-

Posts

1,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by BK9300

-

FDNY Wrecker

BK9300 replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

It always amazes me how much, even at the early stage of a build, a coat of primer brings the work to ‘life’. Good start on the rad and looking forward to seeing how you do your under lift. Great looking engine in the foreground, too! -

Cyber punk ‘88 Dodge Daytona/Mercedes C9 kit bash

BK9300 replied to Steve H's topic in WIP: Model Cars

I agree with Greg - the interior is marvellous and the detail painting on your rear suspension really highlights the individual parts - very clean work! -

Looks awesome, Jeff! Am I seeing scratch built washers, as well?!

-

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

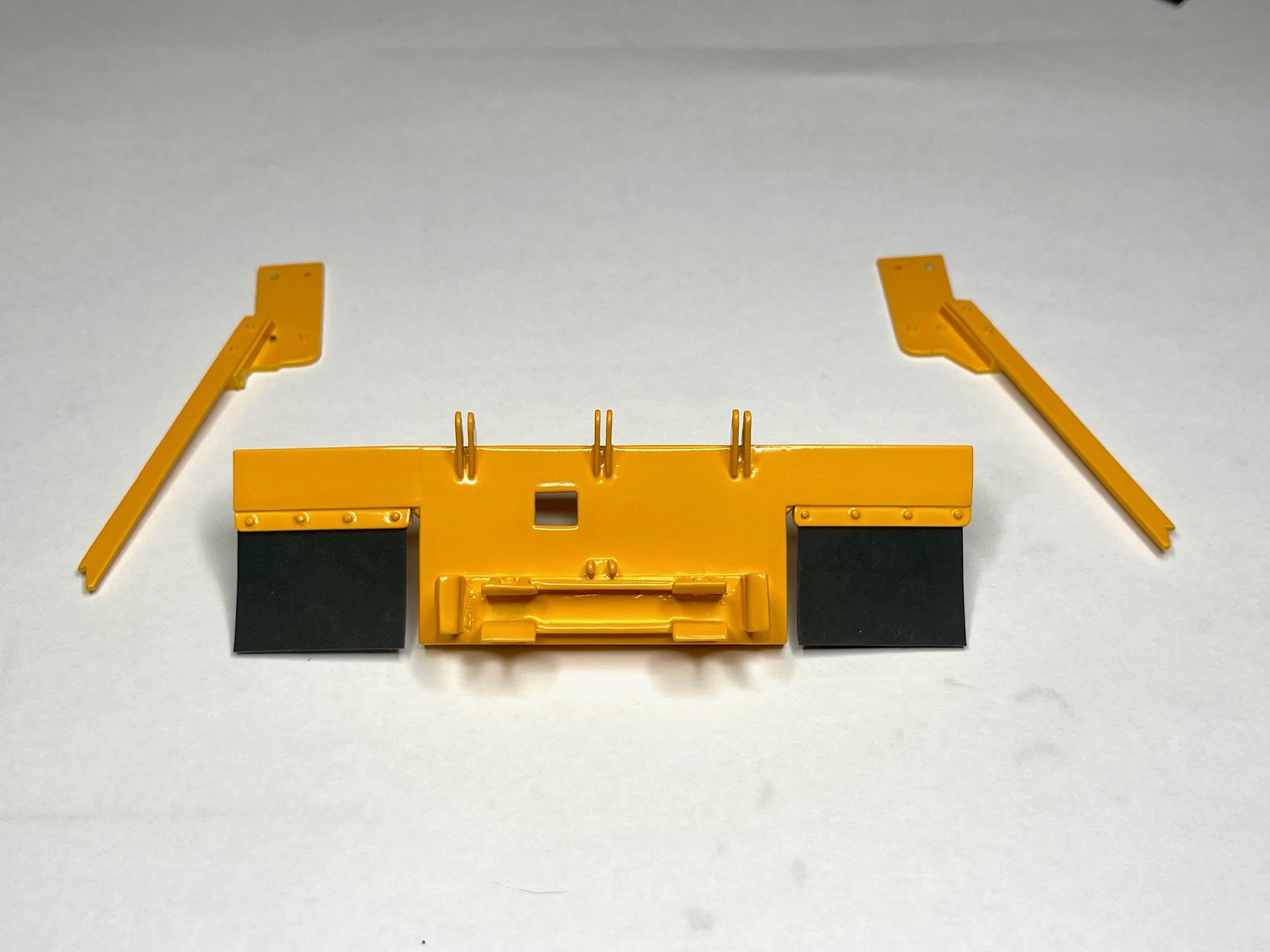

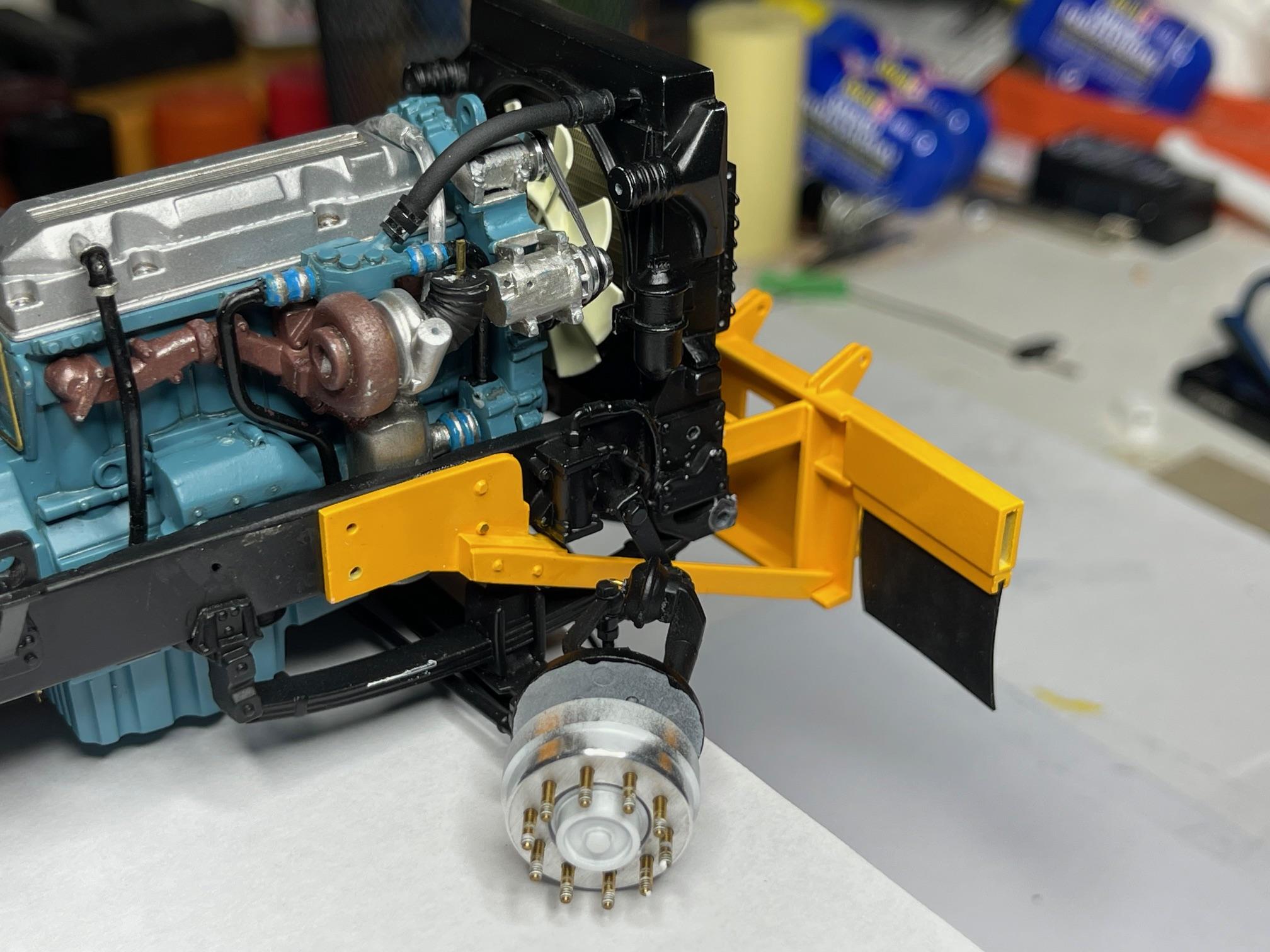

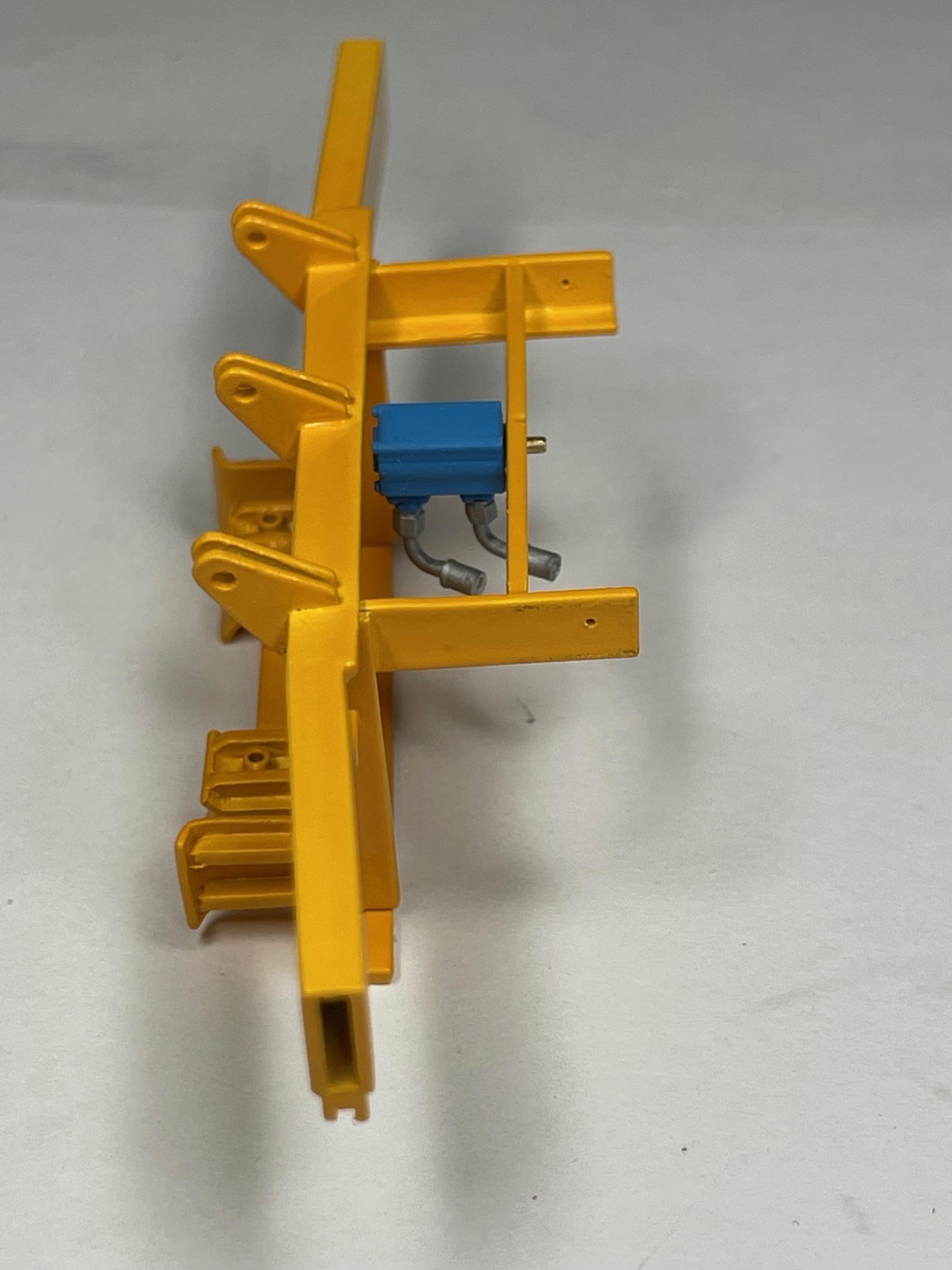

Another good step taken today - got the front plow lift group attached to the frame, along with the two support braces that bolt to the frame. End result looks good, but created a bit of a mess that needs to be addressed. That will have to wait till tomorrow now, while everything sets up. Hopefully, tomorrow sees all but two of the loose hydraulic hose ends attached to their fittings! Front mud flaps attached - wouldn't have been able to do this as