-

Posts

486 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Rick L

-

Unfortunately, you don’t know what quality you’re going to get when ordering printed parts. Some vendors print out parts with high resolution, resulting in a clean soother finish, or step up the speed of production with low resolution, producing poor results. Low res is useless for detailed parts because you’re going to lose the detail from filling and sanding. Low res is only good for plain surfaces and still it’s a lot of work to fill. To answer your question, I have found Evercoat polyester glazing putty to work best for this application because it doesn’t shrink like other brands. May I suggest to anyone looking to purchase printed parts to check with the forums view on the merchants products. Or give a shout-out to the better vendors.

-

Hey Snake I for one miss your input. As a matter of fact the whole gang here on the forum wish you a happy and speedy recovery. The vote was 467 to 3. ?

-

Agree with Ace. It may also help to sand the mating side of the styrene with a coarse grit sandpaper.

-

Making seats look like leather...

Rick L replied to Hillbilly Deluxe's topic in Tips, Tricks, and Tutorials

Spot on Steve. I’m also impressed with the interior door handles. What was your source? -

I agree with with Steve and would emphasize not to skip on the primer. Light grey primer will bring out any flaws the body has before you paint. It’s better to sand out the flaws now than after you lay on the black.

-

Maybe get around it by ordering DA through Amazon? Although isopropyl is the closest option, it is not the same.

- 13 replies

-

- 1

-

-

- california

- bans

-

(and 1 more)

Tagged with:

-

-

What ever the technique chosen, A little trial and error would be in store. I agree with Doug’s original idea in that the bb’s would make a smooth dent. The Dremel bit would be on the rough side.

-

Heat the bb’s instead of the plastic. Then pour the bb’s over the cold plastic.

-

Bobby Rydell’s never heard of you either.

-

Back in 60’s Bobby Rydell had 34 top 100 hits with a net worth of over ten million when he died. If you were old enough you would know who he was.

-

Bobby Rydell also passed away.

-

Radio antennas another dollar store money saver.

