-

Posts

486 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Rick L

-

Best clear material for large flat windows?

Rick L replied to crowe-t's topic in Tips, Tricks, and Tutorials

You can purchase a .005x24”x24” square sheet of polycarbonate film from McMaster-Carr for under $3.00. -

I helped a friend with his train layout years ago collecting homasote fibers through a jointer. As I recall, he added his plaster material in the same manner.

-

If you’re heat forming, the plastics mentioned will work fine. Avoid polycarbonate films. They’re too tough to work with.

-

You don’t want thin acrylic for flexibility. Too brittle.

-

The thinnest acrylic available is 1/32.

-

To get a flat even half round out of tubing, lay the .08 tube down on a flat surface with double sided tape and sandwich each side with a flat layer of .04 shim stock along the lengths also taped to the flat surface. Sand down the tube length wise with a sanding block until you reach the shim stock.

-

Good question. Unless you have access to a milling machine, I can’t answer that.

-

Another Can Of Testor's Bites The Dust

Rick L replied to oldcarfan's topic in Model Building Questions and Answers

Or if he loves the color that much, he’ll buy one.? -

The old Testors paint was lead based and would cover well. The new version are lead free and don’t cover well without primer. Lacquer will cover better but does not brush on as smoothly as the enamel. The routine process is to wash the parts of mold release agent in warm water with a few drops of Dawn detergent, rinse with clean water, let dry and prime everything before paint.

-

Repairing Paint Chipping - Tamiya Lacquer and 2k clear

Rick L replied to DiscoRover007's topic in Tips, Tricks, and Tutorials

Wow! That chip is huge! I’d sand the whole car down to the bare plastic and start over. ? just kidding. I’m with Pete on this one. I can barely see the chip. A little touch up and no one will notice unless you tell them. -

Unconventional Materials - From the jewelry area

Rick L replied to Jiml0001's topic in Tips, Tricks, and Tutorials

If we all built models the same way, this forum need not exist. -

Loosen the lid on Testors enamel square bottles.

Rick L replied to R. Thorne's topic in Tips, Tricks, and Tutorials

Amazing! 39 replies on how to open a stuck bottle cap.? -

Looking for the "best" '49-'54 Ford Sedan Kit

Rick L replied to Bill Anderson's topic in Model Building Questions and Answers

I think this 49 Ford is a re-pop and I agree with the other posters that this is one fine kit with nice options. It will not disappoint. -

Perfect simplicity.

-

Very clean build. Thanks for sharing.

-

I spent 40 years building mockups, engineering prototypes and mold masters for short run casting. Mostly for the medical diagnostic field. That casting is one of many enclosures we produced for a long time client.

-

Also note that some casting materials, particularly polyurethanes, need to be cast at higher temps in order for their properties to work. Or they become brittle when fully cured. This mold is set in an oven preheated to 150 degrees before injection cast with 2 part urethane mix.

-

Meanwhile, the inventor of that simple little part is laying under a palm tree somewhere, sipping Pina coladas

-

Generally, the longer the pot life the less heat will be produced. If you’re working with small parts with thin walls such as small scale model car parts you shouldn’t have any issues with the castings. The mixing cup on the other hand may be an issue if it’s a fast curing plastic or epoxy such as the reaction Bill experienced. If you’re unsure of the reaction you may get just cast the part and leave the mold and mixing cup outside.

-

Sprayng Molotow chrome; anyone here ever done it?

