-

Posts

486 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Rick L

-

Thanks Pete. Much appreciated.

-

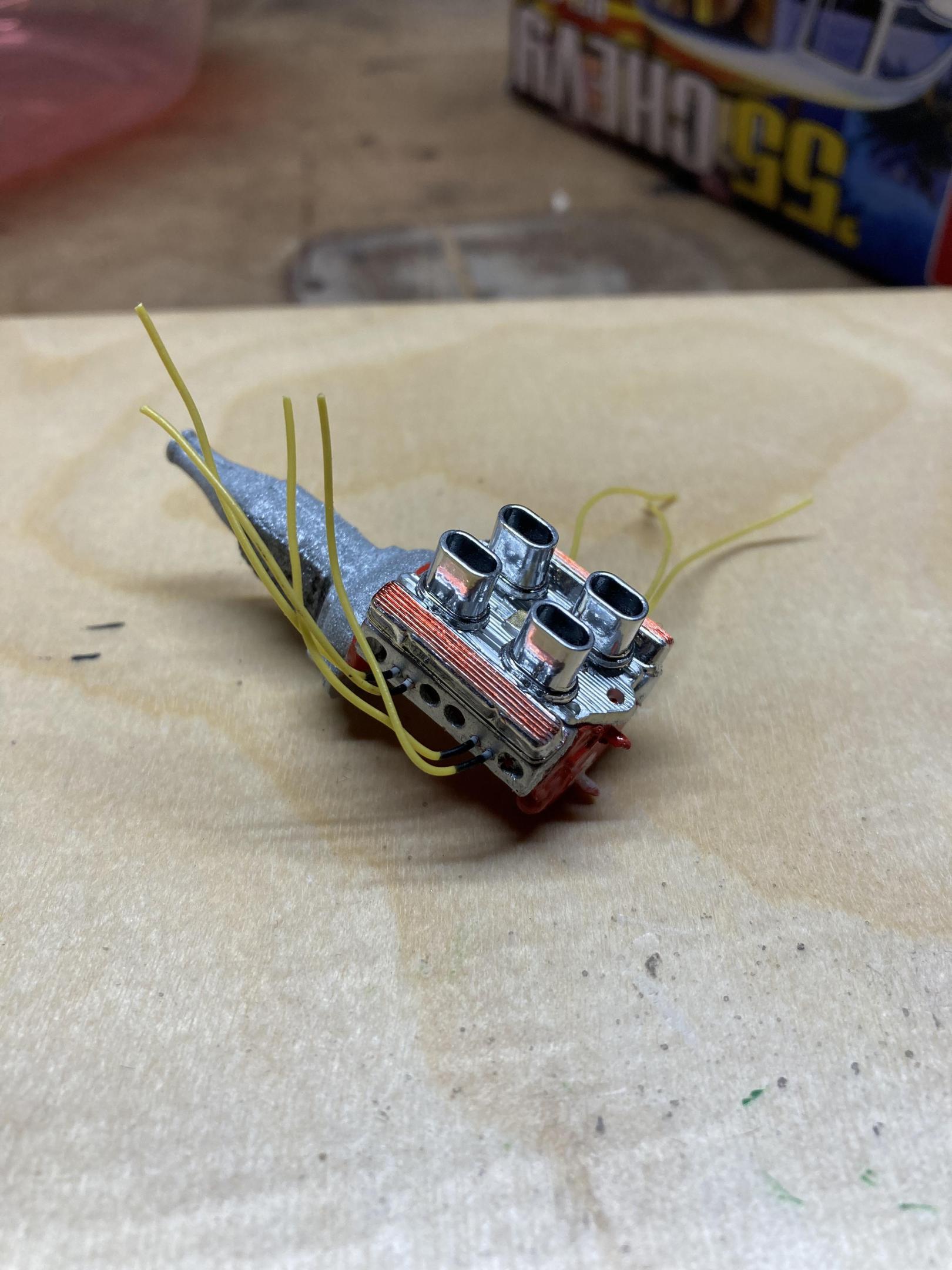

I found this on ebay. It measures .02 dia. which would be 1/2 in real scale but I don’t think it’s too glaring on the model.

