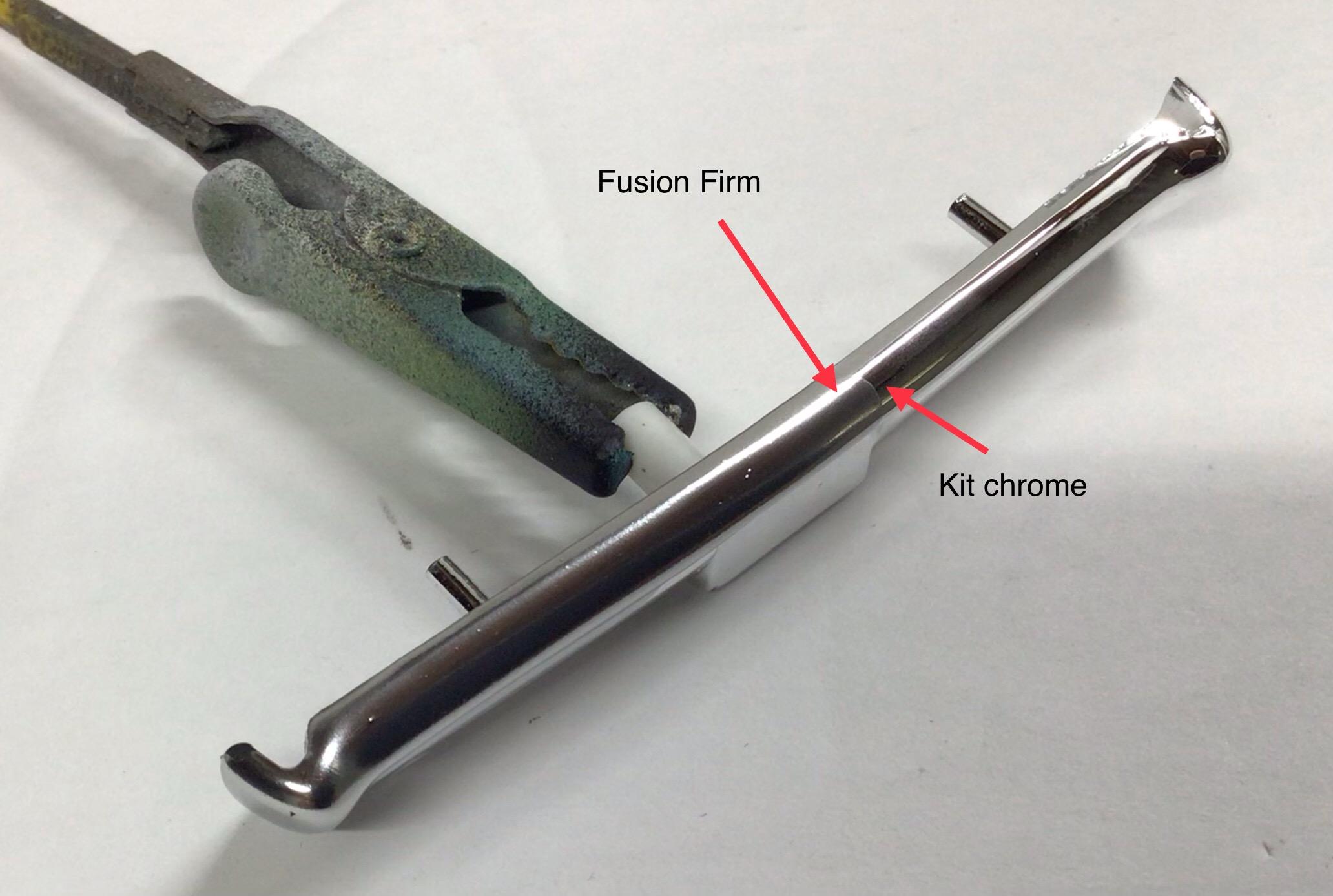

This is nice stuff! I did a test on a spare bumper just to see how it blends with kit chrome for repairs. I sanded off some of the original chrome: Then brushed on some FF:

-

Maybe you could drill and pin the part for extra strength?

-

Both paint jobs look superb!😎

-

-

“Bite me!” is a good come back for a perceived insult.