-

Posts

4,779 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

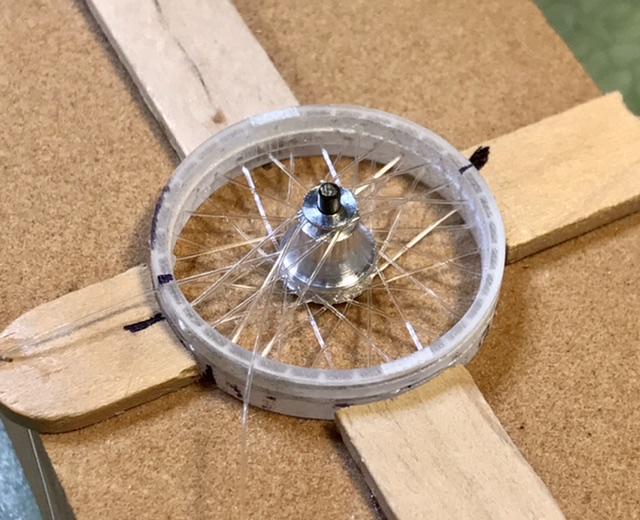

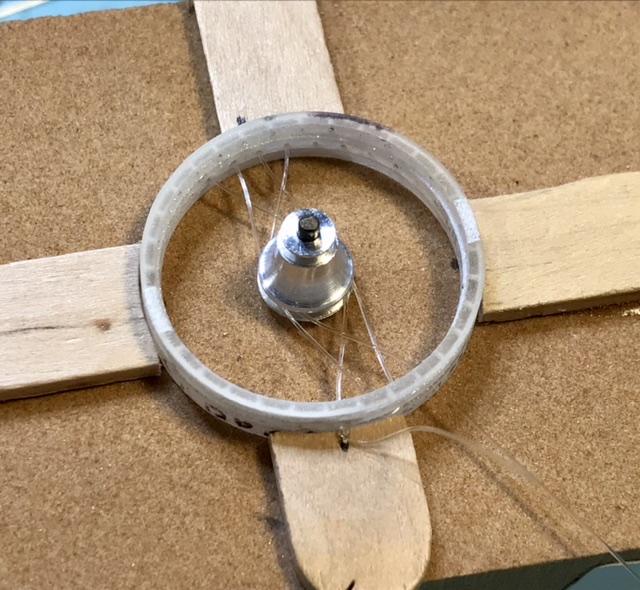

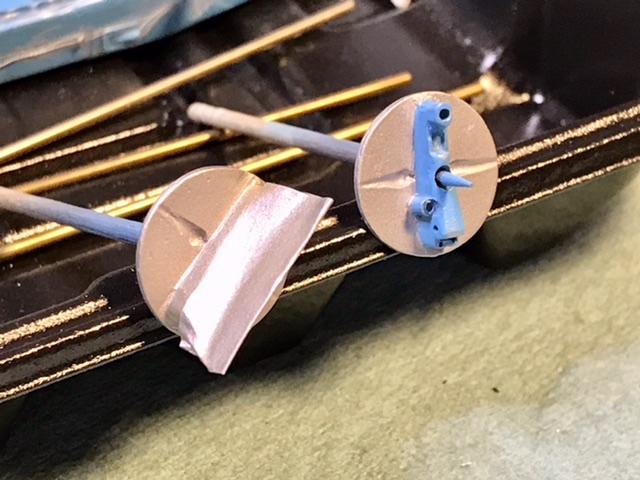

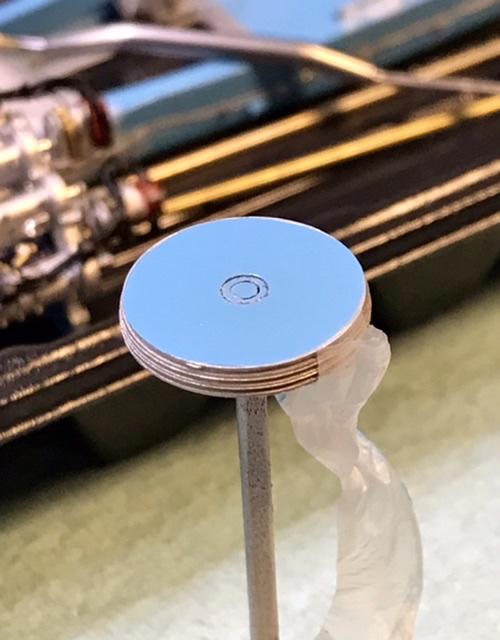

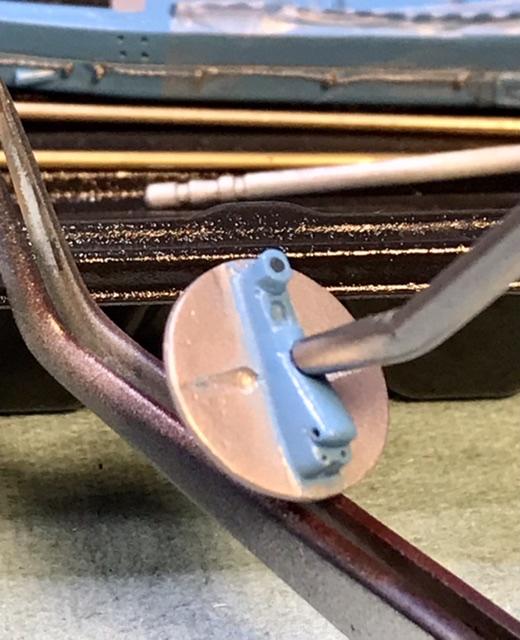

Hard to tell - but the rims have shoulders - the castings need a softer “shape” or profile …. The wheel to the right has these changes …

