-

Posts

3,949 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MeatMan

-

Mid-engine custom Corvair aka "Unsafe At Any Speed" :)

MeatMan replied to ea0863's topic in WIP: Model Cars

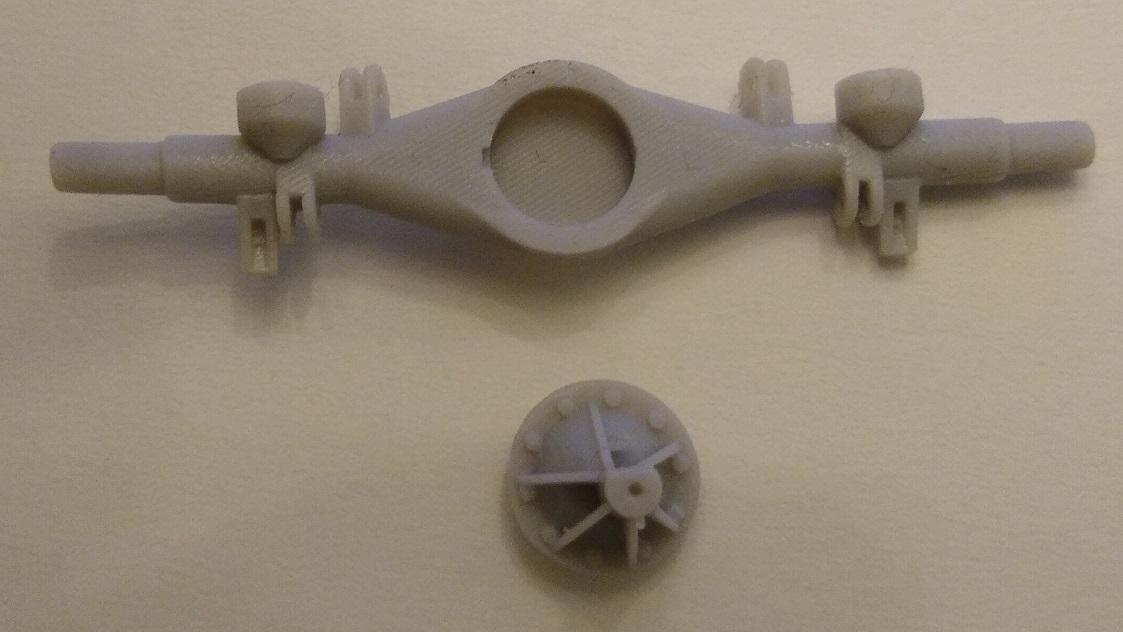

Very well done EA! I did one and tried to use that chassis but couldn't make it work. You aced it tho. I was trying to use a transaxle. I finished the build but botched the paint so its back in the drawer until I feel like fixing it. Here's pretty much where I stopped. -

My pleasure. and thanks for the compliments. I design stuff for myself and don't want to get into sales so why not help the cause!

-

Mine does as well. You have to play the game to get the best pricing.

-

Tamiya Subaru Impreza 1998 my 10th.

MeatMan replied to PatW's topic in Other Racing: Road Racing, Salt Flat Racers

Well done Pat! -

AMT '70s Short Body R.E. Dragster (05/22/2022)

