-

Posts

10,233 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

55 Chevy

NOBLNG replied to avidinha's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

This is shaping up real nicely Andrew. I missed it the first go round...glad you’re back on it! -

Wow! Pretty darn cool! It should be stunning when you get some primer and paint on it.?

- 64 replies

-

- scratch build

- amg

-

(and 2 more)

Tagged with:

-

Canyonlands junk cars - diorama idea

NOBLNG replied to 89AKurt's topic in General Automotive Talk (Trucks and Cars)

Yeah! That looks cool. I think that could be somewhere in Utah? -

I agree...old stock. The stuff I have oozes out of the tube the instant I remove the cap and is fairly runny. I very rarely use it, but it does come in handy for certain applications. Like styrene joints that don’t fit tight enough for liquid cement and have to be precariously positioned. Epoxy would be my alternate choice for these joints. CA sometimes sets before the part is properly positioned. My biggest issue with it is trying to keep the strings off everything else.

-

And how would they know that they were Canadian unless they were caught?

-

In line 6 cylinder engines, what kits have them?

NOBLNG replied to Hondo's topic in General Automotive Talk (Trucks and Cars)

I would think that it is definitely a straight six cover? From what kit I have no idea. -

-

It’s 1 degree C here right now (33.8F) and supposed to get to 5C (41F) later today.?

-

Nice detailing on that engine!?

