-

Posts

9,567 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

I'm having trouble with hobby cement.

NOBLNG replied to Plumcrazy Preston's topic in Model Building Questions and Answers

Thin super glue (CA) will work on close fitting parts, but you will need an applicator like “glue looper” or a home made one in order to apply very tiny amounts. I prefer medium CA as it is easier to apply tiny amounts and doesn’t set instantly like the thin stuff. Either will bond to paint, but the joint will only be as strong as the paint-to-plastic bond is. The best thing to do is get some .020” brass rod (or any tiny wire) and make pins to join all the finicky little parts before paint. Then you are not relying on the glue for the strength and it saves a world of grief during final assembly! ? -

I think I used .010”x.030” flat strip for the seams on the roof, and .030” half round for the chrome trim. You can sand the half round slightly to make a half oval shape? I cut the first piece I installed just a hair long and glued it in place. Then made the second piece overlap it. Then with a very sharp (new) blade, I trimmed both strips with one cut.

-

Can you right click on the pictures on Fotki and save them to your computer? Then upload directly to your post by clicking “choose files”?

-

Why do people dig up these old threads???

NOBLNG replied to Force's topic in General Automotive Talk (Trucks and Cars)

I agree! I always search the site first if I am looking for tips or techniques, or examples of models I intend to build. I would rather read a dozen 1 page threads than one that is 12 pages long.? -

The Ukrainian 6447 5247H Titan

NOBLNG replied to tiking's topic in Model Trucks: Big Rigs and Heavy Equipment

Wow, nice work on that rig! And the forklift too!? -

Very nice. Good job on the woodgrain!

-

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

On a related note, I just tried another test with 1/16” round. The Tamiya QS cement made the bend snap. The Plastruct did not. I got the Plastruct on my last trip to the hobby shop cause it was on sale. I can see why because it sure doesn’t weld styrene together the way the Tamiya does!? -

Yes, thanks Guys! Things seem to be OK now.?