Rick L replied to Mike C.'s topic in Tips, Tricks, and Tutorials

Ok I’ve got the pliers. Where is my cat anyway? -

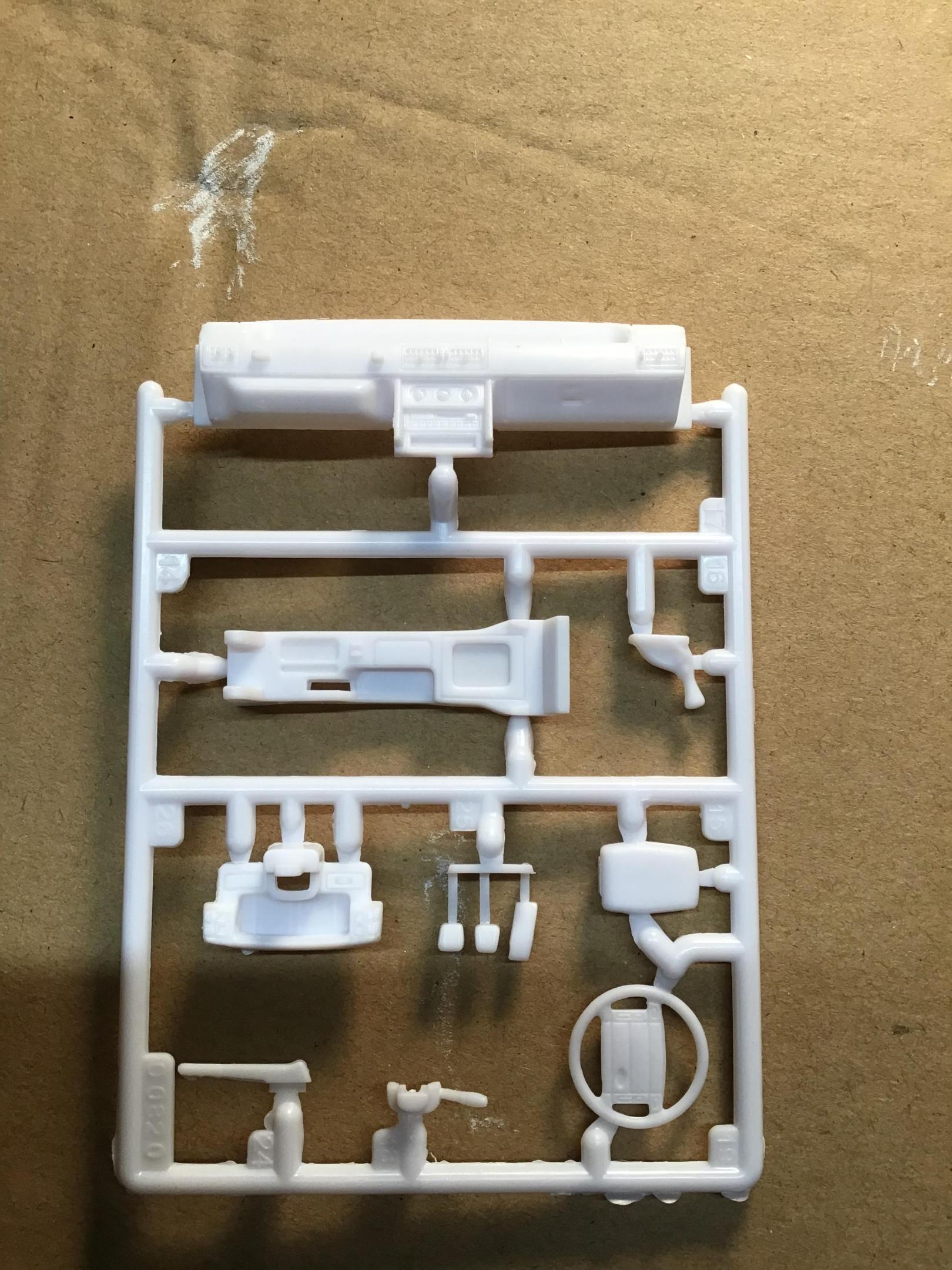

Anyone doing any projects in 3D-printed plastic?

Rick L replied to ibj40's topic in Tips, Tricks, and Tutorials

CA will work as a filler but large quantities can be nasty to breathe. Be sure you’re well ventilated. Another application available by Smooth-On is XTC-3D, specifically made for that purpose. -

? Our best lessons are from our mistakes. The dry brush technique works very well. Start with a light base color and work darker shades each layer. Making sure each layer of paint is dry before laying on the next works best for me. It gives the grain more definition.

-

Airbrushing: Jumping in with both feet and my wallet.

Rick L replied to Bills72sj's topic in Tips, Tricks, and Tutorials

If you put your finger over the nozzle and push the button you will cause the air to back flush through the bowl. In the trade I painted with a more advanced DeVilbis suction feed gun. After removing the needle a few times, the packing would get loose and the paint would flutter, not bubble. Tightening the packing nut would relieve that problem. In the hobby I use a Grex and I agree with using airbrush lubricant only.- 72 replies

-

- airbrushing

- supplies

-

(and 1 more)

Tagged with:

-

Airbrushing: Jumping in with both feet and my wallet.

Rick L replied to Bills72sj's topic in Tips, Tricks, and Tutorials

The probable cause of bubbles in the cup may be a blockage in the nozzle. That blockage could be caused by leaving the paint in the gun idle too long without running a little thinner through. I’m not saying this IS the problem but if it is, your going to have the same problem with your real airbrush.- 72 replies

-

- airbrushing

- supplies

-

(and 1 more)

Tagged with:

-

Welcome Jarred to eliminate the orange peel try heating the paint can in hot tap water before spraying. Do three coats. First, a light mist coat. Second, a medium coat and last a wet coat. Be patient between coats. Be sure each coat is dry before spraying the next. I like the stance by the way.

-

1979 and priced at 72.9 per gallon. Yikes!!!

-

Gluing Rearview Mirror on Windshield

Rick L replied to TransAmMike's topic in Model Building Questions and Answers

I would put a tiny drop of CA where you want the mirror located on the windshield. Grab the mirror with a pair of tweezers, dab the base of the mirror with a tiny bit of accelerator and place the mirror on. Be careful this is a one shot deal. Being experienced you know it’s going to kick the minute the two components touch. Obviously the smallest amount you use the better it will look.