easily if I had waited until lift group attached to frame; two frame braces ready to be installed as well So, this was a bit of back and forth - had to scrape some paint away from the part of the lift group that slides into frame, but over did it and now some touch up painting needed. I prefer styrene glue instead of CA glue when attaching styrene to styrene and just over cooked the paint scraping. Same thing when locating the frame braces for the lift group - while scraping away paint from the frame, managed to damage the paint on the springs (both sides!), so more touch ups needed. Still, very happy to have these pieces set in place! Better shot of excessive paint scraping damage; two bigger bolt heads need to be added to each frame brace Can see where frame brace attaches to bottom of lift group (and paint damage to the front spring - more touch ups!) One of the reference pics I used in the fabrication of these pieces Remaining work for frame braces, apart from bolt heads, involves making top and bottom shock mounts, making shocks, re-drilling frame brace plates for pass through air lines to front brake pots and re-doing the air lines. Apart from finishing the hydraulic line connections, I can now also carry on with finalizing the plumbing for the air conditioning condenser to the receiver/dryer mounted on side of rad. And maybe, might be able to get this truck up on its wheels and tires this week - that would be a milestone, for sure! -

I think any improvement of a piece beyond how it came off the sprue adds to the build's character, so, I agree with Ron and sure wouldn't call that kind of effort a waste of time.

-

Pete 359 tanker with trailer

BK9300 replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That’s a sweet looking trailer, Jürgen - you’re going to need your new display case sooner than you thought! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks for the kind words, Steve! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I appreciate the comments, Jeff and I heard a few stories other way around, about some mailboxes taking a beating from our plows, mostly in rural areas, and the angry calls to let us know about it! All our trucks had some version of warning/flashing lights on the wing plows - this is a pic of the real truck I’m modeling -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks, Scott! Am very pleased with the parts that Bren printed and the pump looks its part there on the lift group. Jeff made a good point about the hoses for the front lift needing some wear protection, which I will do, so also needed to go back and finish that for the fuel lines! -

Another terrific build, Donald! Really like the wheel lugs detailing and all the work under the car as well. Even if no one knows about it, you do. Looks great!

-

Pete 359 tanker with trailer

BK9300 replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That's a great idea to cover up the screw heads! Works perfectly -

A beautiful, beautiful build - well done, Steve!

- 40 replies

-

Resto Rod Autocar

BK9300 replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That’s a lot of work accomplished in all those small details! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks again, Lee - a bit slow going this month. Hard to get more than a couple hours in a row at the bench, but still carrying on! -

Pony Express 70s BB/FC ex M/T Pinto

BK9300 replied to Ian McLaren's topic in WIP: Drag Racing Models

It’s a pleasure to watch these builds start, simply, and come together with all their characteristic complexity - the brass work always fascinates me!- 63 replies

-

- brass chassis

- not a kit

-

(and 2 more)

Tagged with:

-

1941 Autocar U-80-T tractor

BK9300 replied to RoninUtah's topic in Model Trucks: Big Rigs and Heavy Equipment

Colourful build, Lee, and an interesting introduction of this hard working truck! -

Ditto - Best of luck! Maybe post a pic of your Falcon at the contest?

-

Often said - you do a tremendous amount of enhancements during your work on your builds. Always turns out great!