-

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

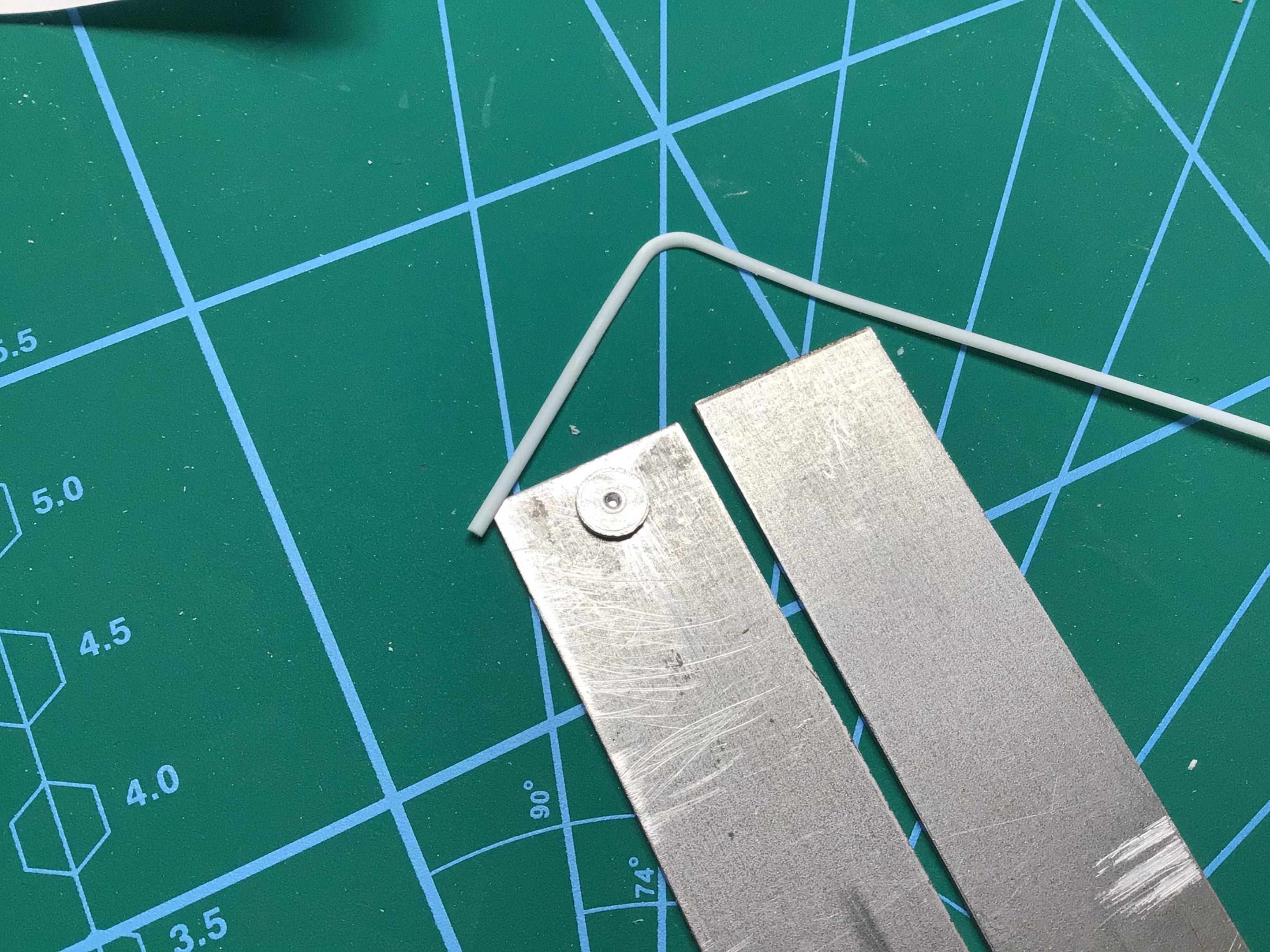

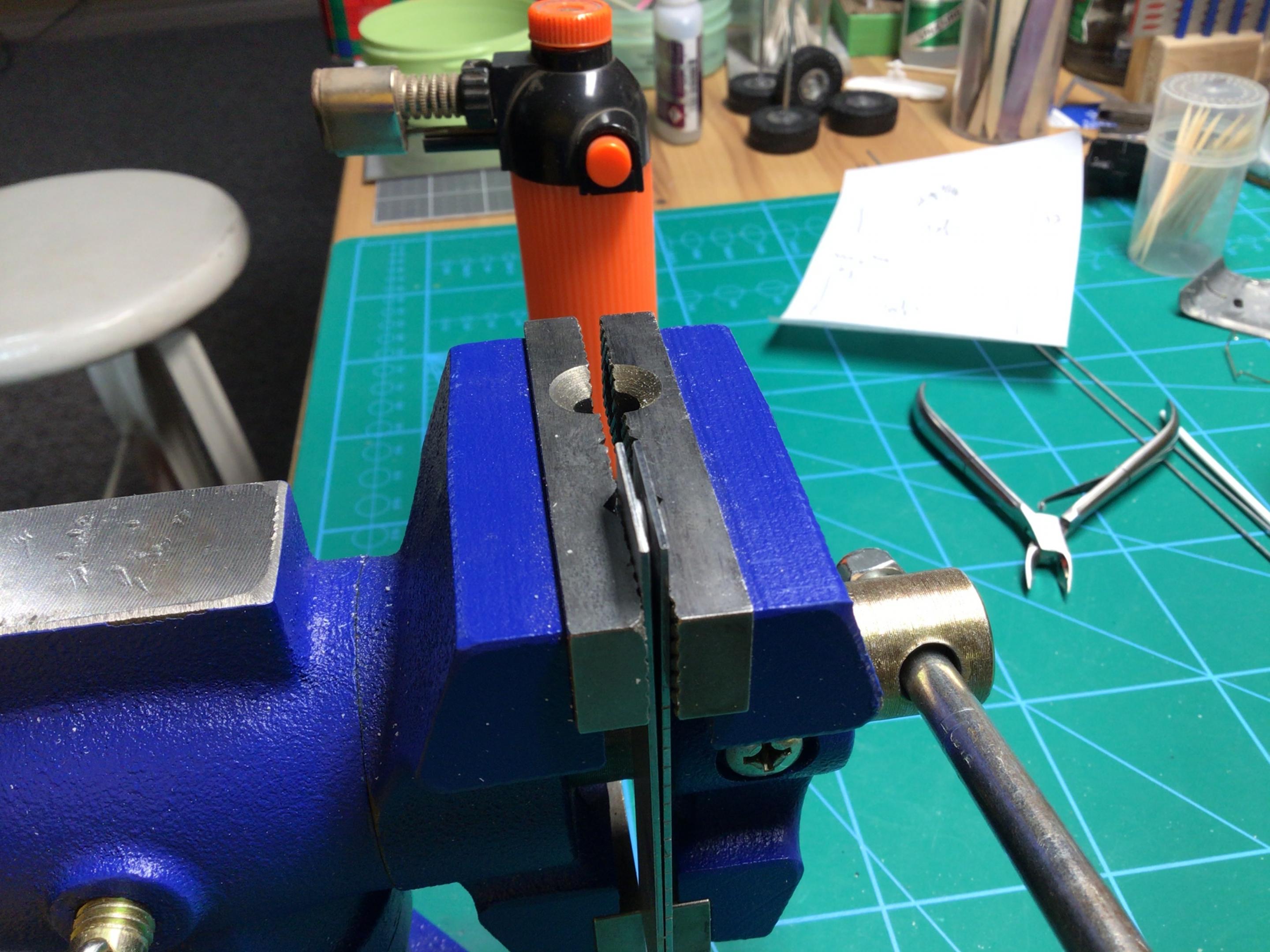

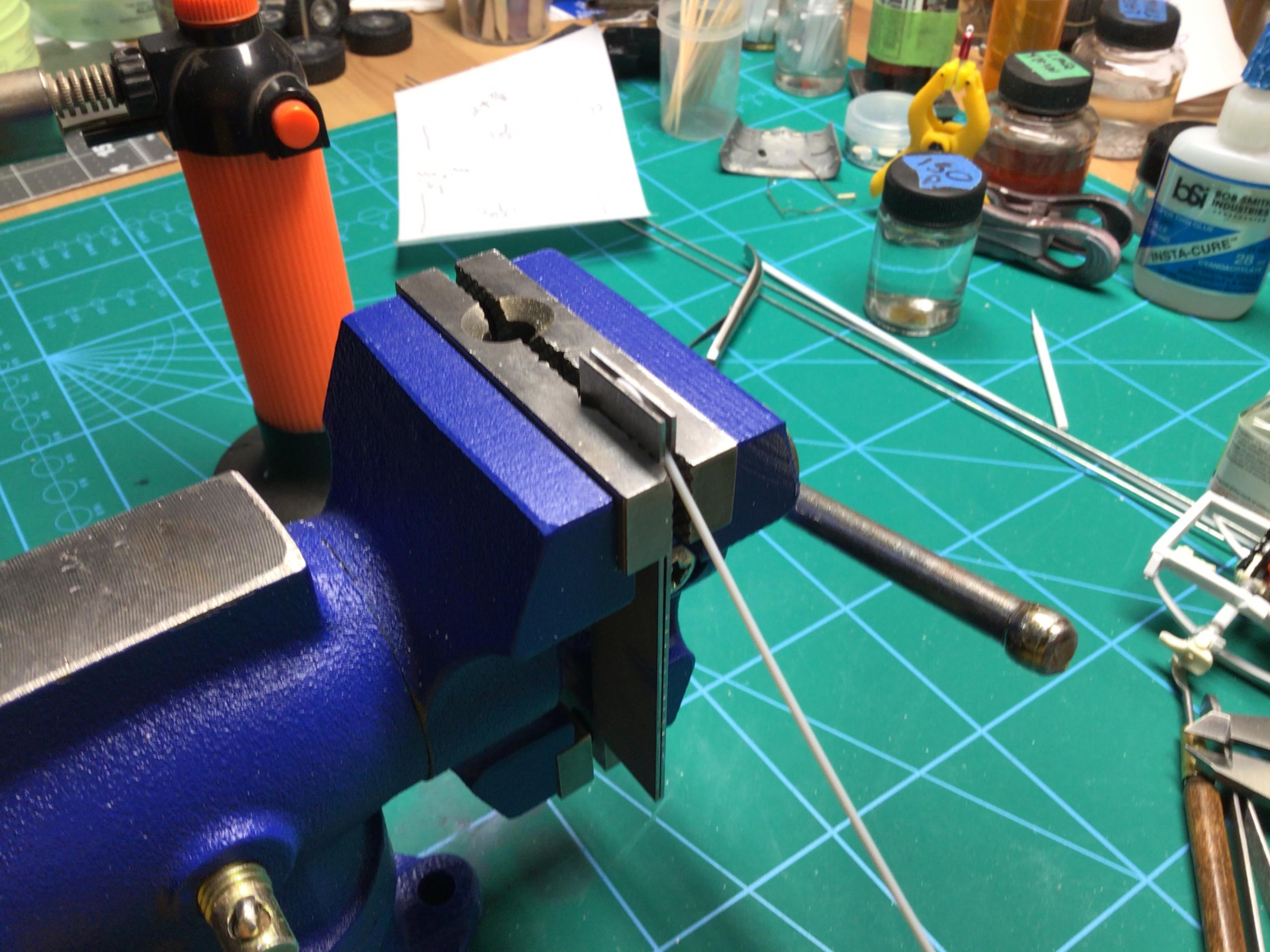

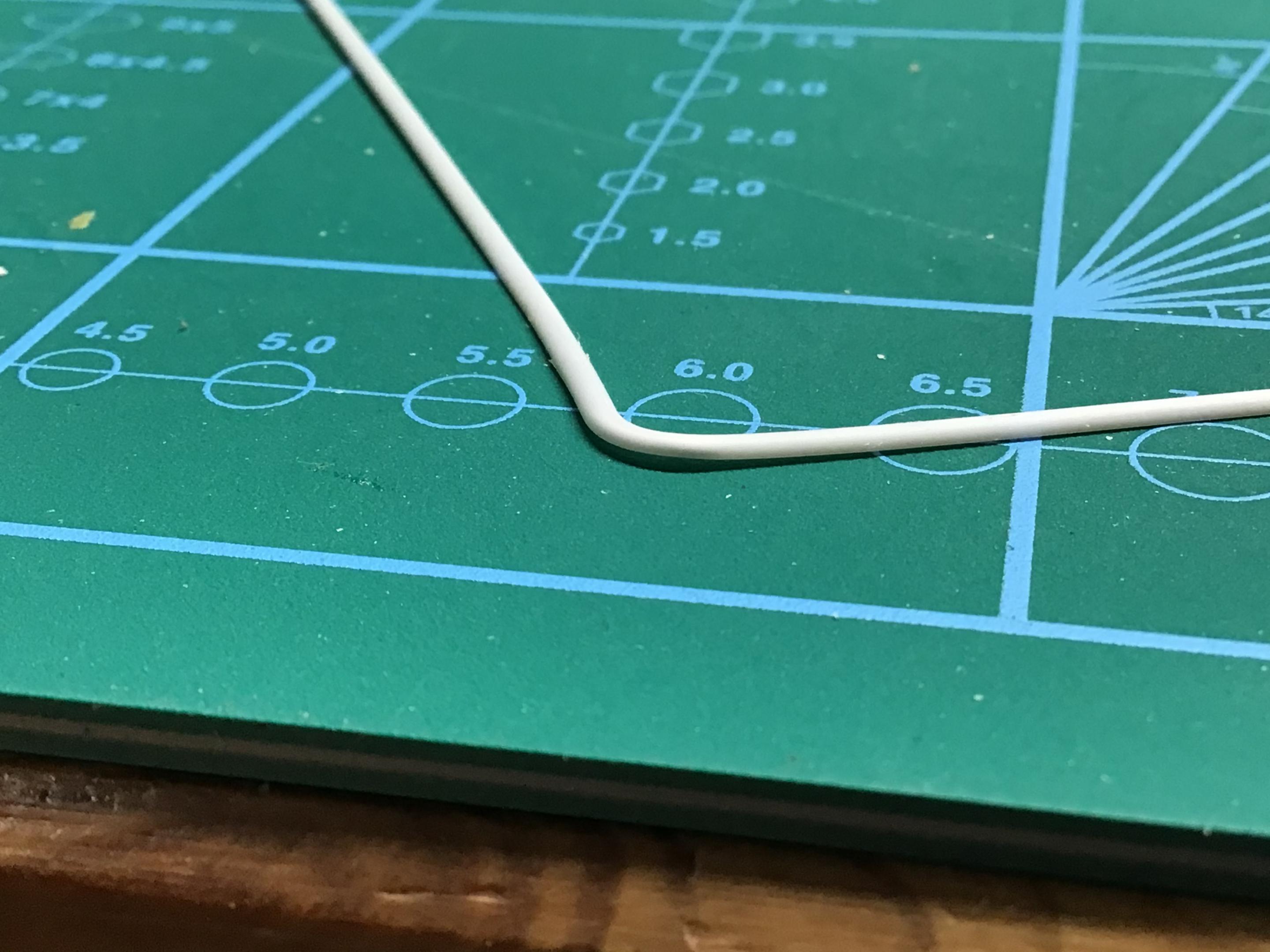

I just tried an experiment. I heated the two plates clamped in the vise slightly. Then put the .060” half round in and bent it around the .030” spacer. It stayed very nearly flat. -

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

That is when it usually snaps for me. What size half round and what radius are you using? Any pics of what you are trying to do? -

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

The OP could possibly bend round stock of the same diameter, sand the bottom half off and use the curved section? Not ideal as it makes for joints in the trim, but a possibility? -