MeatMan replied to Straightliner59's topic in WIP: Drag Racing Models

Nice project and fabrication work! -

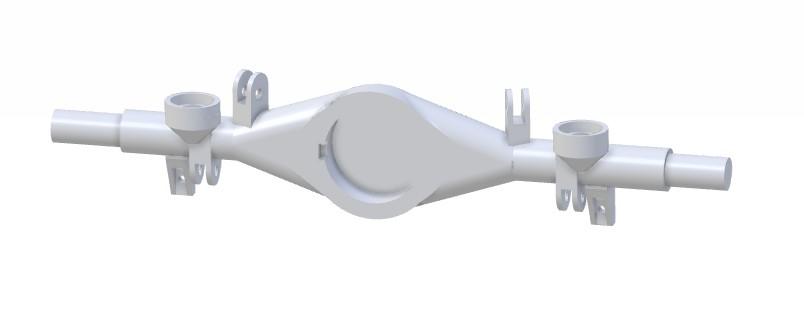

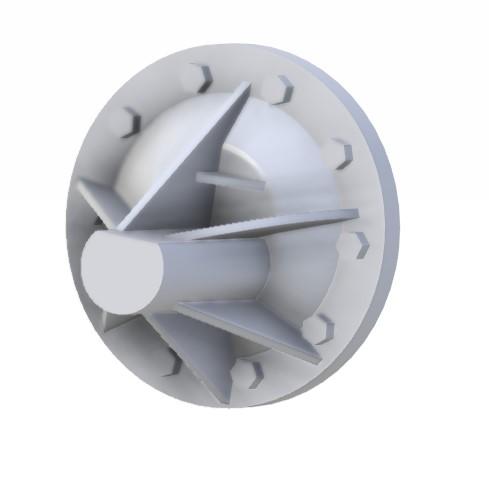

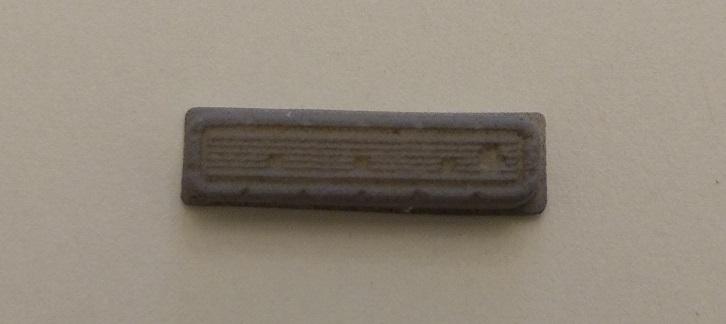

For those interested, I've added a couple of free 3D print files to my Cults account. https://cults3d.com/en/users/Meatman/creations BOP offset rear axle based on the 60 Catalina kit. SBC custom valve covers based on some Edelbrock covers I saw online.

-

Rough Terrain Freightliner

MeatMan replied to BIGTRUCK's topic in Model Trucks: Big Rigs and Heavy Equipment

Nicely done! -

Anyone ever stack in your 3D printer?

MeatMan replied to Oldmopars's topic in Car Aftermarket / Resin / 3D Printed

Interesting setup! I've never tried it but it certainly could work. One thing I would caution on is the fact that you are multiplying the load on the lowest layer of supports, especially the first ones that print. I would make them medium diameter. That of course may make them harder to remove, or clean up. -

Cool!

-

Well done! I'll have to give it a go.

-

Replacement windshield heat formed

MeatMan replied to Lovefordgalaxie's topic in Tips, Tricks, and Tutorials

I've seen other ways to do this but your post is simpler for this type of part. Thanks for the tutorial. -

Awesome work!

-

TinkerCad? Do you use it or other free 3D?

MeatMan replied to Oldmopars's topic in Model Building Questions and Answers

Good stuff! You're beyond me. I don't use TC anymore either, I bought Alibre Atom. I can't remember why I didn't want Fusion tho, but not sorry other than it has a larger user base and more vids on YT that help when you get stuck. -

Nice start! I like where you're going with it.

-

Nice!

-

The 2022 Cannonball Run Year of Birth Build Thread

MeatMan replied to disconovaman's topic in Community Builds

I put a Viper engine in a 56 Chrysler 300 a while back. I cut the crossmember down to allow the engine to sit lower, which req'd me to change the front suspension to a strut type coming up through the wheel wells. Might be an idea for you. -

Nice project! Great start.

-

1950 Chevy Dually Shop Truck

MeatMan replied to Zippi's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nice work! -

Posting another free file download. This is a C-cab truck and frame that I wasn't going to post originally until I built it myself but I have a health issue I'm dealing with and realized that I have more projects than time. I've printed both in both FDM and resin and they print well. I'm doing a wild custom for mine if I ever get to it. I hope someone will print and build one to post. https://cults3d.com/en/3d-model/various/c-cab-truck-frame

-

Yeah, that's pretty rough. I've seen some vids where people coat their printed items in resin and sit it out in the sun to cure. It fills a lot of the roughness on the surface. Tho they usually show using a brush, I tried it using a little spray bottle and found that it works but you can't put it on thick or it will fill detail. For a body tho it might be the ticket. if you know someone with a 3D printer they will have some leftover resin that you may be able to get.

-

3D Printing Storefront Directory

MeatMan replied to Mr. Metallic's topic in Car Aftermarket / Resin / 3D Printed

Well, there are places that will print a file you buy elsewhere, so even tho you don't have a printer you can buy a file and have it printed. -

Yes, very!