-

Pete 359 tanker with trailer

BK9300 replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Going to be a terrific truck and trailer combo, Jürgen - fun following your progress! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

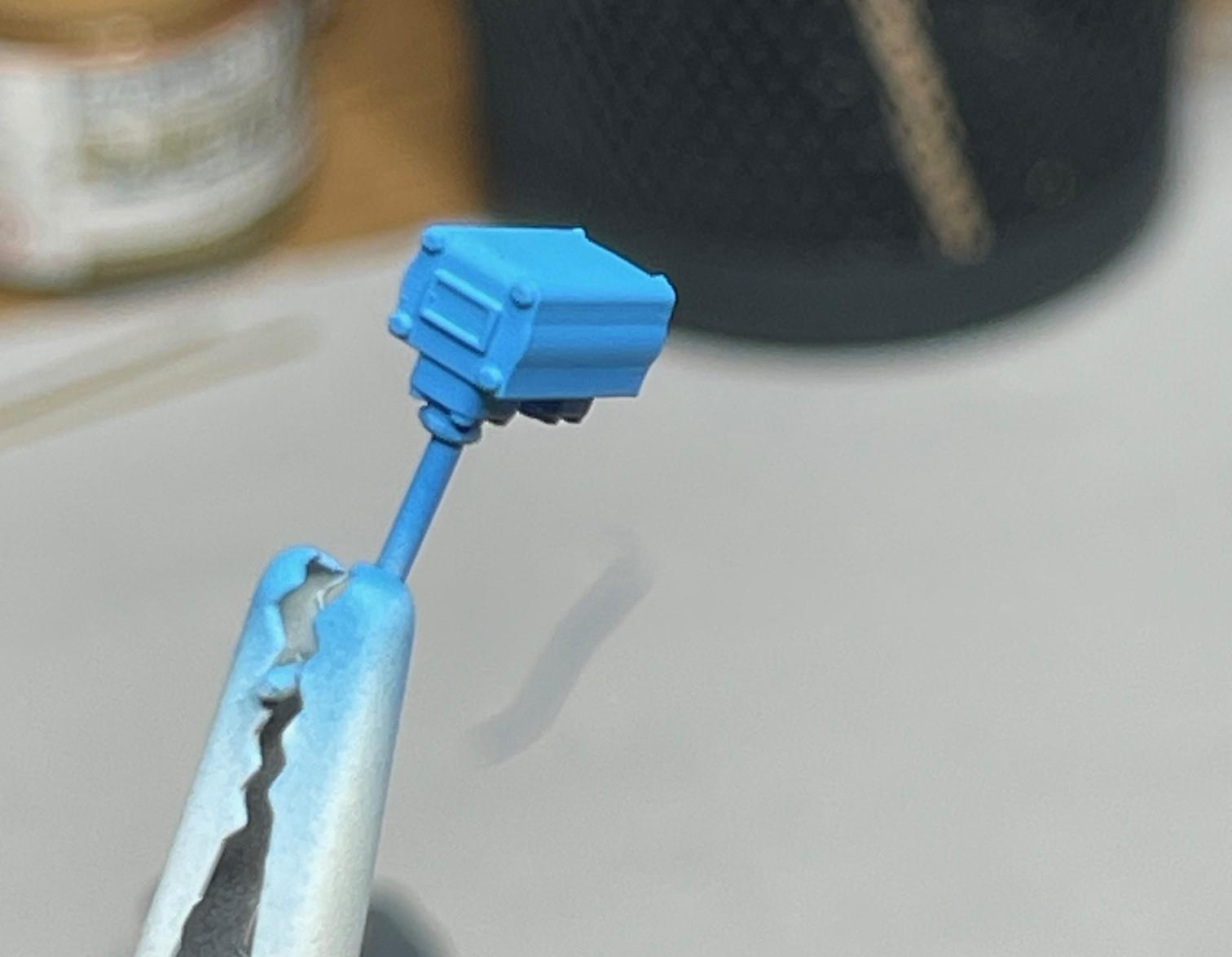

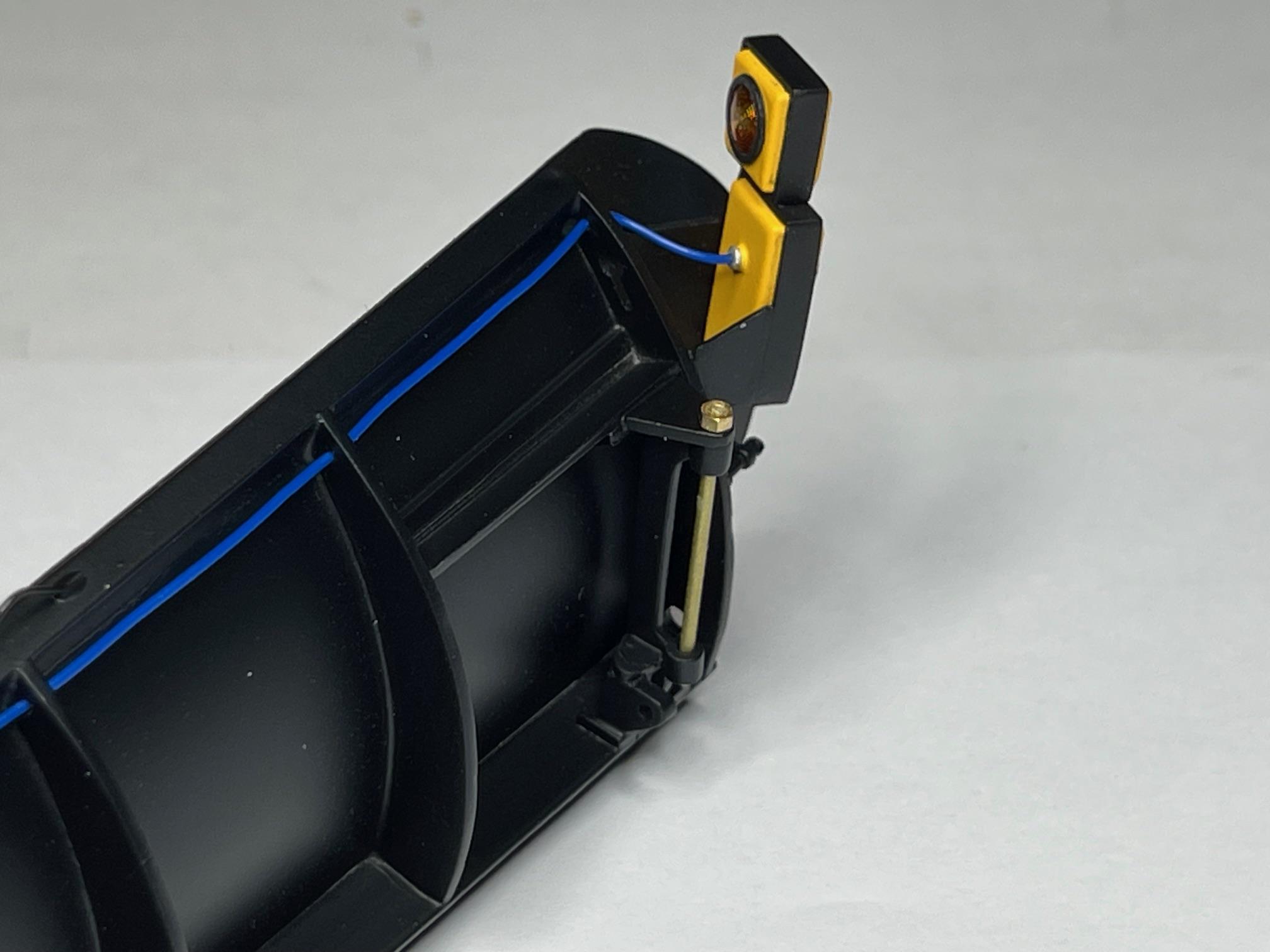

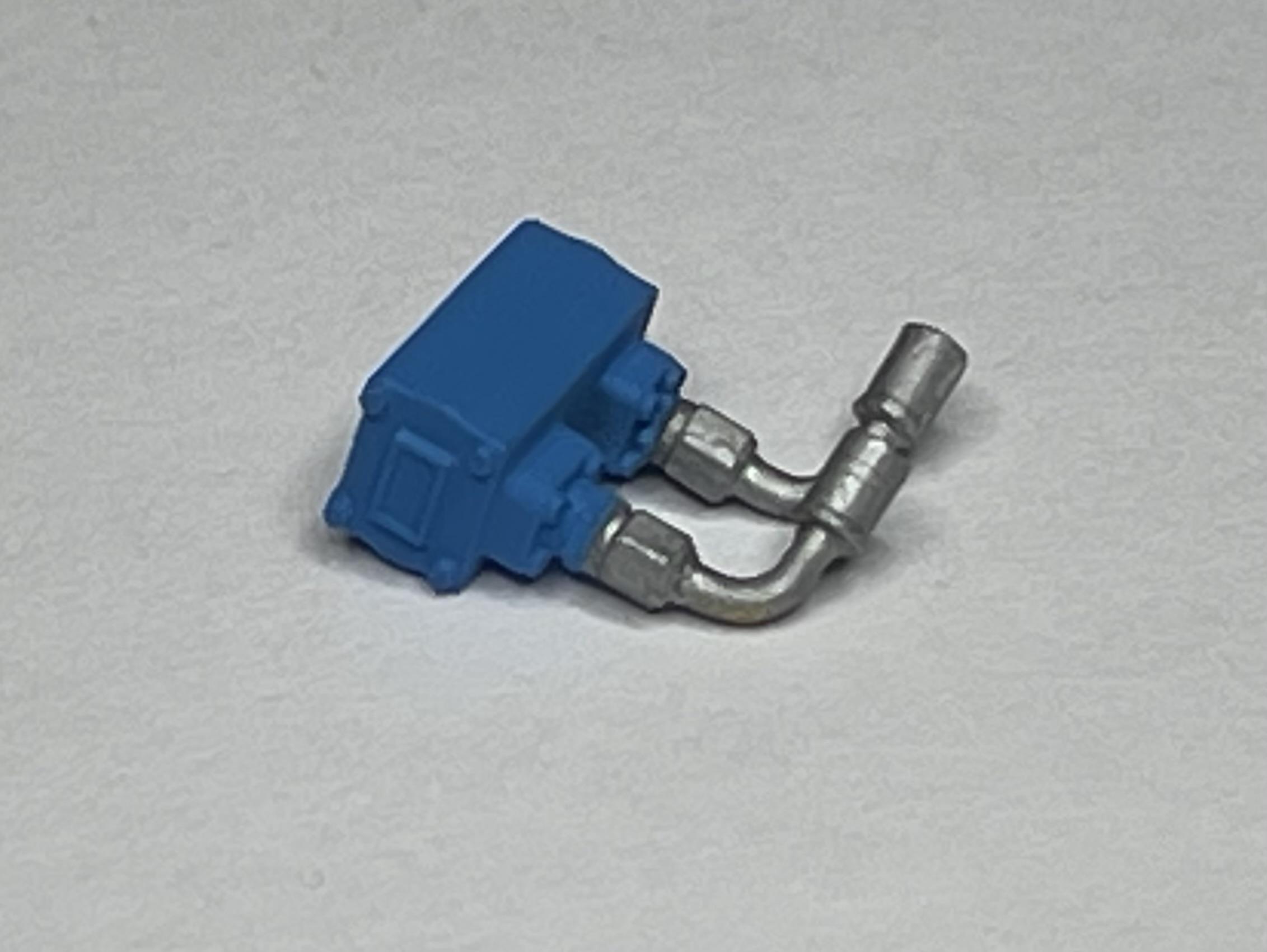

Managed to work on a couple different areas of the truck today, catching up on some loose ends and continuing on with a bit of new stuff. Finally got the warning lights fitted into the wing plow and ran the wiring to it. Finished painting the hydraulic pump and its fittings yesterday and got them put together today. Also managed to attach the pump in place on the plow lift group crossbar - good day today! Mock up of the wing plow, and its hinge attachment, with the 'plastic' light housings in place (and the added lifting hook!) Wiring run to light housing - brass pin needs to be painted yet - the hydraulic lift arm attaches to this pin Pic of the rear flashers This is a pic of a real truck's 'Vickers' vane pump (not the truck I ended up modelling) and part of the lift group Replica I made in Sketchup and printed by Bren Fittings in place (weird how the light changes from one pic to next - didn't think I did anything different!) Pump mounted in place on the plow lift group Hope everyone has a good rest of the weekend! -

1941 Autocar U60

BK9300 replied to RoninUtah's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That's a very sharp colour combination, Ron and the truck looks great with the vintage trailer. I see there's a dusting of snow in the background - must have been chilly taking the pics!