I see it in this thread now. When I first posted in this thread on Wednesday, it was full screen. None of the threads in “under glass” display it and only some threads in other sections??? Edit: Steven’s ‘65 Plymouth thread does it in the under glass section.

-

Tribute T Closed cab Pickup

NOBLNG replied to bill-e-boy's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Very cool project! I like!? -

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

I have also heard that coating the strip with solvent and letting it “soak” for a while to soften the styrene before bending may work. I still think it may snap, but you could try a test? -

I agree, the roof change looks great on this car.?

-

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

Solvent glues will only work for styrene to styrene joints I believe. To glue anything to resin you would need CA or epoxy. I’ve never tried a PVA (white glue) or canopy cement, so I don’t know about those? Best to shape the strips to the contour needed beforehand so the glue is not tasked with holding the shape, especially if it’s a sharp curve. -

What New (Modeling) Technique Did You Try Today?

NOBLNG replied to Snake45's topic in Tips, Tricks, and Tutorials

Where’s the orange peel when you want it eh? -

How often do you guys do models

NOBLNG replied to youpey's topic in Model Building Questions and Answers

I am retired also, so I work on them everyday unless the wife comes up with a plan for the day. I usually have 2 or 3 going so I am not tempted to rush the paint and glue drying...but this scratch building is obsessive. -

Bending plastic for trim curves

NOBLNG replied to Len Woodruff's topic in Model Building Questions and Answers

I have had curved styrene strips break the instant that I applied a solvent cement to them. I wouldn’t think CA would do that If the strip is already preformed to the finished shape. I have also used 5 minute epoxy which allows you time to play with the positioning, but it does squish out a bit and requires cleanup. -