-

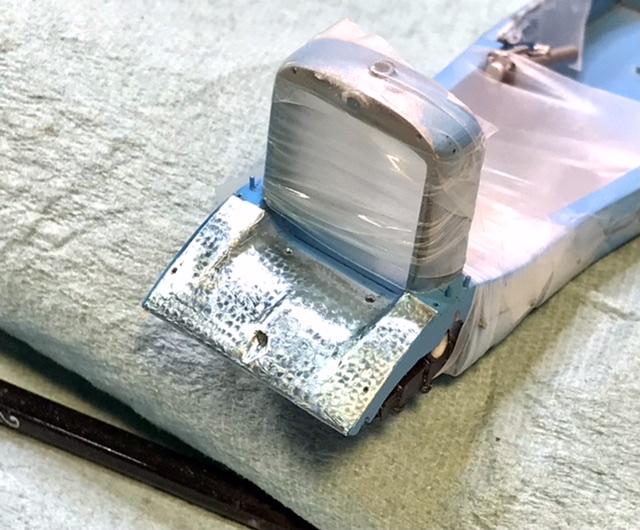

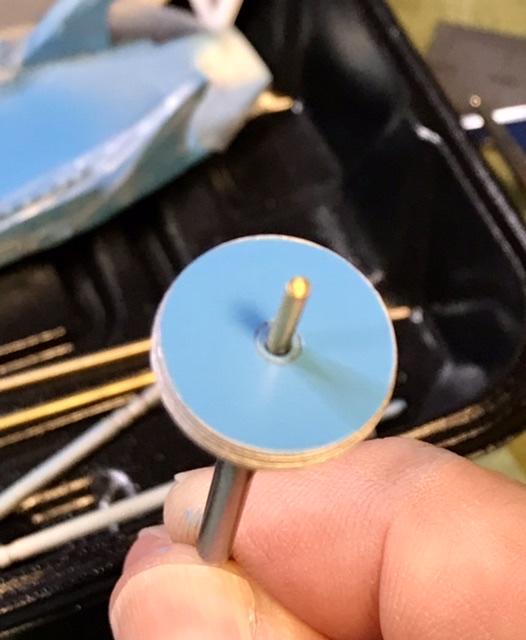

Coat of tamiya primer - rattle can - all good - but the paint reveals some more work … made it past page 13 w out a disaster - huge relief …

-

Ball game … for the record - hurricanes 8 - Hokies 5 right now Bugatti fan is thinking : what the devil is a Hokie ?

