-

Posts

5,194 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Bainford

-

Cool project. Good work so far.

-

What is your oldest unfinished W.I.P

Bainford replied to Sam I Am's topic in General Automotive Talk (Trucks and Cars)

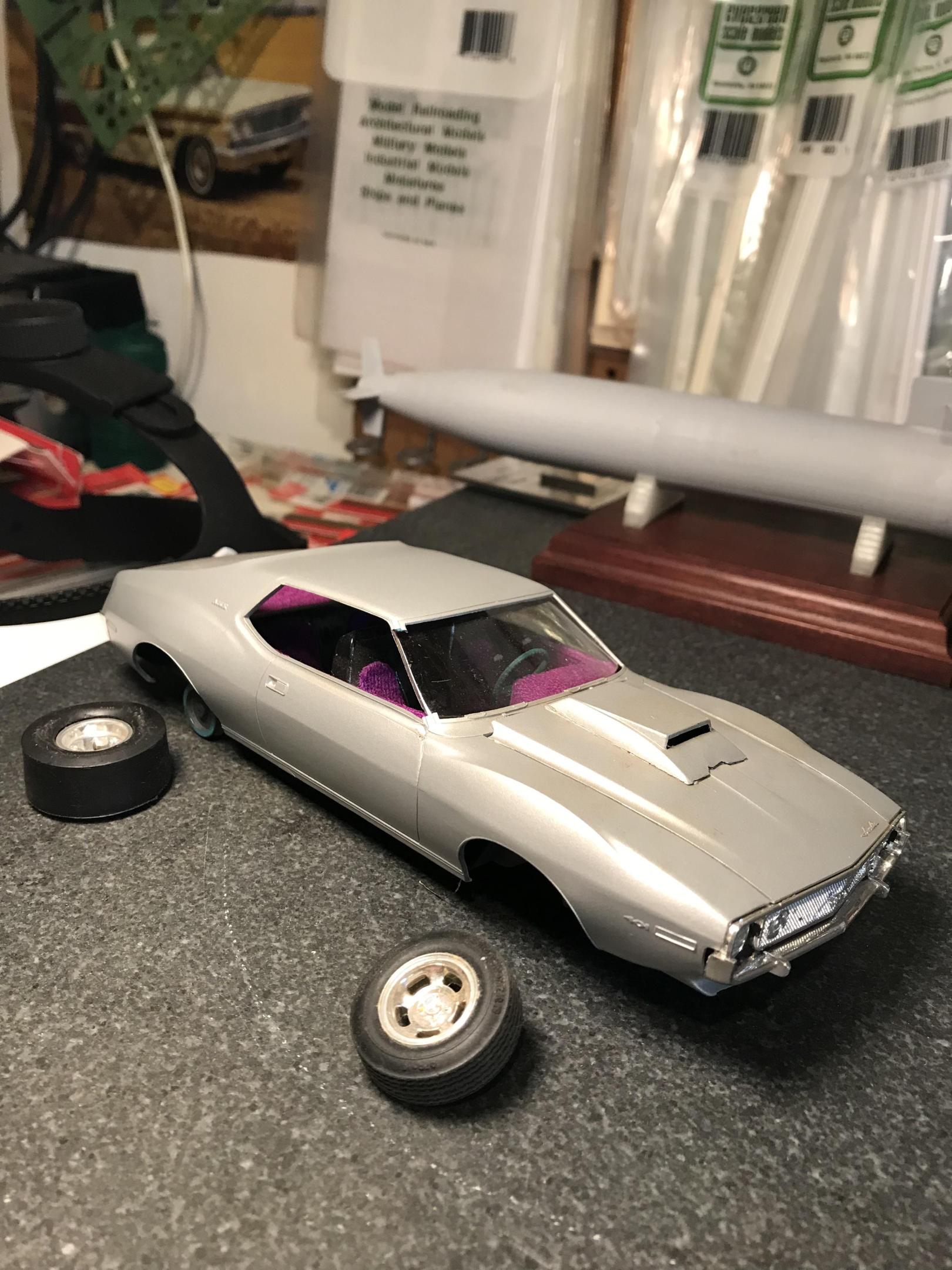

A JoHan Javelin, a JoHan Mustang funny car, and an MPC Pinto, coincidentally all started in 1984. The Pinto went back in the box when ambition out paced talent & knowledge in my attempt to scratch a four link rear suspension. The Javelin, because I didn’t like the direction it was going (your eyes don’t deceive you, that’s purple shag in the interior). I quit the Mustang because I couldn’t find any satisfactory decals (pre-Slixx era, of course). I see now its lost its engine somewhere along the way. -

Reminds me of when I was living in the Northwest Territories, going to work in morning with temps below -40. The tires on the truck wouldn’t lose their flat spots until I was almost there. It was particularly annoying when the flat spots all synced up.