‘54 Willys P/U

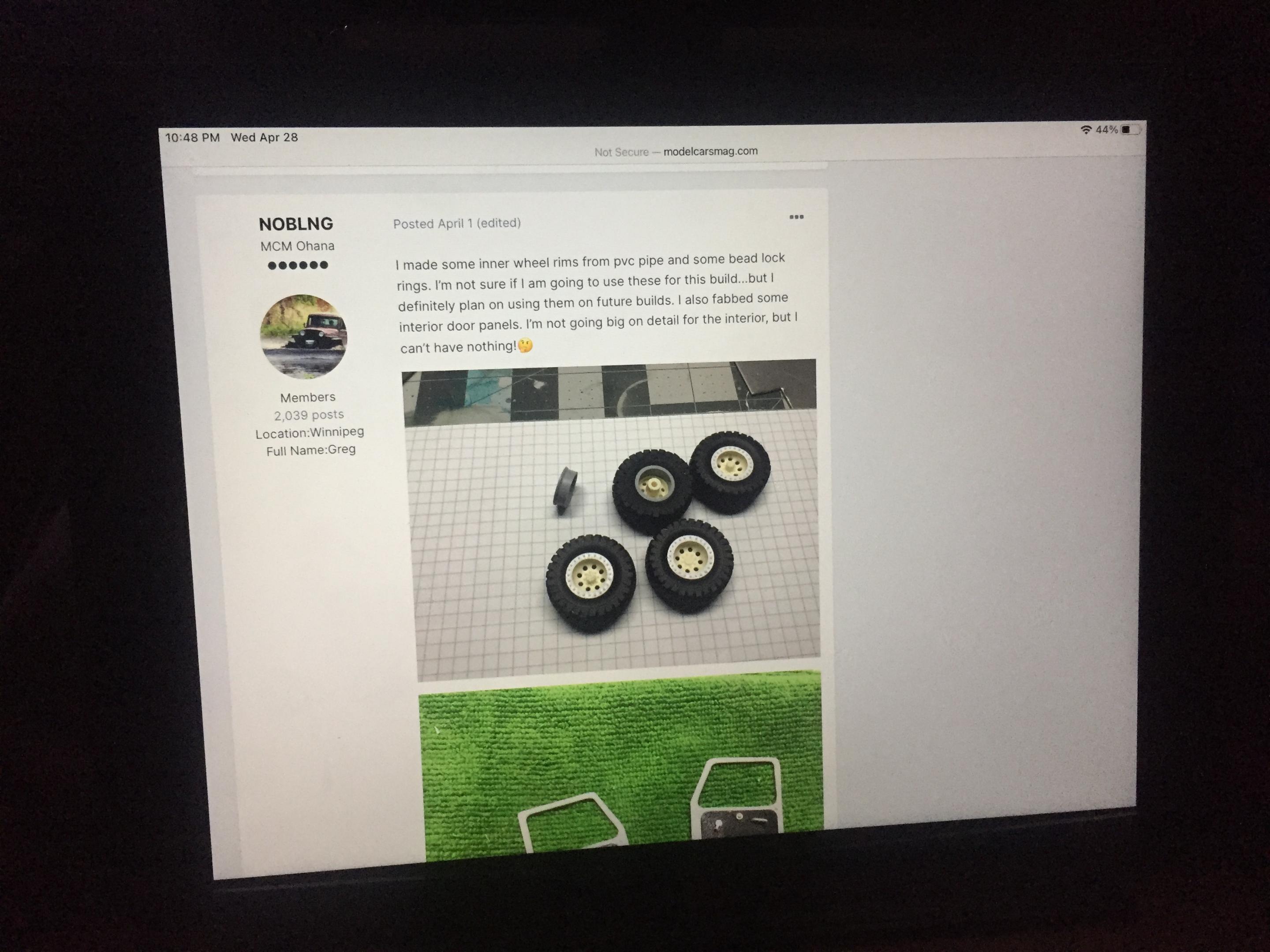

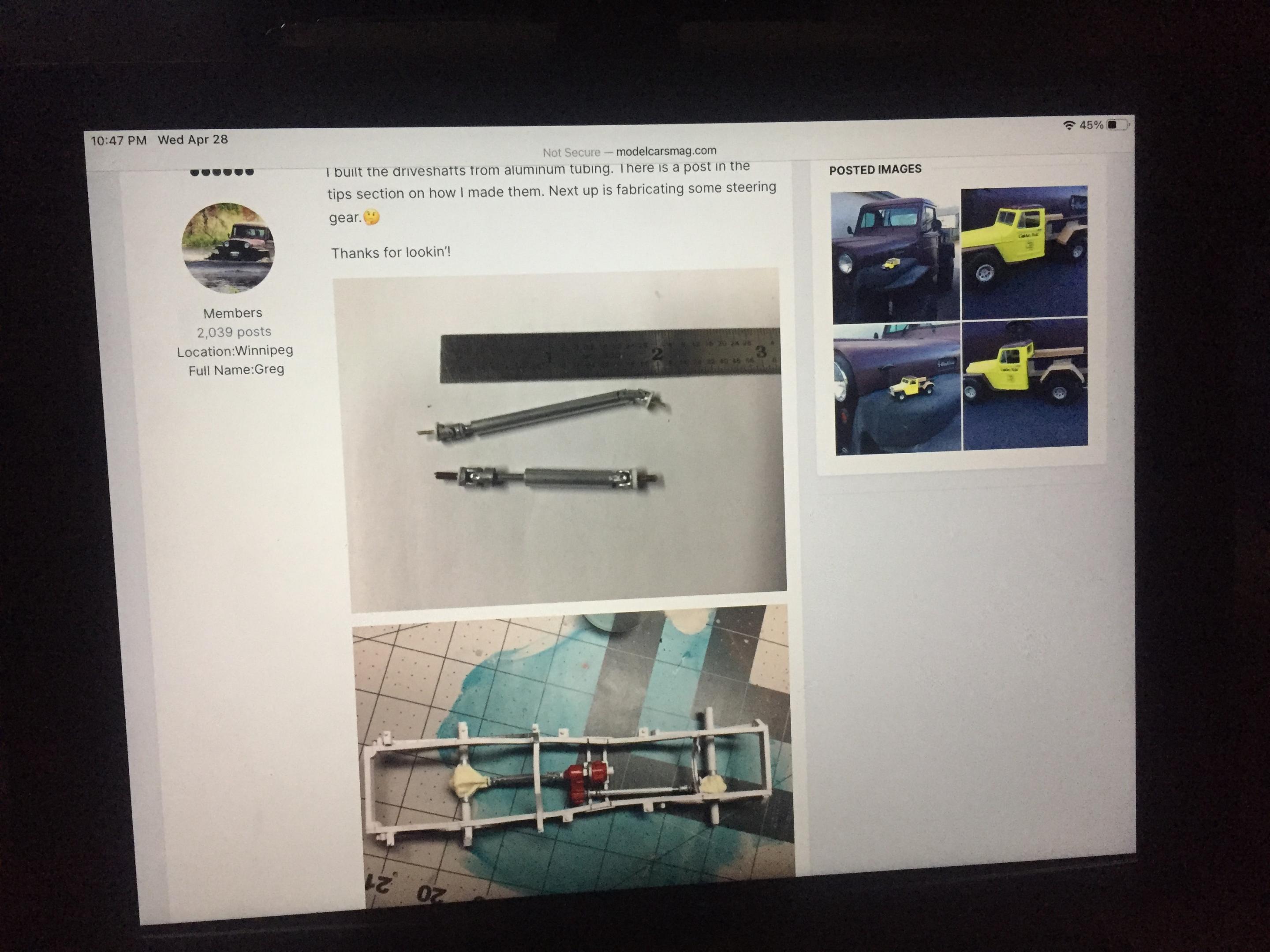

NOBLNG replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

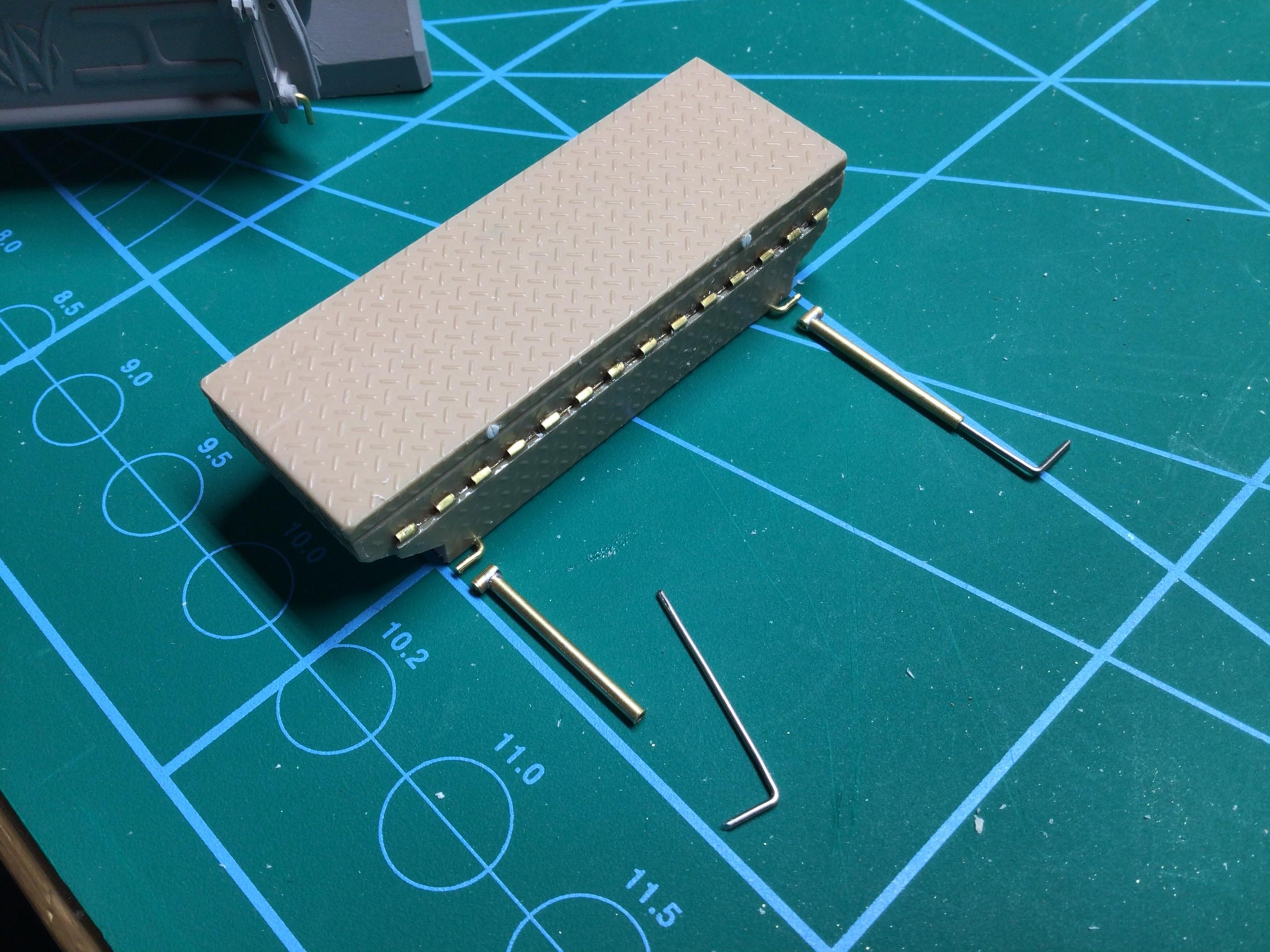