-

-

-

-

-

The wiring pattern was posted by Pico on an earlier page - wired while i had a college baseball game on the radio … 1st inning …

-

Dept of Corrections …. The first wire wheel that i laced used steel wire rather than fishing line - not so good - ive clipped apart the offending wires - no damage to the rim - its now ready for a new set of fishing line wires ….

-

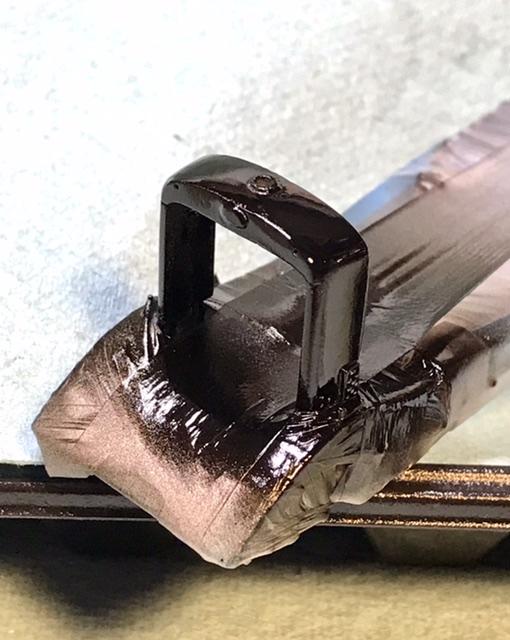

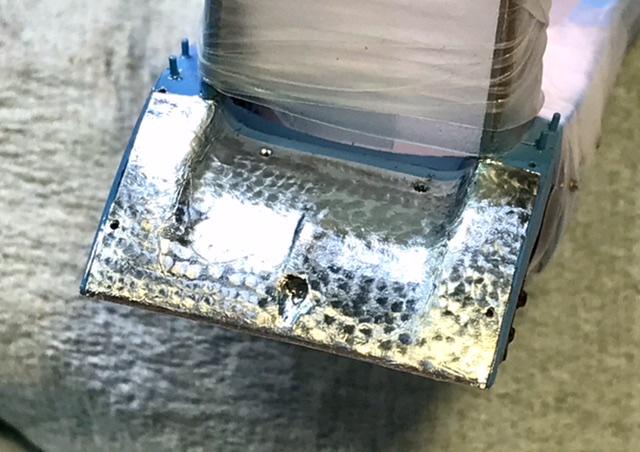

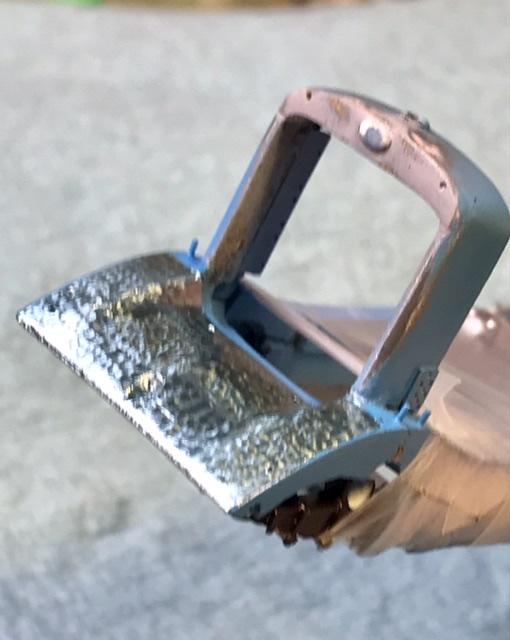

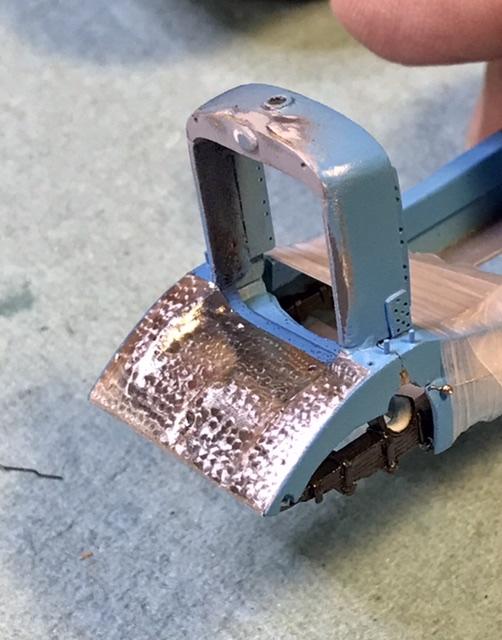

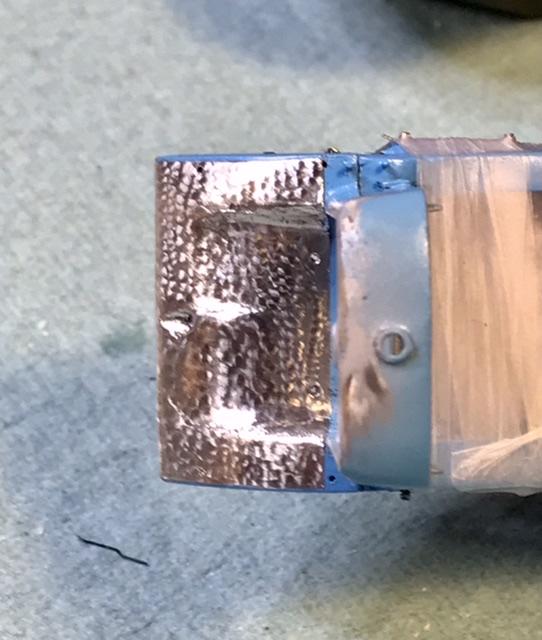

Back in Black … prepping the radiator shell for the shiny stuff - using Alclad Black - frame is covered in para-film …

-

Your method - or Colmer’s - are great for a flat surface peice of aluminum that you then place onto the model - when i apply this finish to the metal body work i can’t use a fixed tool attached to a mill or a work station - but ill use a hand peice and some sort of guide taped to the surface of the body- meantime - ive air brushed a mix of clear and transparent blue to this front panel - not sure how well it shows on a photo - all of this car’s bodywork had this unique blue varnished finish -

-

Eagle Gurmey Weslake 1/12 MFH

absmiami replied to primabaleron's topic in Other Racing: Road Racing, Salt Flat Racers

Correction best looking grand prix car … of ANY era … -

Ive got the Otaki 16th scale Bertone Jaguar Pirana - parts trees look like the Mustang - tjere is one for sale on ebay right now - do not - i repeat - do not - spend what the seller is asking for This kit - unless you must have a large scale model of everything Jaguar …

-

This time w Tamiya masking tape strips- got sharper lines silver/blue on the uprights - problem fixed …

-

Front suspension - hubs, carriers, uprights - painted w Tamiya silver and Ukraine Air Force blue …. Masked with Parafilm - some bleed-over on the uprights - to be corrected

-

I’ve applied some engine turned patterns with a rubber “bur” chucked into my Foredom … worked sort of - without the abilty to tape a “guide” to the surface of this panel - the swirl pattern wanders around - it should appear as nice neat rows - like a field of crops viewed from the air - didnt get this look - but I’ll seal it and apply a clear blue finish … onward …

-

Well. They tried you’ve got something to start with - and this is bound to be the only large scale ‘71 Mustang you’ll find ..