Rick L replied to Roadrunner's topic in Tips, Tricks, and Tutorials

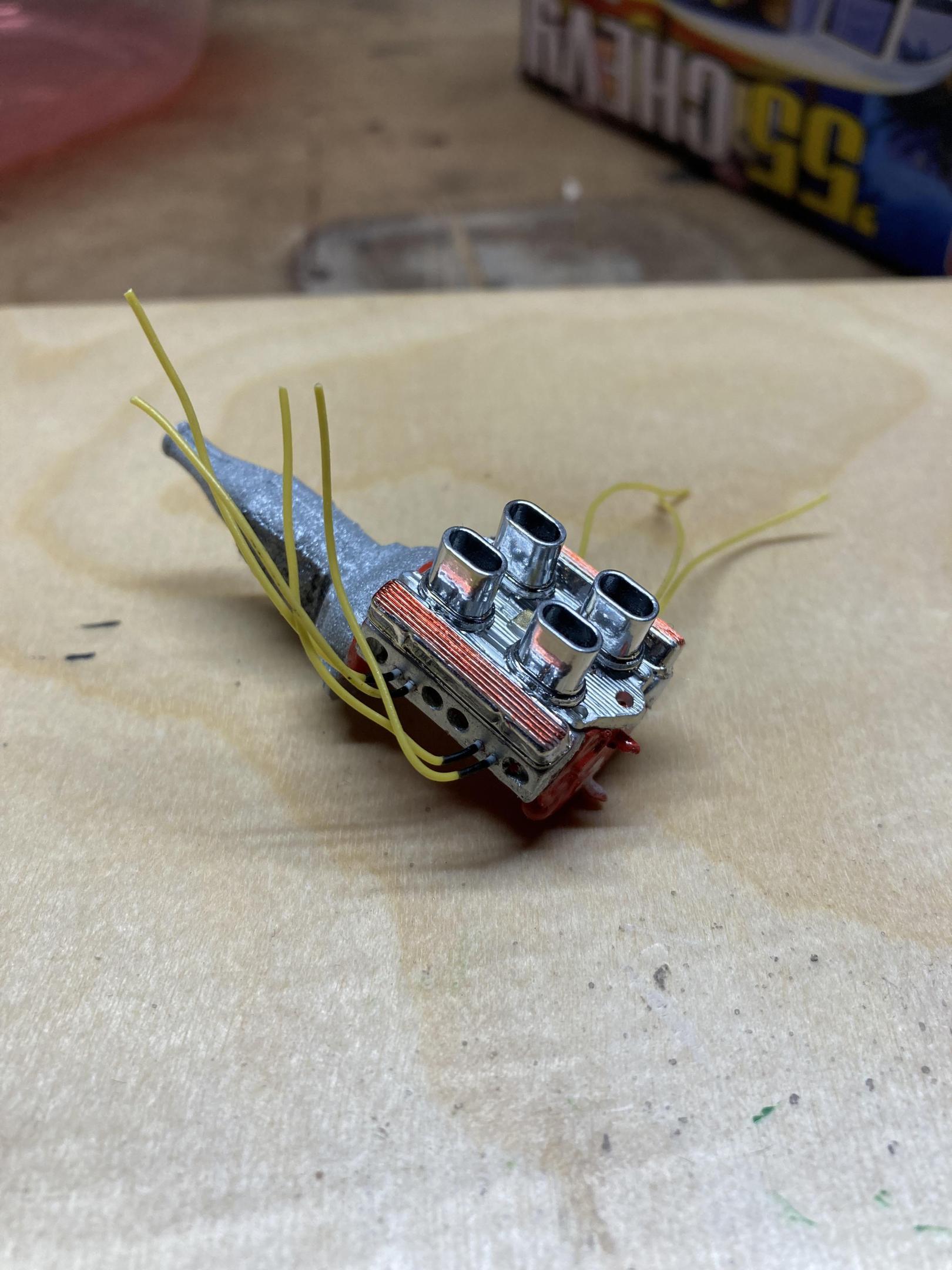

These velocity stacks were made from plexiglass and spray painted directly with Molotow. This was my fist experiment spraying plastic without primer. They’re holding up fine. -

Also works well for mixing bondo or any other polyester resin.

-

How Stable Is The Plastic Used In 3D Printing?

Rick L replied to oldcarfan's topic in Model Building Questions and Answers

3D models are printed by FDM (fused deposition modeling) or SLA (stereo lithography). Most FDM parts are printed with styrene and are fairly stable. All SLA parts are formed by a UV sensitive resin, are hygroscopic and expand over time. Don’t confuse the SLA resin parts with your cast resin body parts that are molded with a two part polymer. These are also fairly stable but can warp if not properly stored over time. Like sitting in a box jammed with other parts.