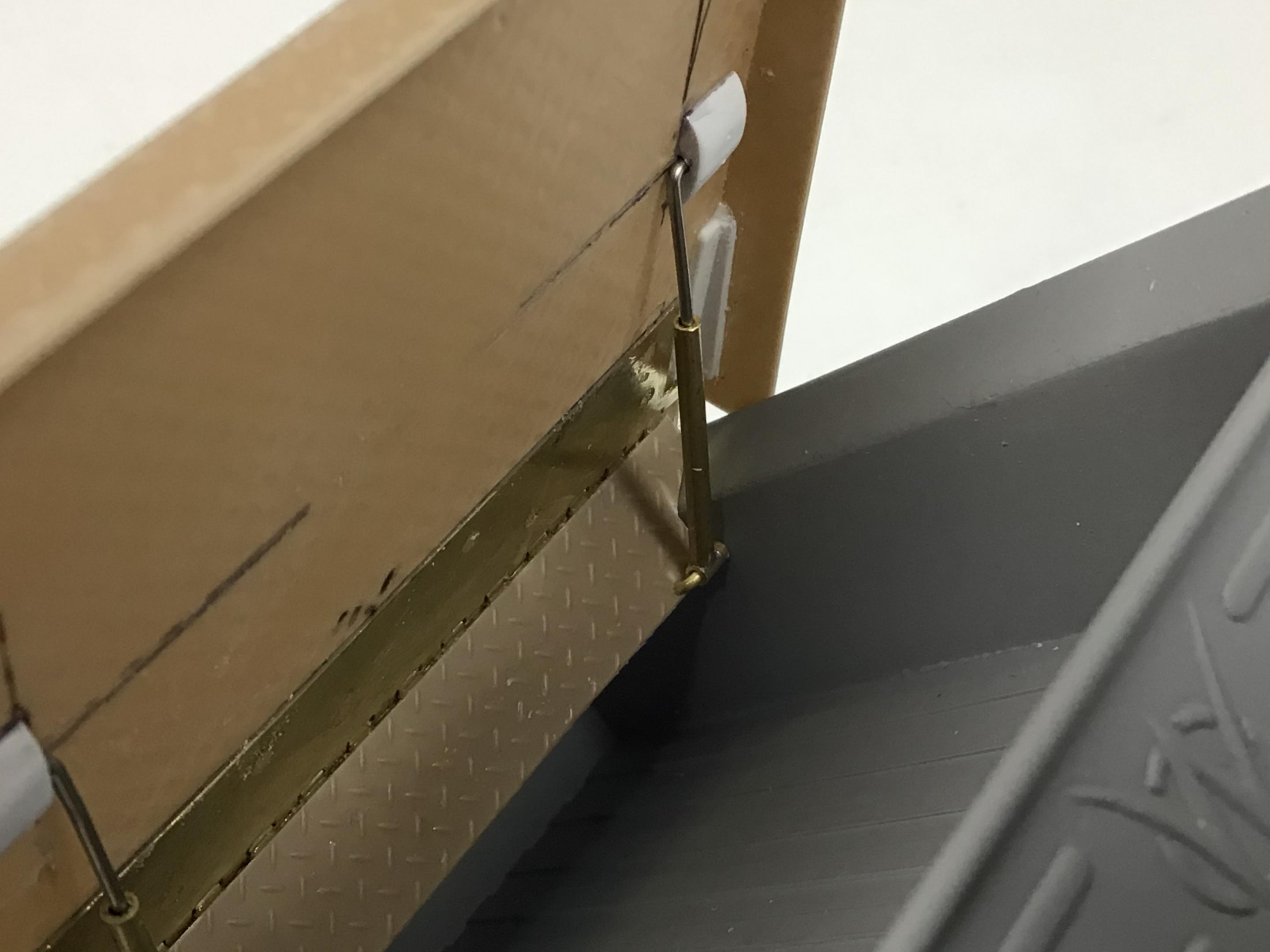

Thanks Steve, Anton, Tom! ? I didn’t like the styrene plank and screws holding the hinge onto the toolbox, so I got rid of them. I epoxied the hinge on and camouflaged the holes. The next items I have to fab are some bumpers and an exhaust system. -

I don’t see any arrow pointing right. There is an ad at the top of the page. When I close it, an arrow appears on the left that brings the ad back when clicked.