-

I glue ‘em. The original reason was to ensure the wheels are straight and wobble free. Years later I began to employ the ‘flat spotted tire’ technique which, of course, necessitates glueing the wheels from rolling. I was in my late teens when I hit upon the idea of glueing the wheels solid, but it felt like cheating at the time. To satisfy myself that it wasn’t, I would build to make the wheels roll, then hit them with glue afterwards. No silly pretence nowadays, I just glue ‘em.

-

My favourite Mopar. Looks cool. Cool period stance. Nice clean details. Well done. A word of advice, if I may. A little black wash on the wheels would really wake them up. It can transform the look of the whole model. Cheers

-

Nice conversion. A lot of good work there. I imagine it’s not easy to stuff the large new-Camaro into the little old-Camaro body. Very cool!

-

1963 Lola GT

Bainford replied to Gramps46's topic in WIP: Other Racing: Road Racing, Land Speed Racers

The Lola is looking great, Gary. Coming along beautifully. -

1970 Pontiac Super Stocker

Bainford replied to Zippi's topic in WIP: Other Racing: Road Racing, Land Speed Racers

One of my favourite series of car kits. I grew up on a steady diet of asphalt late-models, and these MPC kits emulate them nicely. Looking forward to seeing this one come together. -

Welcome to the forum, Jim. The Comet is wicked cool. There is a lot of information on the site about working with resin. Any specific questions you may have, try a post in the 'Question & Answers section of the forum. Cheers.

-

3D Printed Wire Wheels

Bainford replied to MrObsessive's topic in Car Aftermarket / Resin / 3D Printed

Bill, that is some crazy impressive work. I continue to be blown away by what you and others have made possible with 3D printing. -

The engine bay really looks the business, Bill. Nicely done.

-

Very cool, Jim. Digging the wild paint. I am intrigued by the vinyl number on the window. Is this stuff a thin self-adhesive vinyl? Is it available in other colours, especially straight chrome-look without the colour tint? And did you make the number with a cricut, or something similar? I have a 70s stock car project I'm gathering stuff for, and have yet to find a solution for the chrome-look numbers on the doors and roof. I was aware of chrome-look adhesive vinyl, but figured it would be quite thick, but yours seems very thin. The cutting of the number looks very clean, too.

-

Impressive project.