-

‘54 Willys P/U

NOBLNG replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

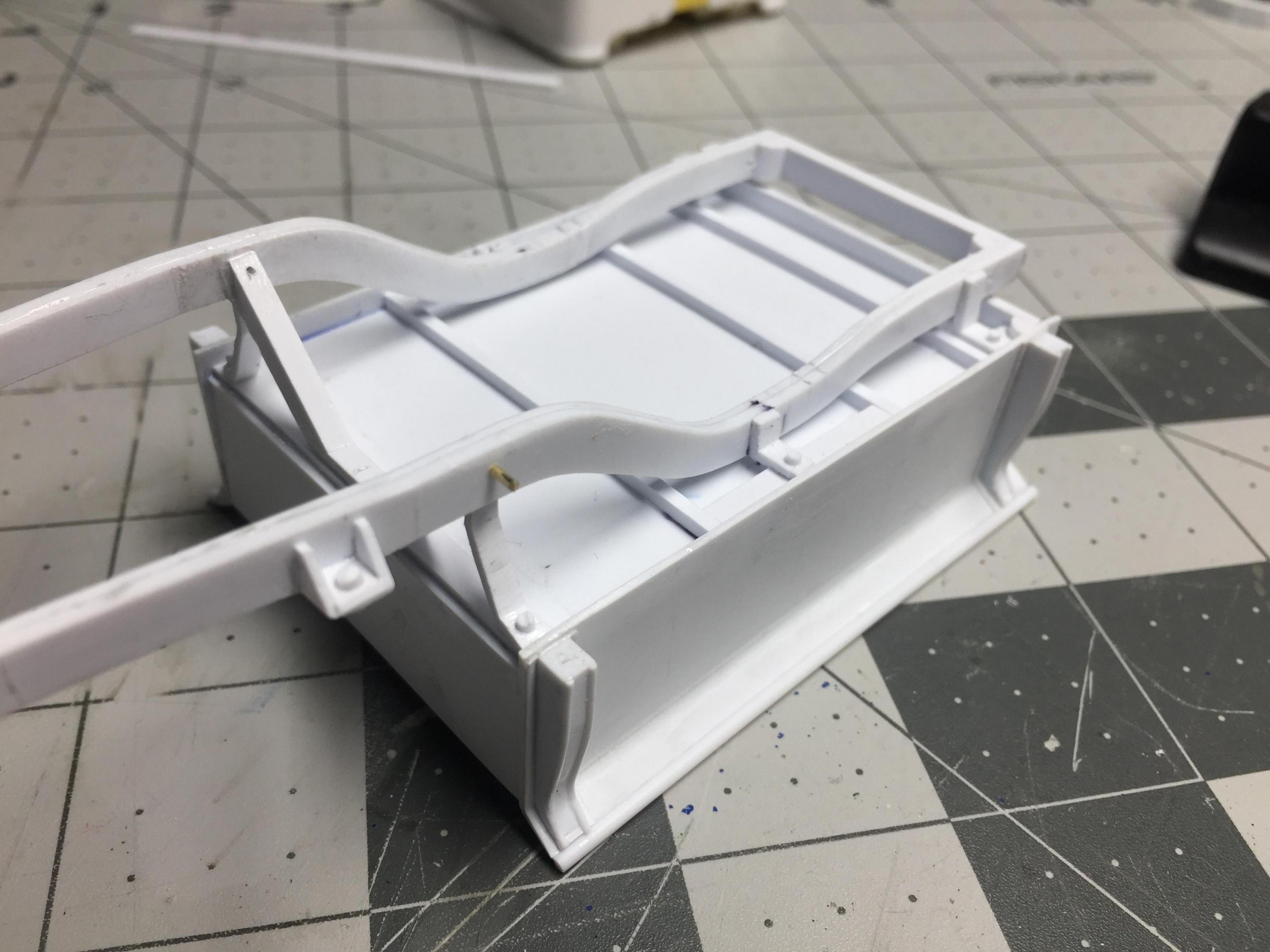

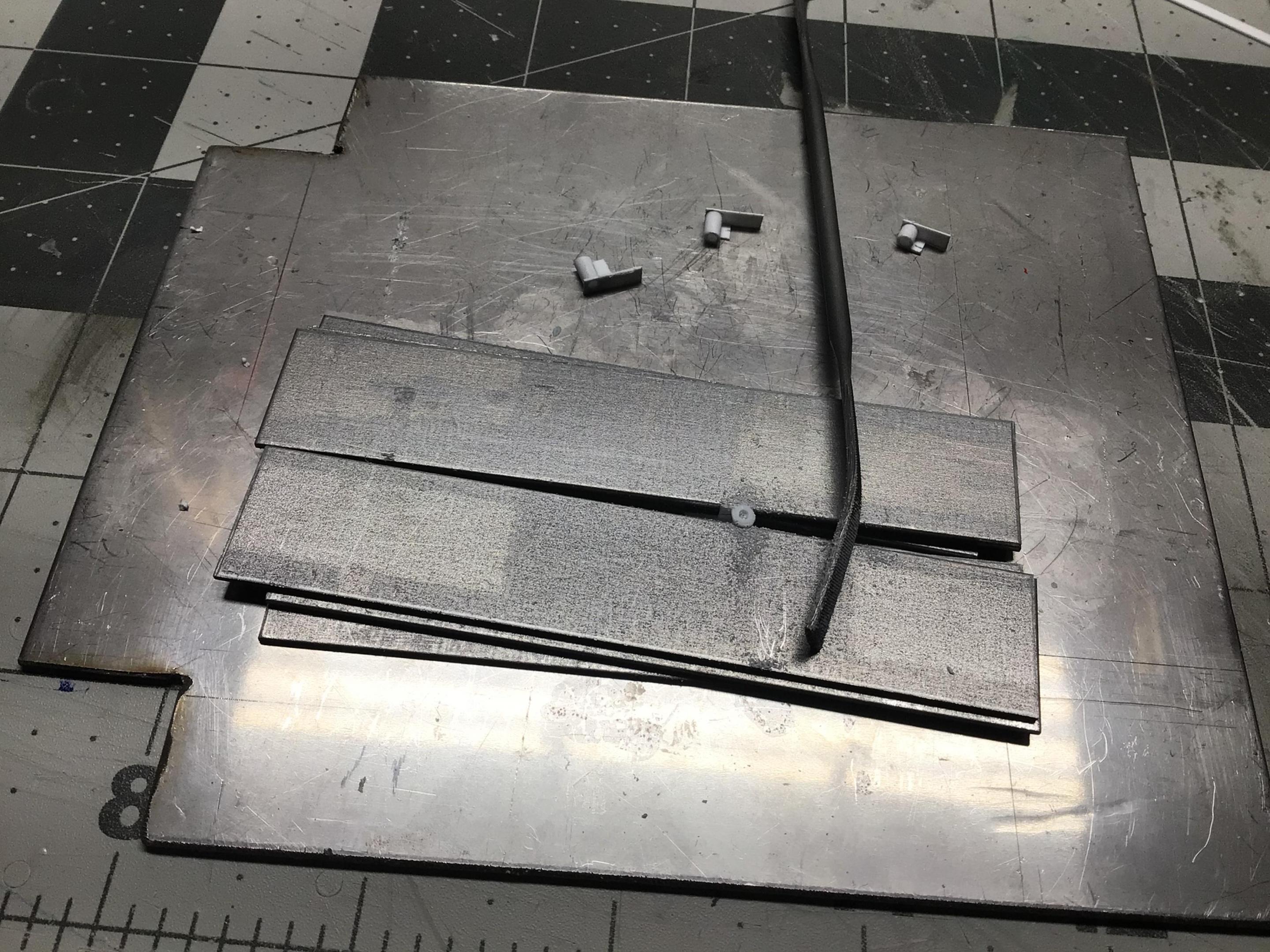

I’ve got the box mounts done using .050” styrene for locating pins. I also got a start on some more realistic shackles. They are .093” evergreen tube and .015” styrene sheet. I have some .038” metal plates (x3=.114”) that I stacked to file the shackles down to width to use with .100” wide springs. Ive used two chunks of 1/4” keystock to press parts together nice and square while the glue sets. Once they are dry they will get filed to shape. -

Uuh. Unless you’re planning on leaving the trunk lid off... I think you’re in the wrong section. Not that I don’t appreciate the traffic here. LOL!?

-

The Ugliest Corvette Ever?

NOBLNG replied to stavanzer's topic in General Automotive Talk (Trucks and Cars)

He should at least have all of his tools and equipment confiscated, and be banned from working on vehicles for life.? -

Scratch built/aftermarket big rig rear fenders

