-

Posts

10,231 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

Smooth-On, Smooth Cast 305. Seven minute pot life and 30 min. cure time. I am pleased with the results since I don’t have a vacuum chamber or pressure pot!? There were a few bubbles, but I stirred most of them out with a toothpick after pouring it in the mold. It is clear until it starts to set. I did about 10 rims plus all that with 2 oz. of resin and still had some leftover. The rally rims came out beautiful!?

-

Most Modern Ford Automatic?

NOBLNG replied to Plowboy's topic in Model Building Questions and Answers

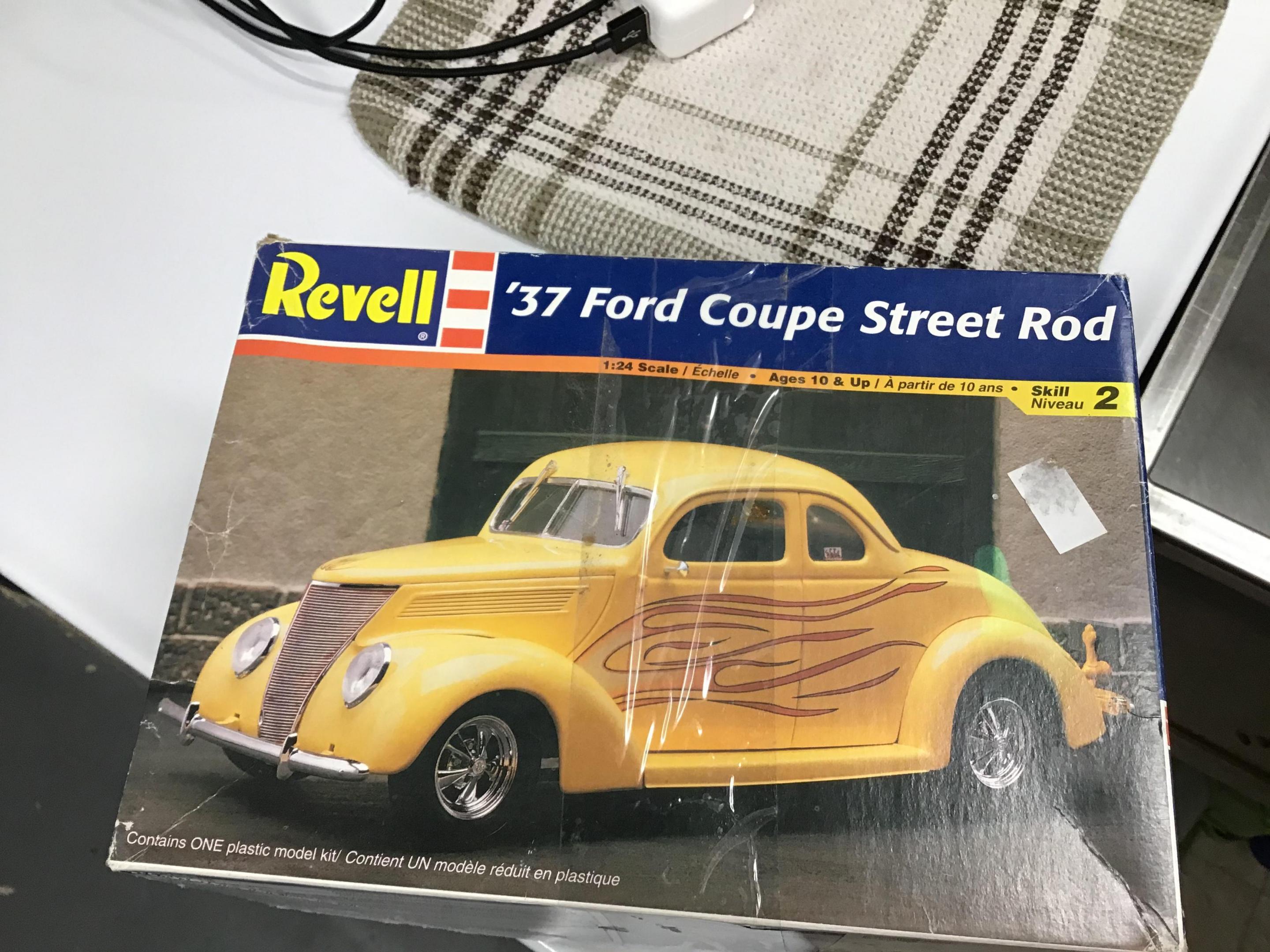

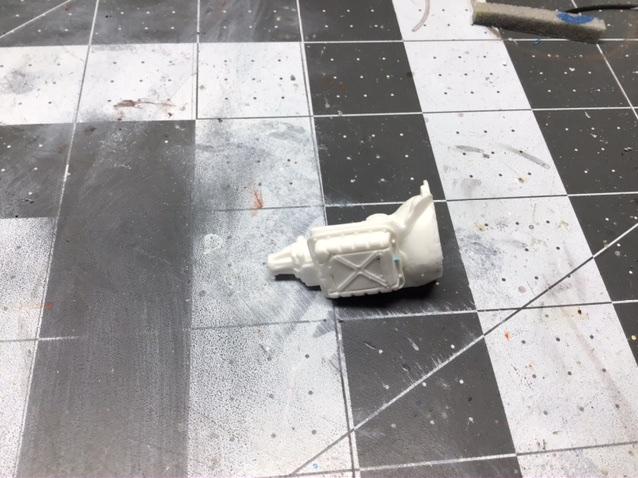

I’m not up on my Fords, but this kit has a decent 700R4. I hacked it off the engine which wasn’t so good! 1/24th though. -