-

Since the update, some threads have 1/3 of the screen on the right taken up by “thread statistics” and the actual post section is only 2/3 of the screen on my i-pad. This particular thread is full screen.? Has anyone else’s display gotten smaller and is there any way to get back to a full screen?

-

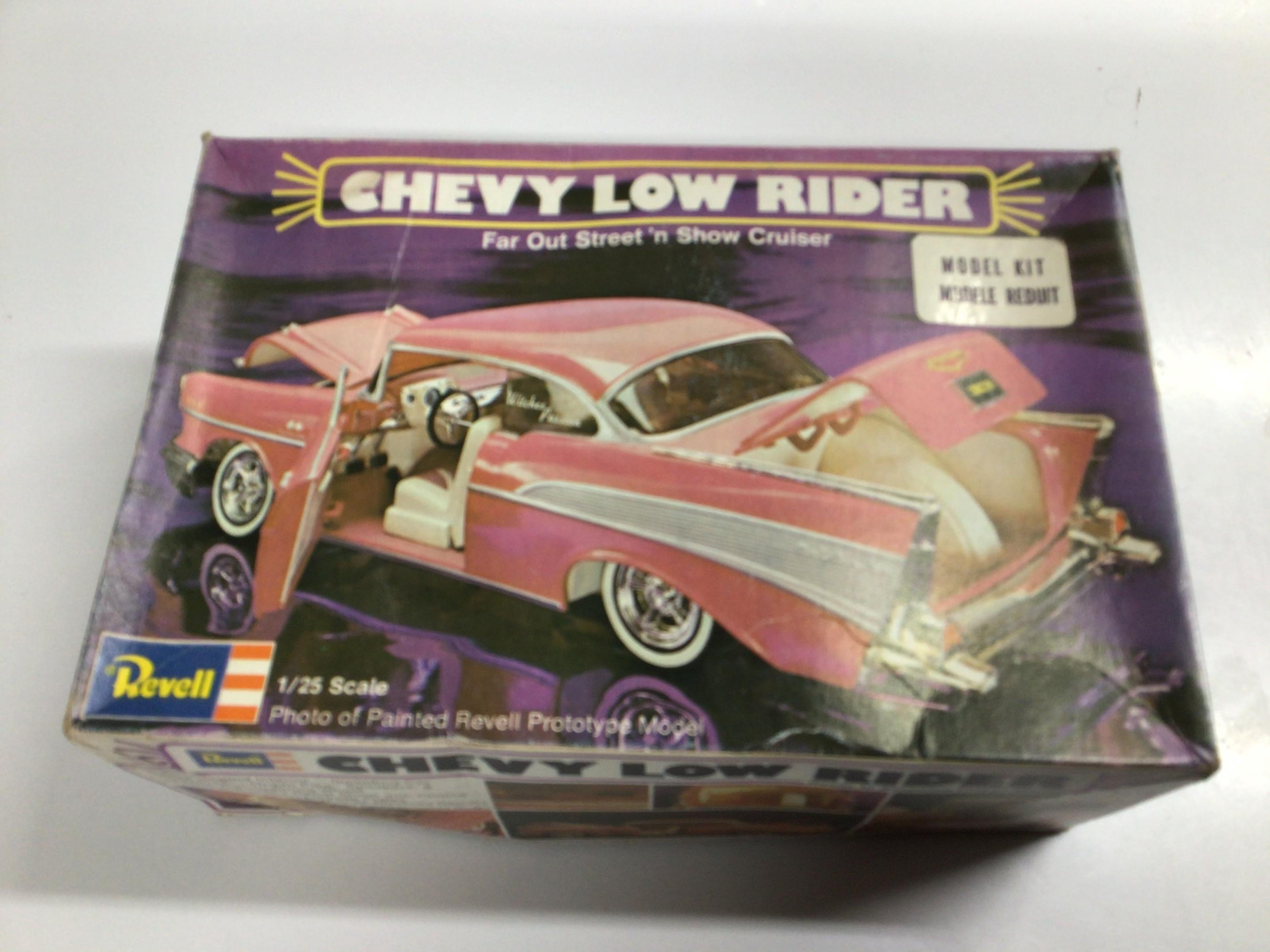

So...since this thread is about lousy ‘57s, how does this old kit compare accuracy wise? I searched this site via google and could not find pics of a built one. I gathered that the doors don’t fit proper or are finicky, and the plastic is brittle. One member said he built a few and had no issues with it.