NOBLNG replied to wayne00's topic in Tips, Tricks, and Tutorials

-

You’re welcome. Anything you want to search on here... go to google and type in “site:modelcarsmag.com __________” and you will get results.

-

https://www.google.ca/search?client=safari&channel=ipad_bm&source=hp&ei=v1QwYKy2FefV5gL73Y9g&iflsig=AINFCbYAAAAAYDBiz6UOg0ISxbiiCmRElJcH0jyEnClg&q=site%3Amodelcarsmag.com+pro+mod+chassis&oq=site%3Amodelcarsmag.com+pro+mod+chassis&gs_lcp=Cgdnd3Mtd2l6EAM6CAgAEOoCEI8BOg4ILhCxAxDHARCjAhCTAjoLCC4QsQMQxwEQowI6CAgAELEDEIMBOgUIABCxAzoOCC4QsQMQgwEQxwEQowI6CAguELEDEIMBOgIILjoFCC4QsQM6AggAOgoIABCxAxCDARAKUI8eWOq0AWD6vwFoAXAAeACAAX6IAfodkgEFMTYuMjGYAQCgAQGqAQdnd3Mtd2l6sAEK&sclient=gws-wiz&ved=0ahUKEwjskZPJl_fuAhXnqlkKHfvuAwwQ4dUDCAw&uact=5

-

I have gotten some from Scenes Unlimited. They have a nice selection with dimensions listed on their site.

- 39,270 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Nice to see you rescuing this one. My Dad had a ‘61 and a ‘63? both 4 doors. And he had a ‘68 Biscayne 4 door that I took my drivers test in back in ‘77.?