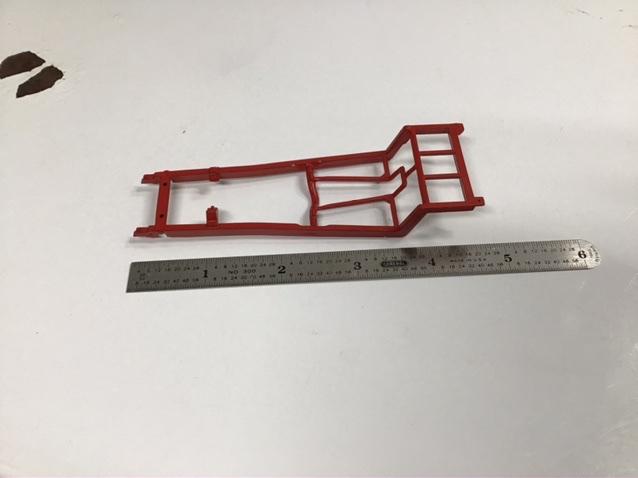

Thanks. That looks like a cool model. Too bad all I have is the frame.☹️ It was in with a kit I bought at a flea market.

-

Anyone know what this could be from? I know that’s a stupid question on this board....of coarse someone will! ? Thanks, Greg.

-

Looks good. That clear coat sure makes a difference. I love your body dolly there.

-

Very nice! I like the way the hub caps, trim rings and valve covers are done with matching paint. What paint did you use on the seat?

-

29 Window VW/Porsche Microbus

NOBLNG replied to 89AKurt's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

I agree! The lengths Kurt went to, to get this project where it is are amazing. Far, far more diligence than I have. And it looks fabulous to boot! -

TJeepster

NOBLNG replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I know what you mean about the frustration! I have at least 3 builds going on at the same time so I can walk away when needed. this is my first and about the fourth attempt at a rear drive shaft. I am happy with the brass one. Thanks to Dennis for the idea! -

Thanks everyone. If the sun ever pops out here, I will get An outdoor pic.

-

That is sacrilegious putting a Dodge engine in a Pontiac! LOL?. Got any more pics?

-

Custom grille for rat rod or 60's show rod

NOBLNG replied to Alan Barton's topic in Tips, Tricks, and Tutorials

Me too. It would go perfect on a model idea I have cooking in my head! -

Pete W. (peteski) just posted a link in my thread to this site. They have some cone sanding sticks. https://www.flex-i-file.com/

-

They have a lot of neat stuff on that site. Yes this would work similar to those files, but you can get more wrap- around with the manual method. The flexible sanding film would work better on inside curves for sure. It doesn’t clog up very easily either.

-

I mostly use Tamiya extra thin quick set (because I’m a very impatient person), and I like the little brush on the lid. I have found it very “aggressive”. I mean that if I apply it to a very thin part that is under any stress at all., the part will snap. Example: trying to make a sharp curve with small half-round styrene to a body for a vinyl top molding.

-

Some of you old hats may know this already, but I discovered this trick while sanding a differential that I modified. It works great on exhaust tubing seam lines too. Cut a 6” long or so narrow strip of your favourite sandpaper. Clamp one end solid somehow and hold onto the other end. Hold the part being sanded in your other hand and work it up and down the strip. You can vary the tension on the paper and also the angle of the paper from nearly flat to a 180 degree wrap. Works great for blending things back to round after scraping mold lines too!

-

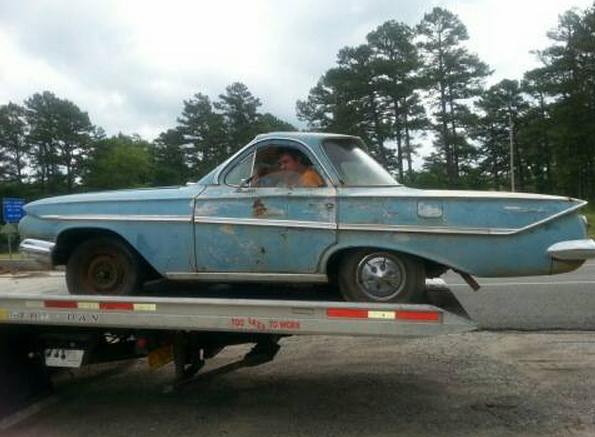

Woe that is a far cry from what you started with!

-

Wing or foil shaped styrene rod

NOBLNG replied to Scott Colmer's topic in Model Building Questions and Answers