-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Bainford

-

Old skool! Very cool little dragster. Nicely done.

-

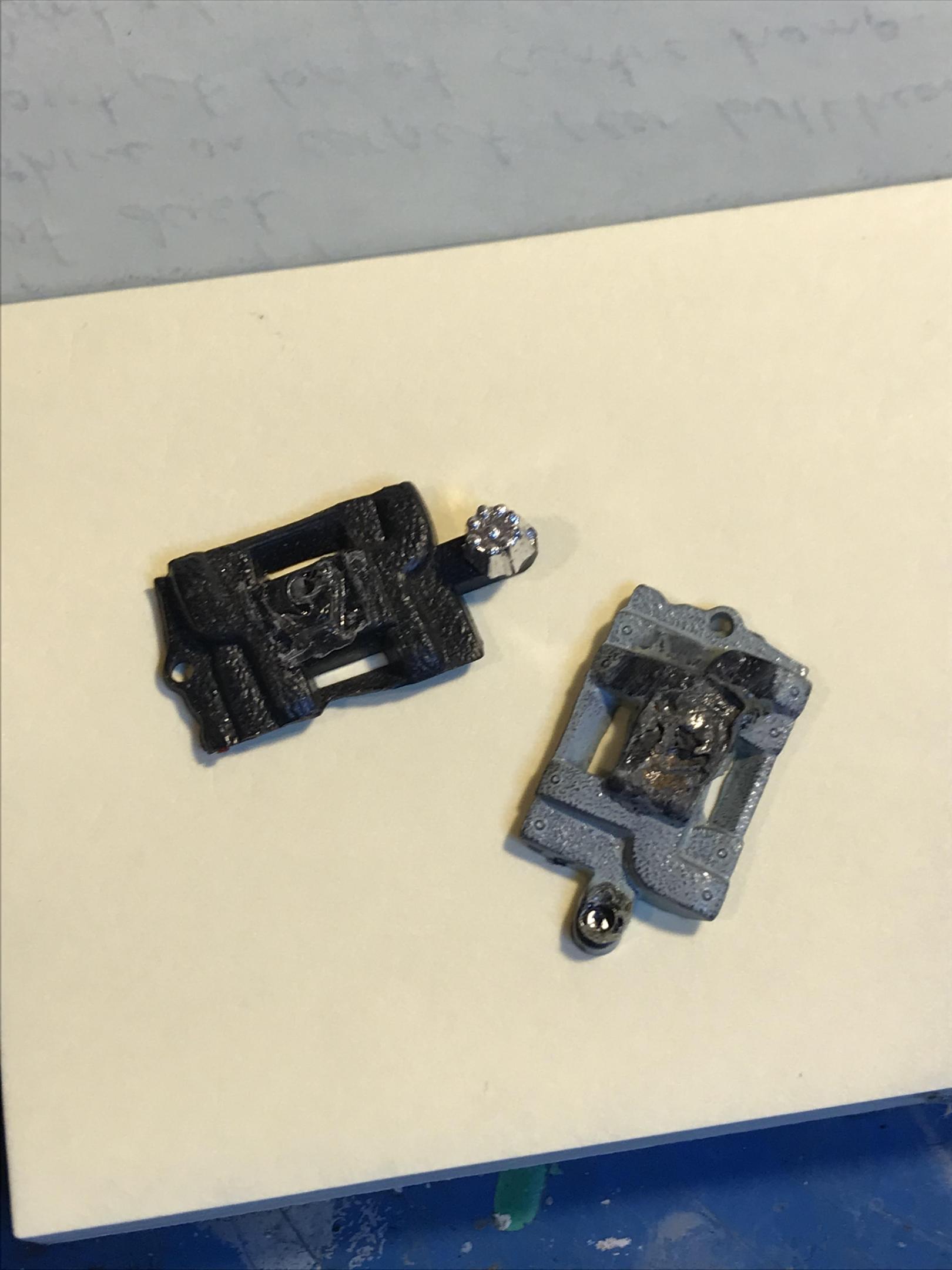

Stellar build, Mike. It is a real display of tenacity to get through this kit to completion. You've done a heck of a job with it, and the extra detailing is certainly icing on the cake. This must be one of the nicest builds ever done of this kit. My hat is off to you, sir. Very well done. I must also thank you for the tip on the metal ferrules. Seeing them in your build thread, they seemed to hold promise, so I ordered some from Amazon. I am really impressed with the quality and look of the ferrules. The flared edge is clean and square, the tube is seamless, and the colour is just right to replicate aluminum tubes. And a package contains a few hundred ferrules in five different sizes for a very reasonable cost. Much cheaper than machined stacks, and very nearly as nice. Baomain AWG 22/20 / 18/16 / 14 Long: 8mm Wire Copper Crimp Connector Non Insulated Ferrule Pin Cord End Terminal 500pcs: Amazon.com: Industrial & Scientific

-

Very cool creation. Lots of imagination on display, here. Very nicely done.

-

Welcome to the forum, Mascari. Nice builds you have there. I think you'll find yourself right at home, here.

-

Testors Aluminum plate.

Bainford replied to Mike 1017's topic in Model Building Questions and Answers

Thanks Steve. You are absolutely right, of course. I myself have used silver paint to good effect as a barrier. Just so there is no confusion though, my comments above apply specifically to Model Master Aluminum Plate Metallizer and its use as a general primer, a method supposedly developed by Mr. Yost. Not having actually seen Don's videos or read his own account on this method, I wonder if there is more to it. Or, perhaps he intended this method to be used only as a barrier/primer. I really don't know, but I have known a number of builders who, after having heard Don's advice, used aluminum plate as a general-use primer. It sounds like an advanced method, perhaps even experimental, and for most modellers I would recommend sticking with a known good primer. -

Very cool, Lee. I really dig this build. That's a great looking Duster.