-

‘54 Willys P/U

NOBLNG replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

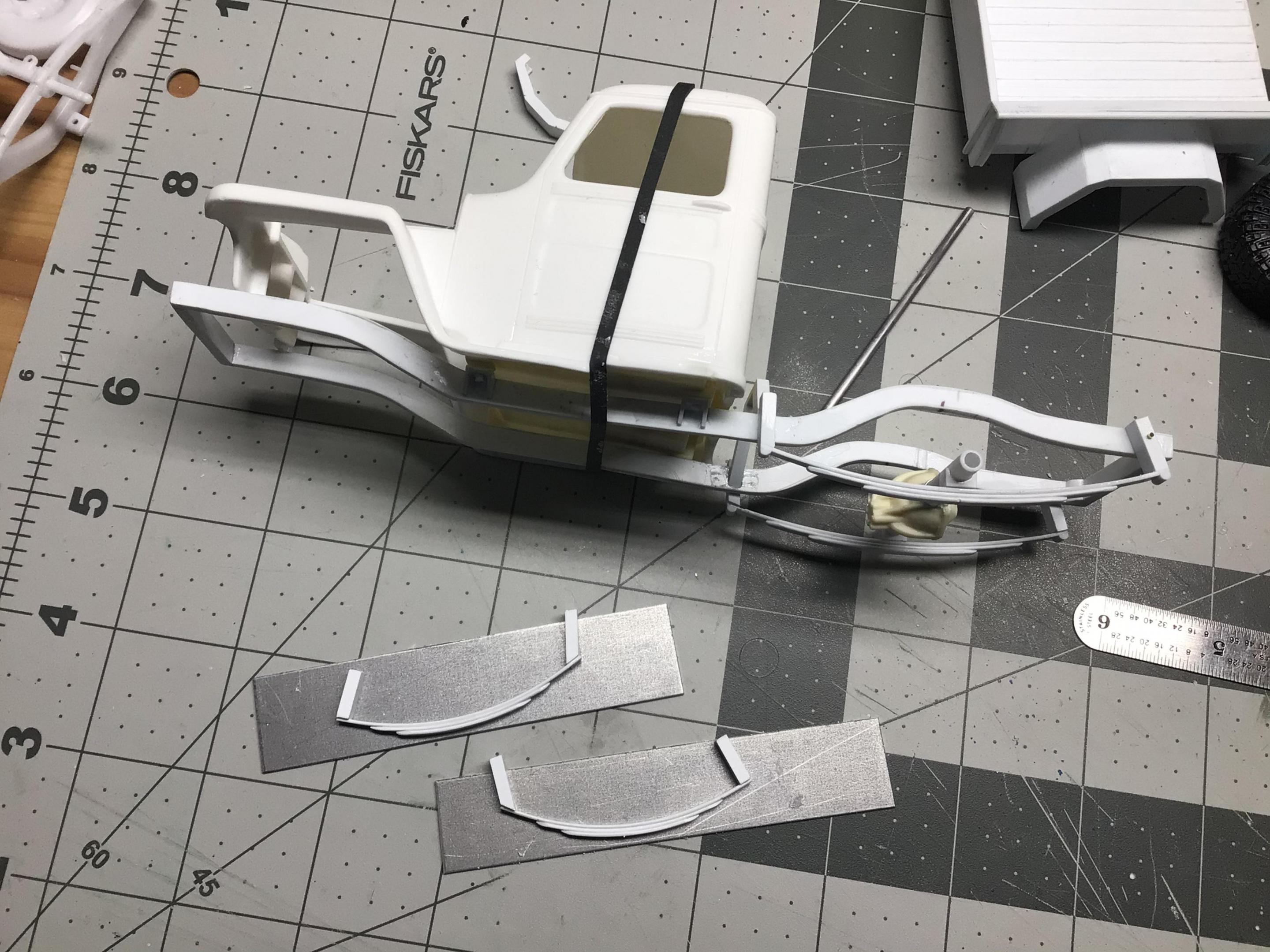

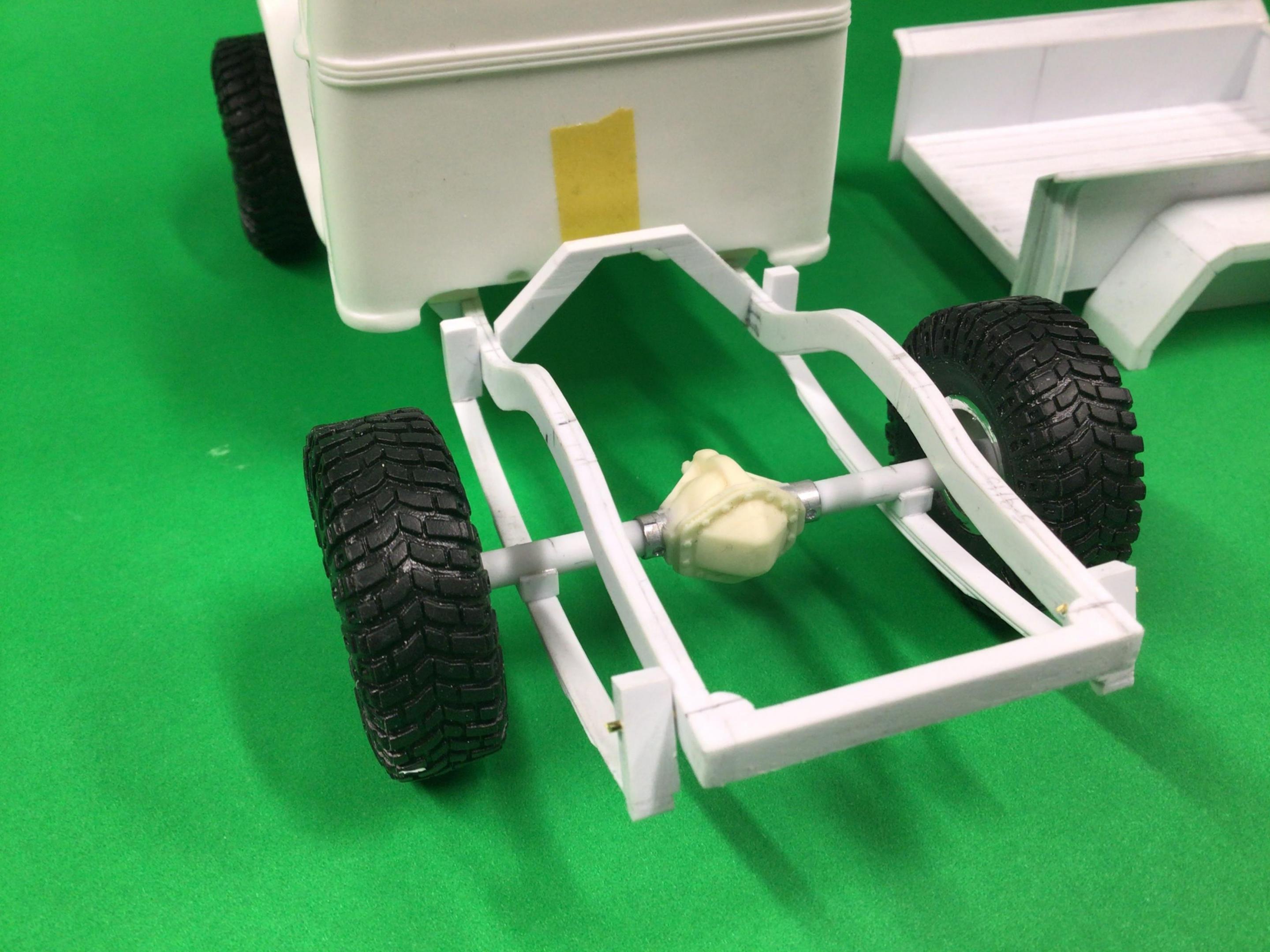

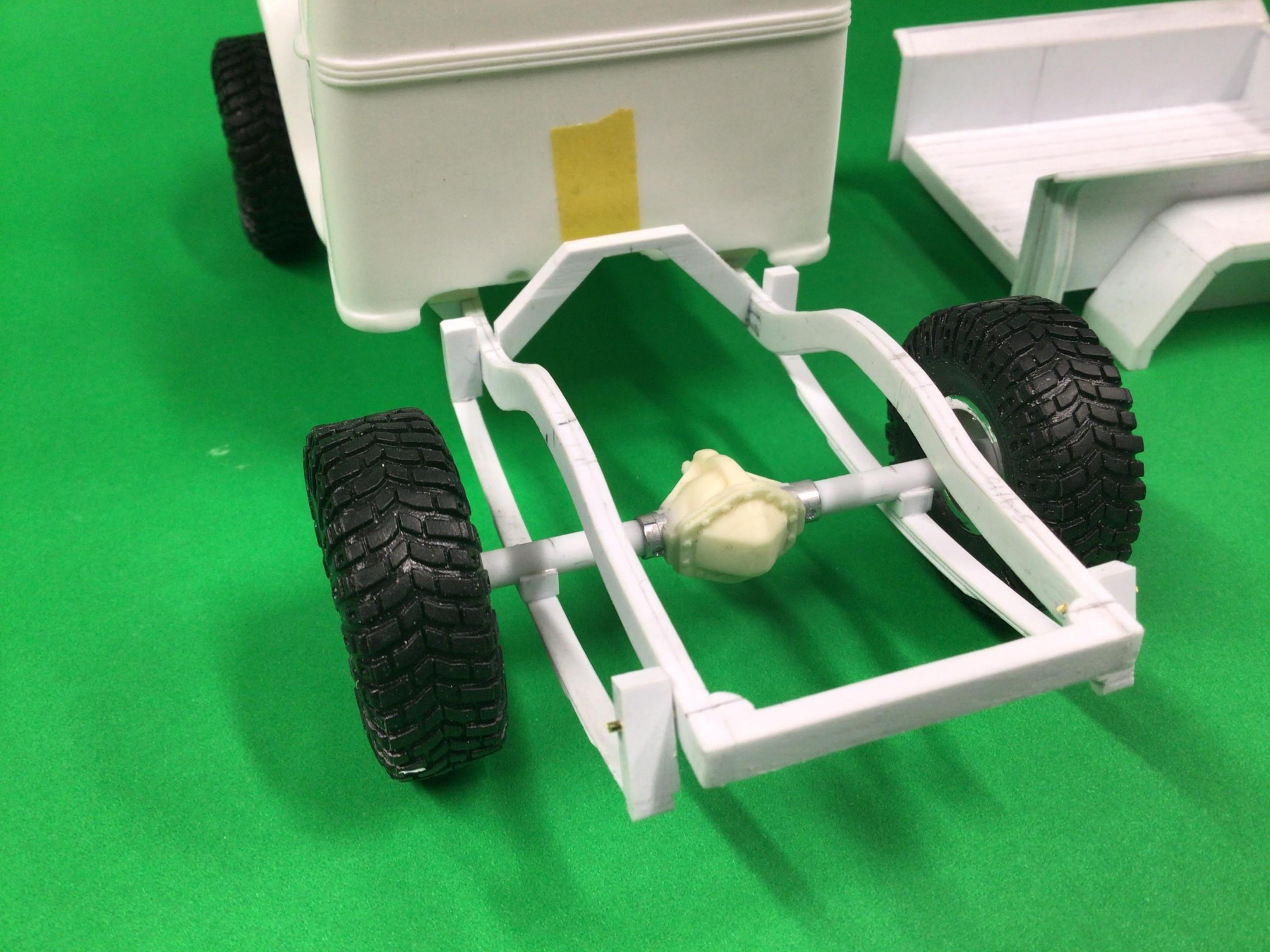

Well I finally got this one up on wheels. I wound up building differentials and springs from scratch. I found a really good tutorial on building leaf springs that Art Anderson put on here years ago. http://www.modelcarsmag.com/forums/topic/52798-leaf-springs/ Anyway, now that I have a baseline, I can tweak the mounting point locations a bit to level things up. I also need to shape or re-design them to make them more realistic. The differentials are not glued to the axle tubes yet and can be rotated to set the pinion angles once the drivetrain is in place. The front axle will likely be narrowed a bit yet. The stock trucks had quite a difference between front and rear track width. -

