-

Posts

10,236 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

It doesn’t look like you did. I think that would have destroyed the upper hinge? All your pillars seem to line up nicely! Nice sectioning job too! Any finished pics of it Mike?

-

Looks like a nice clean chop to me! ? I too suffer from a lack of a concrete plan for most of my builds. Looking forward to seeing the developments.?

-

This sounds like a good rule of thumb. I think my chop was 3” or 3-1/2”. I’m not a big fan of the “hammered” look…I mostly want to get rid of the greenhouse look. Thx.

-

Excellent work all around. It looks much sleeker than original. Those pins for dash knobs is a terrific idea…consider it stolen!?

-

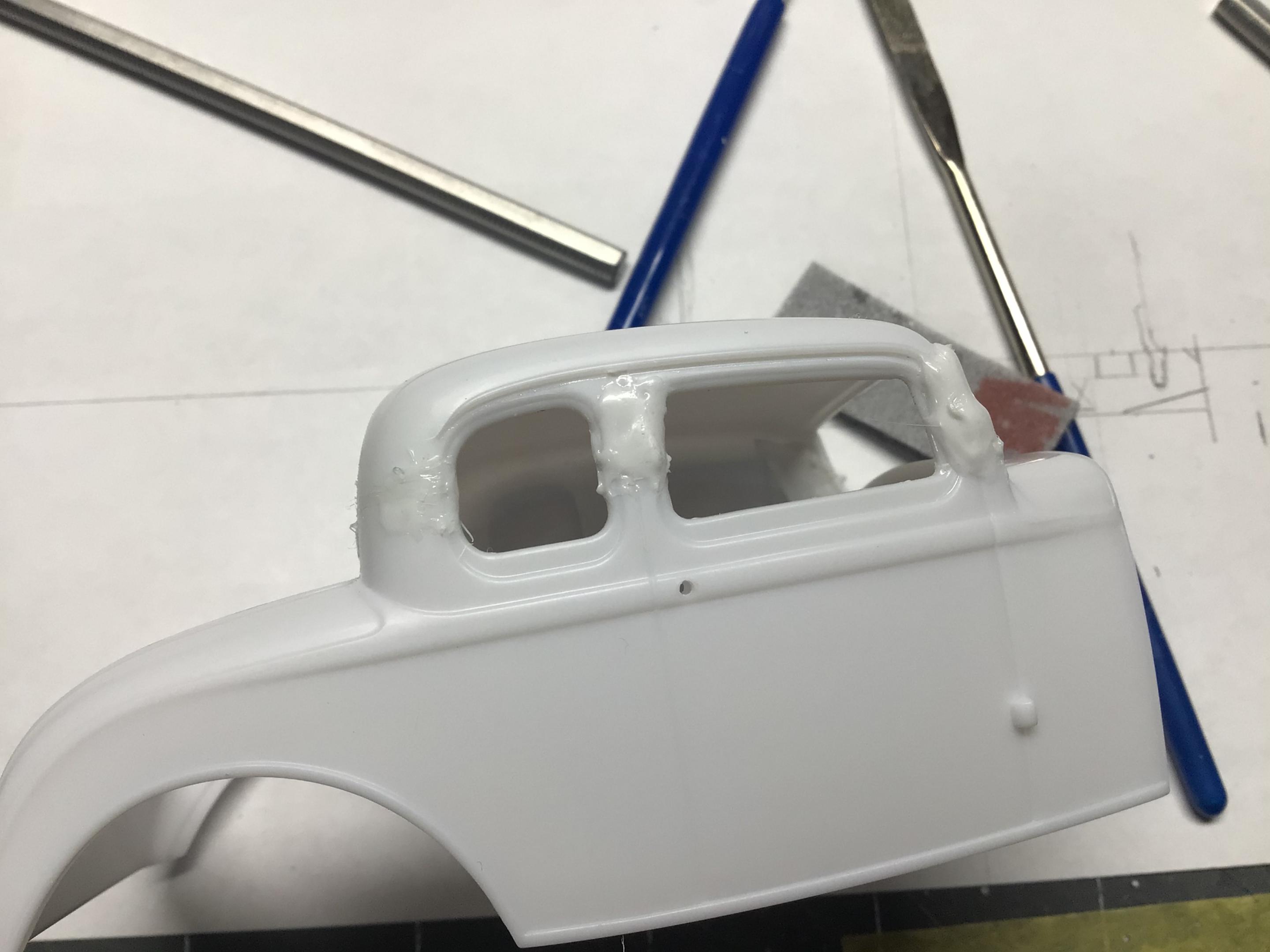

Thanks. This was my first ever chop and I aligned the rear section because I figured it would take a lot more filler to blend than the center post would. Next time I think I will cut just under the drip rail and move the top half of the B pillar back into alignment. Thanks, I am happy with the results, but I did slather on a bunch of sprue glue to blend and reshape the A pillar. My next chop will likely be the AMT ‘32 Vicky. I figure with careful cutting and filing the removed piece should fit back in snuggly with very little filler required.

-

When I chopped this ‘32 you can see how I tackled the A pillar. I have seen other chops with a section removed from the mid point as well. The problem I had was the huge mis-alignment that required leaning the top section foward and the lower section back to re-align them….which makes three cuts. I was not about to lengthen the roof! ? I figure on my next one, I will cut out the entire A pillar and then shorten and file the two ends to match the cut angles on the body and roof. Has anyone done it this way, or have a better idea yet?

-

Yeah, or how does the spider not get electrocuted while making that connection?

-

Nice detailing Dave. The dash an interior look great!?