-

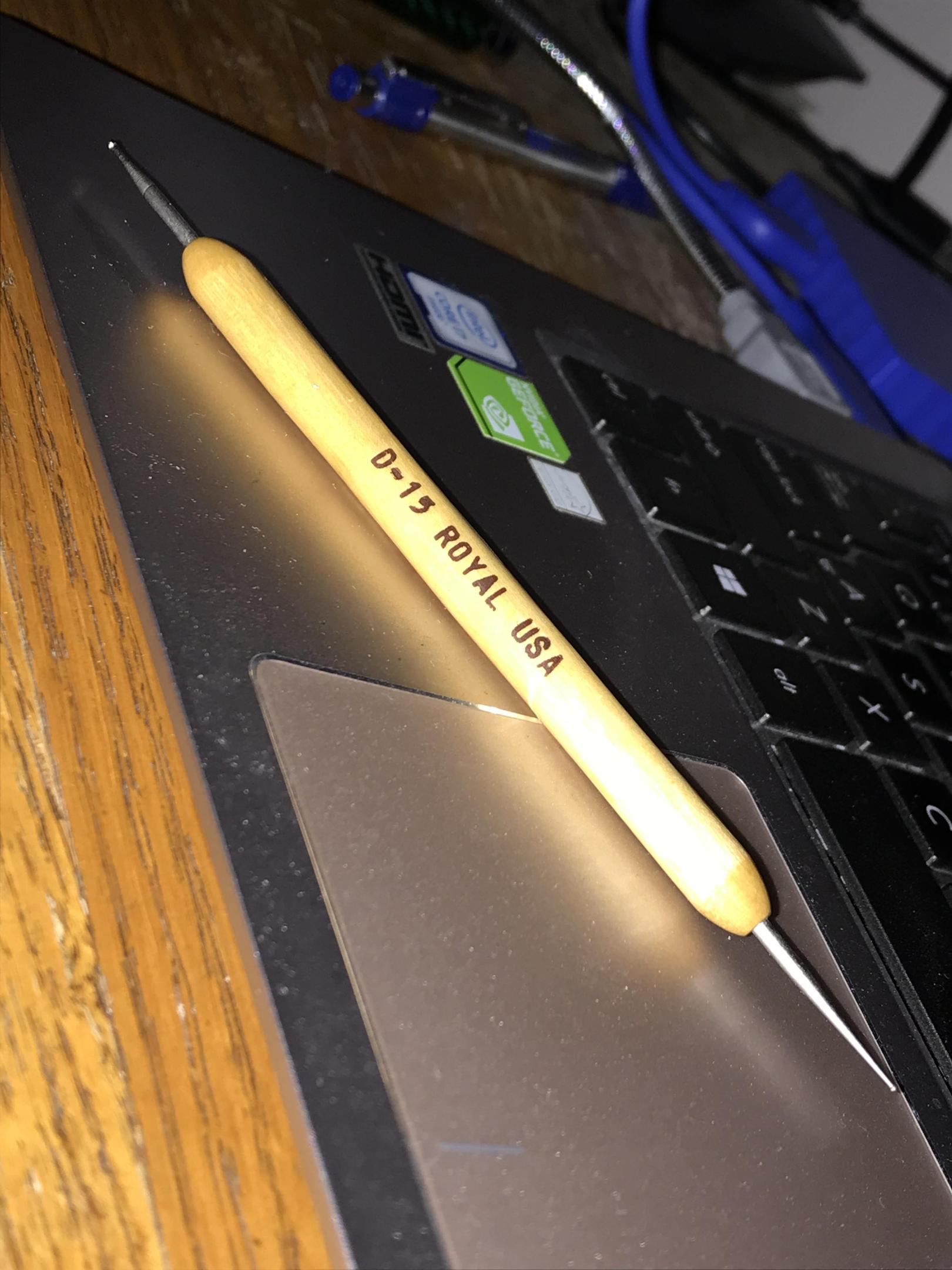

Cheers Gary. I have something similar to that, purchased at an art store. Actually, I unwittingly bought a second identical one a few years ago, so I have one I can dedicate as a paint/glue applicator.

-

Solder exhaust system advice needed

Bainford replied to Monty's topic in Model Building Questions and Answers

Like Greg says, solid core for sure, and be sure to use lead-free solder. CA or epoxy for glue. I use CA. For a stock sixties car, I would use 2 mm (.080") solder, which is equivalent to a 2 inch pipe. For a modified street car, go for the 2.5 mm. -

Great idea, Gary. The box trick looks very handy. What is the end of the finger nail stick like? Is it a brush of sorts?

-

Very nicely done, Lee. A beautiful build of an old and challenging kit. I attempted one in my teens but never finished it. I have another in the stash, and someday hope to conquer that kit. Yours is an inspiration.

-

1941 Chevrolet Panel Truck

Bainford replied to Sam I Am's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Cool project. The ‘41 looks great as a panel. Nice work on the floor. -