-

Save on sandpaper AND have precise control.

Bainford replied to Bills72sj's topic in Tips, Tricks, and Tutorials

Very nice, Bill. This is a great tip, and I can see adaptations for specific sanding situations. Thanks for sharing. -

Chrysler kit car question

Bainford replied to robdebie's topic in Model Building Questions and Answers

Yes it will, as I am one. One of my favourite local short-track heroes of the 70s drove a Mopar kit-car to great effect all over eastern Canada. I’ve gathered a couple kits to build a model of it, been following this thread with interest. -

1964 Pontiac 4 Barrel Intake Manifold.

Bainford replied to StevenGuthmiller's topic in Model Building Questions and Answers

Oh yeah! That looks great. Sometimes it’s a matter of finding the manifold hiding in the blob of plastic. -

Sweet looking '55. The '55 is my favourite of the tri 5 Chevys, and your build brings out its finer points nicely. Well done.

-

Testors Aluminum plate.

Bainford replied to Mike 1017's topic in Model Building Questions and Answers

Actually Pete, it is a recommendation of known modeller. I think it was Don Yost (and someone please correct me if it was not him). I expect that this is the source of Michael's method. Back on the SA forum a fellow was using the same method, and experienced the same problems; all the paint ripped off with masking tape. It seems a very odd choice to me. I believe the idea is that Model Master (Testors) aluminum plate Metalizer hides absolutely no detail at all, and it is exceptionally revealing of defects. But the surface finish of dried aluminum plate is somewhat loose and dusty, and for that reason it seems to me it would make a poor primer. I must say though, that I have not seen Don's painting videos or read any painting posts he may have made, so I don't know his reasoning, or if he employs a special method of application to make it work, or whatever. There may be more to the story. -

Testors Aluminum plate.

Bainford replied to Mike 1017's topic in Model Building Questions and Answers

It's not the tape, It's the aluminum plate as primer. It has an almost dusty finish, and I wouldn't expect anything to stick to it. Besides, it's out of production and highly sought after for its intended purpose as an aluminum finish, for which it is unmatched. It would be a shame to waste it as primer. Get a trusted primer and this problem will go away. -

Nice photos, thanks for posting. These are the best up-close-and-personal photos I've seen of a Powell. Really dig the fishing rod stowage. I always thought that was a rather innovative feature for such a basic vehicle. Years ago I was going to scratch build one of these, figuring its straight panels and lack of compound curves would make for a fun, first-time full body scratch build.

-

A REALLY rear engine Corvair - unsafe at any depth!

Bainford replied to mr moto's topic in Model Cars

That is too cool! Beautifully built. I love it. -

That's looking great. Nice work.

-

Nice improvising, Ulf. Good looking Moon caps. I do something similar with a bench top drill press. It's a bit of a pain working vertically, but my turnings are pretty simple, and it gets the job done. One of these years I'll pull the trigger on a proper lathe.

-

1964 Pontiac 4 Barrel Intake Manifold.

Bainford replied to StevenGuthmiller's topic in Model Building Questions and Answers

Looks like the Polar Lights is the winner of that lot. Since I had a couple nearby, I checked out the MPC 70s Firebird. Lacks fidelity. -

Very cool little model, and very cool subject. Nicely done. Such an interesting machine from the heady, early days of the automobile. Bet she handles great.

-

62 Plymouth Station Wagon: Mighty Mopars Update

Bainford replied to BobbyG's topic in WIP: Model Cars

That is looking great! Quite an extensive conversion. Everything looks right. It’s going to be cool. -

Johan ‘70 Cadillac ElDorado pro touring (low and aggressive)

Bainford replied to Steve H's topic in WIP: Model Cars

Cool project. I like your vision. This will be a fun build.- 220 replies

-

- johan

- pro touring

-

(and 1 more)

Tagged with:

-

Your project is really shaping up well. It strongly evokes some of the crazy configurations that cropped up in the 50s/60s. The engine looks good with the variety of shades/textures used for the various components, and your plug boot solution looks great. Very cool project. Cool! What's he building? Has he posted a build thread?

-

How to create tiny silver rings

Bainford replied to Russell C's topic in Tips, Tricks, and Tutorials

Greg, I think you may have hit upon the potential for an excellent idea here. It is certainly worth some experimentation. I've devised and tested nearly a dozen methods and techniques for cleanly punching or cutting out small round discs. A couple ideas show small promise, but lack consistency. It's a problem I am keen to solve, and I think there may be potential in your suggestion. I'm picturing two drill gauges clamped together with the material to be punched sandwiched in the middle. The two gauges can be aligned with a couple of drill bits. The gauges will need a good, square edge at the 'die' edge, which can be accomplished with some lapping of the gauge on a flat surface, if necessary. The drill bit shank (the punch) can be ground at an angle, keeping the edge sharp, to facilitate clean cutting of the disc. Some experimentation is in order. I'm going to keep an eye out for a couple of hardened drill gauges. -

Great tip, Steve. Cheers.

-

Italeri Bugatti 35B 1/12

Bainford replied to maysula's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Sweet kit, and your build is looking great. Nice detailing and weathering. Your copper piping looks very neatly done.