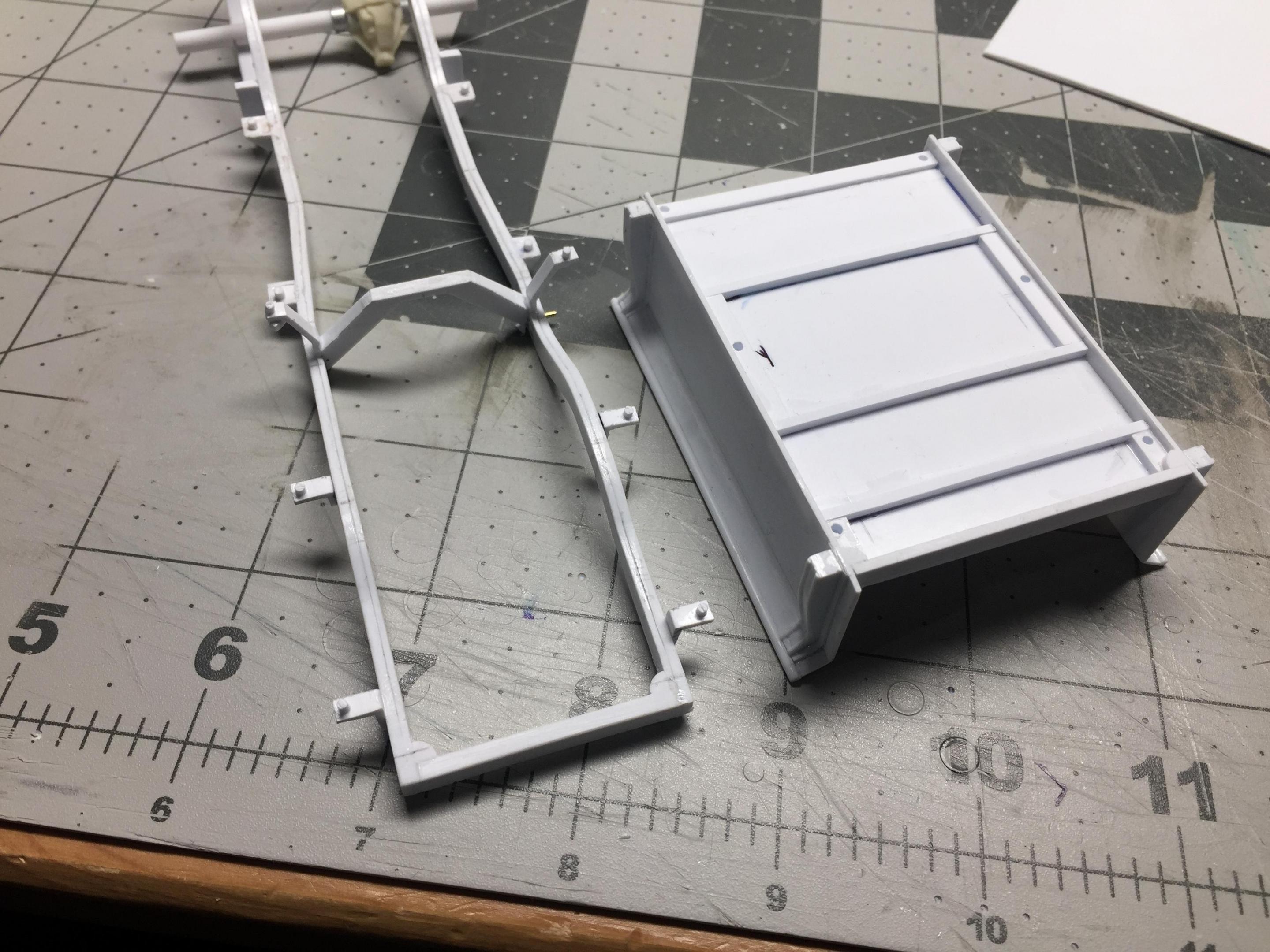