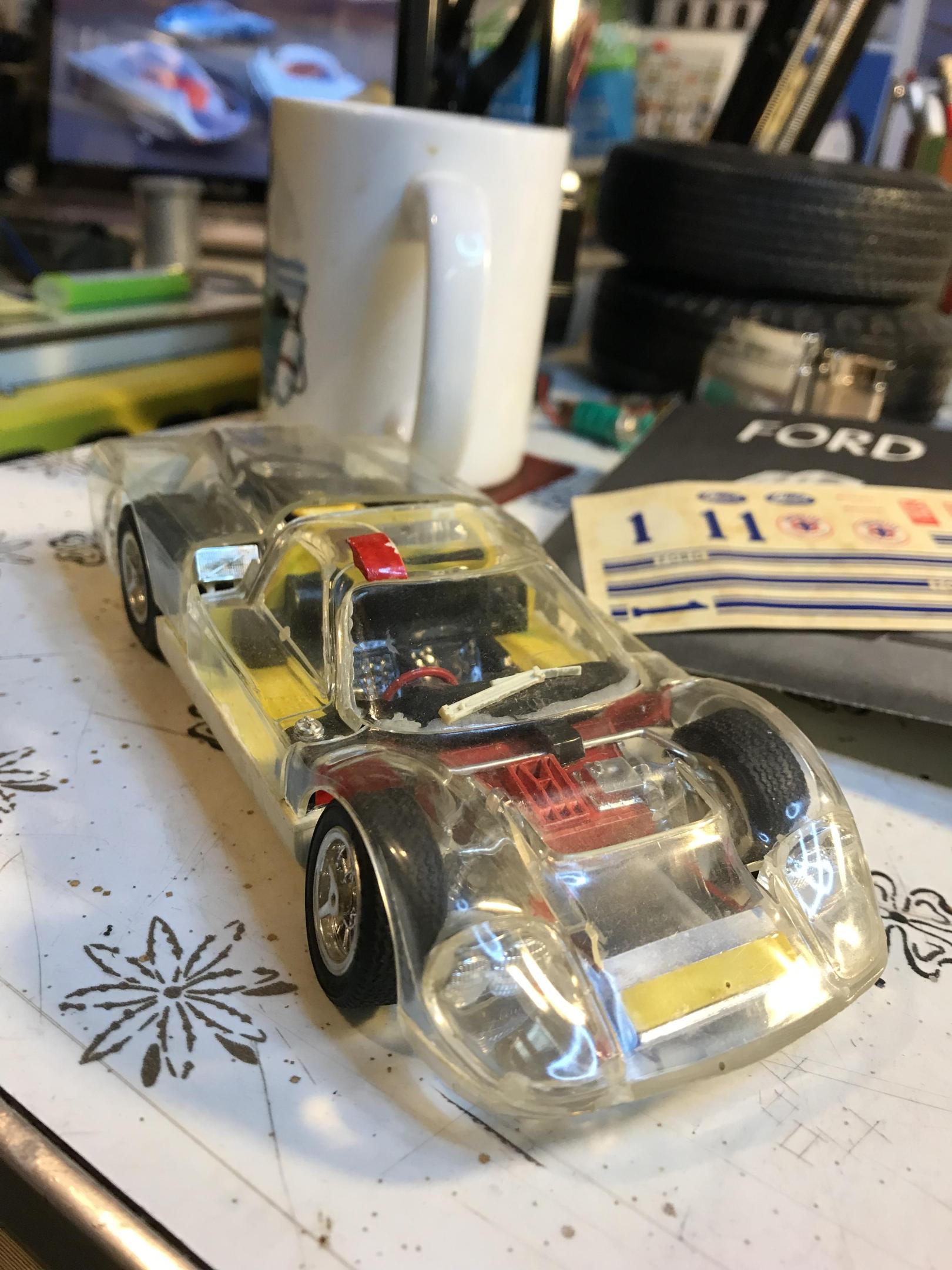

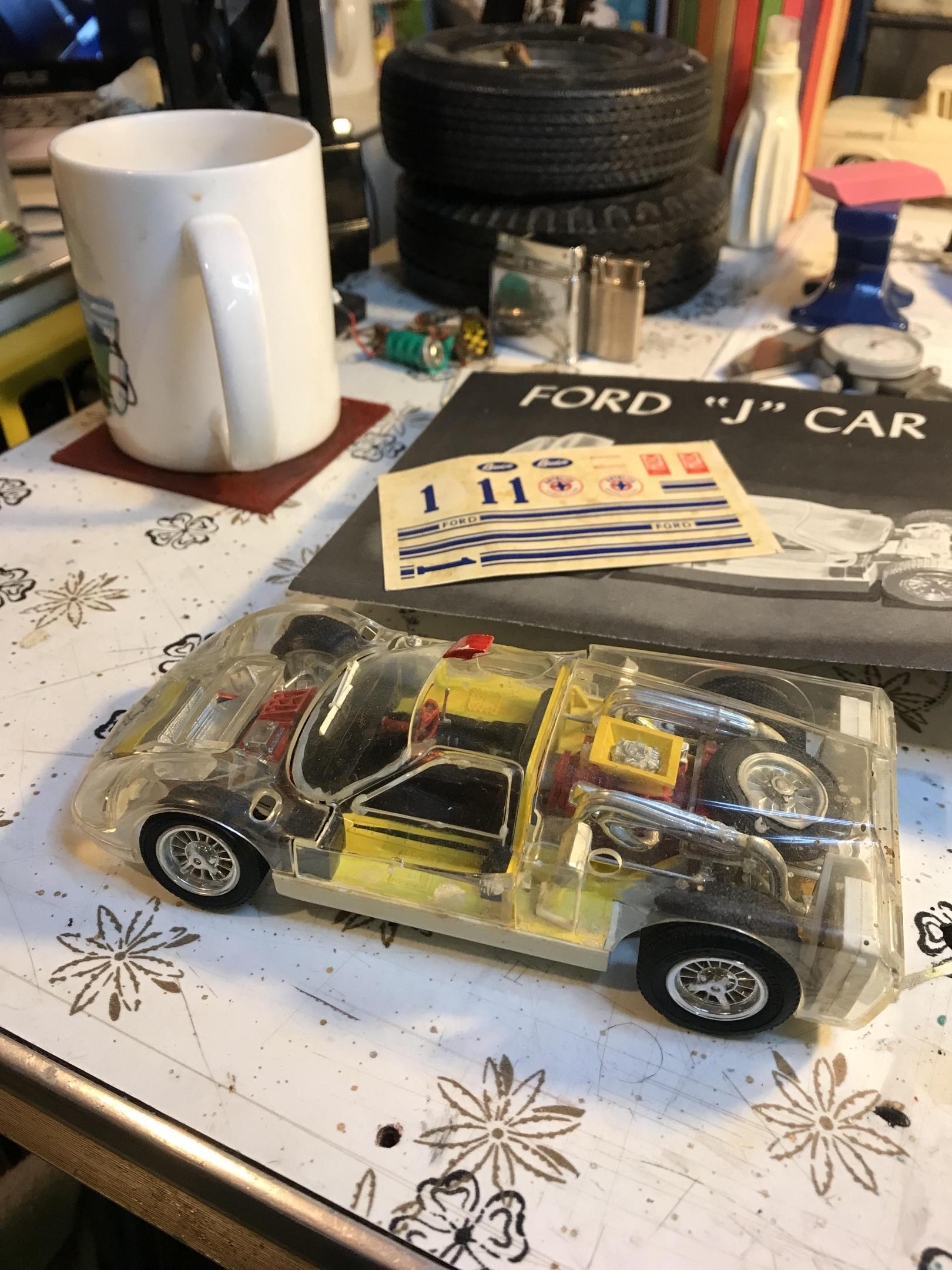

Ford J car

Bainford replied to 65slotcar's topic in 1:1 Reference Photos: Auto Shows, Personal vehicles (Cars and Trucks)

Cheers Rex. I didn't realise both front ends were provided in the kit. -

Nice little Pontiac, Ismael. Nice clean work in small scale.

-

Ford J car

Bainford replied to 65slotcar's topic in 1:1 Reference Photos: Auto Shows, Personal vehicles (Cars and Trucks)

Nice J Car, Rex. Beautiful. I didn’t realise the kits were released in both pickle fork nose and conventional nose. Mine is not the pickle fork version. I thought I read once that the MPC kits were available in both clear body and white. Is yours white body? This is one I got a few years ago in a box of built 60s & 70s kits. Instructions and decals too, though the decals are looking a little spotty. -

Thanks for that Jason. I just had a look. It would cost me $184 CDN to get it to my door. Unfortunately ordering kits in the US has become a no-go for many in Canada due to the exorbitant shipping costs of the last few years. Sites like ebay are pretty much off limits now, as everything is at least $40-$50 to ship (not to mention the hefty export charge ebay has taken upon themselves to charge everything coming to Canada). I think that inadvertently turned into a bit of a rant. Anyway, I will be keeping an eye out for one of these kits, though. The Citroen is a cool machine, and I've been anxious to try an Ebbro kit. Cheers.

-

'65 Shelby GT350...

Bainford replied to Mothersworry's topic in Other Racing: Road Racing, Salt Flat Racers

Very nice Shelby. Great original, mostly-unmodified look. Love it! -

The Sizzling Duck! Named, of course, for its blistering acceleration of 0-100 km/h in 54.5 seconds. Cool build of this interesting, limited production model. Nice clean work. You nailed the look. Well done.