-

What if monster truck

NOBLNG replied to majel's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nice pair of Monster trucks you’ve built!? -

Very nice clean looking build! I like it!?

-

Sorry Hot Wheels......not seeing the point of this

NOBLNG replied to HomerS's topic in The Off-Topic Lounge

This just once again proves in my mind that a LOT of people have WAY too much money! ? If someone has a spare $69 million laying around to purchase something like that…..??? -

Can one of you post a pic of it with a recognizable paint bottle mounted in it? I imagine the bottle is mounted on it’s side and the thing oscillates? Thx!

-

Hacksaws are designed to cut metal but will hack just about anything apart.? That one looks like a particularly cheap example. You could use one if that is all you had, but if you have to purchase one…I wouldn’t! These will do a far finer job and a very worthwhile investment if you plan on doing more custom modifications in the future.

-

AMT ‘89 Chevy /drag boat Combo GSeeds

NOBLNG replied to gseeds's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nice pair! Beautiful work on the paint!? -

65 Chevy Stepside

NOBLNG replied to bluestringer's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Looks pretty good to me!? I too fairly recently got back into the hobby. I just try to improve slightly or try something new on each one. -

Revell 1957 Cadillac 4 door made into a convertible.

NOBLNG replied to carbuilder1950's topic in Model Cars

Well you certainly have a way with Bling David! This turned out beautifully!? -

65 Chevy Stepside

NOBLNG replied to bluestringer's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nice job! That color looks great on it!? -

Awesome! Love the wiring harness idea!?

-

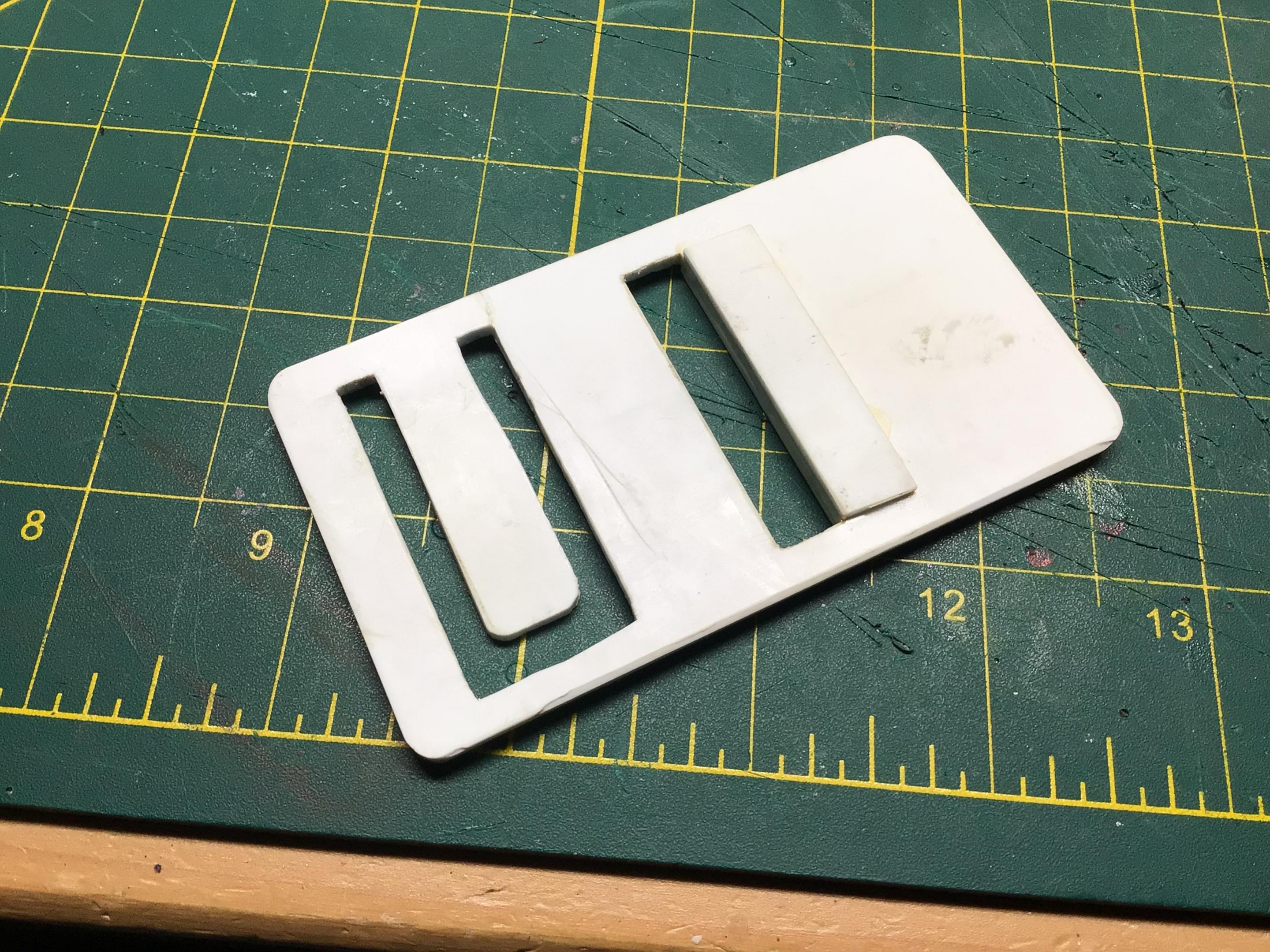

I made this clip for holding the RV fridge door open while in storage. I lost one a couple of years ago.