-

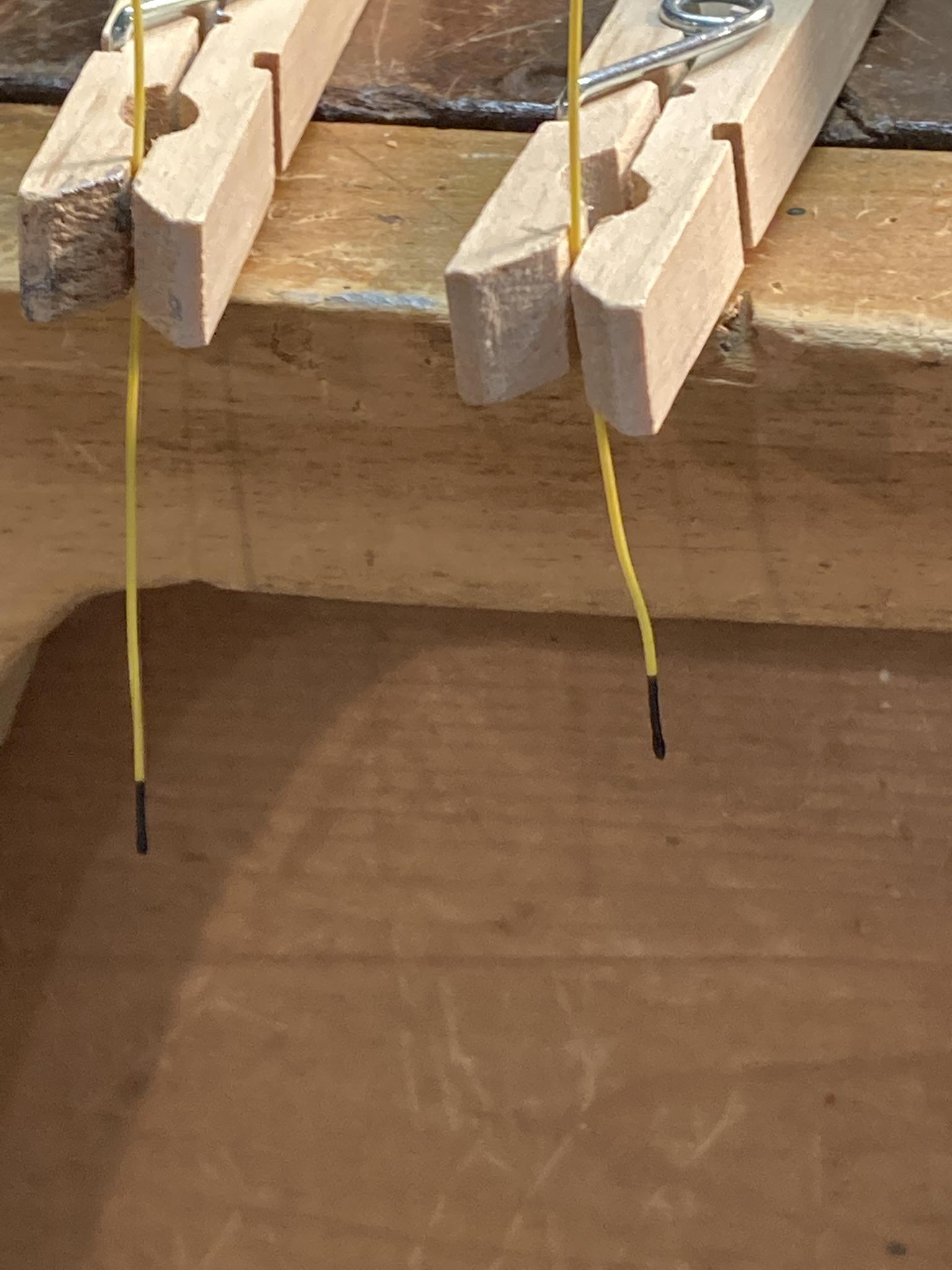

Thought I’d try something different to get a spark plug and wire setup. I first dipped the wire into a bottle of flat black lacquer. You can add thickness by adding multiple dips after the previous coat dries. The next step was a dip in gloss white lacquer making sure the black exposed were all the same length. Next I drilled out the heads and pushed the wire through making sure the white exposed was the same length. Then bent the wire inside the head over, added a drop of CA and a quick spray of water to kick it quickly. I used lacquer paint because it can hold up to a little bend when I install the wires into the distributor.

-

I line my paint booth with a Boston Sunday Globe I bought back in 2005 for a couple of bucks. Still have plenty of pages left.

-

Part ID - 1/12 '57 Chevy

Rick L replied to Maindrian Pace's topic in Model Building Questions and Answers

I agree withJames. They’re made for constantly open hood display. -

Part ID - 1/12 '57 Chevy

Rick L replied to Maindrian Pace's topic in Model Building Questions and Answers

What kit is it from? -

Type site:modelcarsmag.com embossing Into your search engine and it will give you extensive reading on the subject.

-

If anyone is interested, there’s a huge model railroad auction at Trudels auction house in Bellingham Ma. Saturday 02/18/23. They claim over $250,000 value. You can check out items on Trudels website.

-

You got a great deal! I had used flocking to recreate a scale model of a 70’s conversion van a friend of mine owned. He had shag rug from walls to ceiling. It was a perfect match. To recreate a tuxedo carpet however, you may have better luck with embossing powder.

-

Why the orange peel disaster?

Rick L replied to Sidney Schwartz's topic in Model Building Questions and Answers

Is the green enamel and the clear lacquer by chance? -

That is a good question Joe. If painting lacquer You can wait until you are finished with the paint job if your steps are 15 minutes apart. Then you can break down the gun and clean it thoroughly. If longer than 15 minutes I’d run a little lacquer thinner through between steps.

-

I did the the same thing on this AMT 55 Chevy. A little Tamiya putty and flat black spray. Close enough.

-

So there we have it guys. Size doesn’t matter after all.

-

Don’t be discouraged. The process is simple. Go online and check out the tutorials. You can buy a small kit and experiment on a junk part.

-

As I had mentioned before, Smooth-On has informative info for the novice. The four part mold was thrown in to show the potential.

-

-

Be forewarned that clays with sulfur and masking tape will inhibit silicon mold rubber. A tutorial from Smooth-On will help you along the way.

-

How big is your... stash?

Rick L replied to Pierre Rivard's topic in Model Building Questions and Answers

I agree. It’s funny how the mind works. I can tell you about models I built 60+ years ago but I couldn’t tell you what I had for lunch yesterday. -

How big is your... stash?

Rick L replied to Pierre Rivard's topic in Model Building Questions and Answers

I’m not sure if having enough model kits is some sort of therapy or the reason that we may need it.? -

That is one sweet looking Corvair.

-

I have seen model kits at the Woonsocket store but few and far between.

-

The corrugated look is the hard part. The rest would be easy. Nice catch Steve.

-

You gotta lot of stuff under that hood. Well done Steve.

-

Excellent idea to use the inexpensive calipers. I certainly wouldn’t do that with my Mitutoyo’s.

-

Someone has a lot of time on their hands. These are all very nice Claude. Thank you for sharing and inspiration.