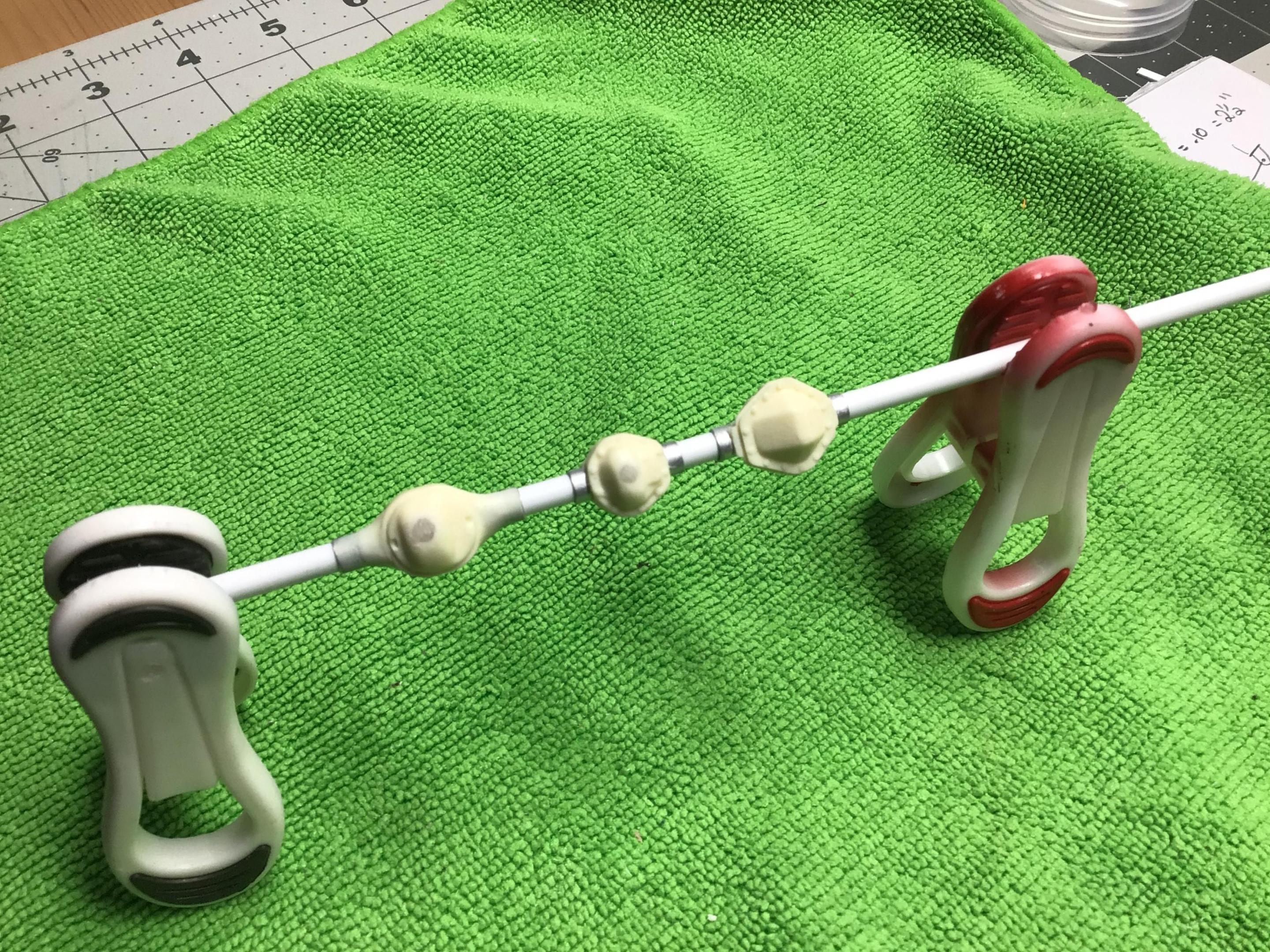

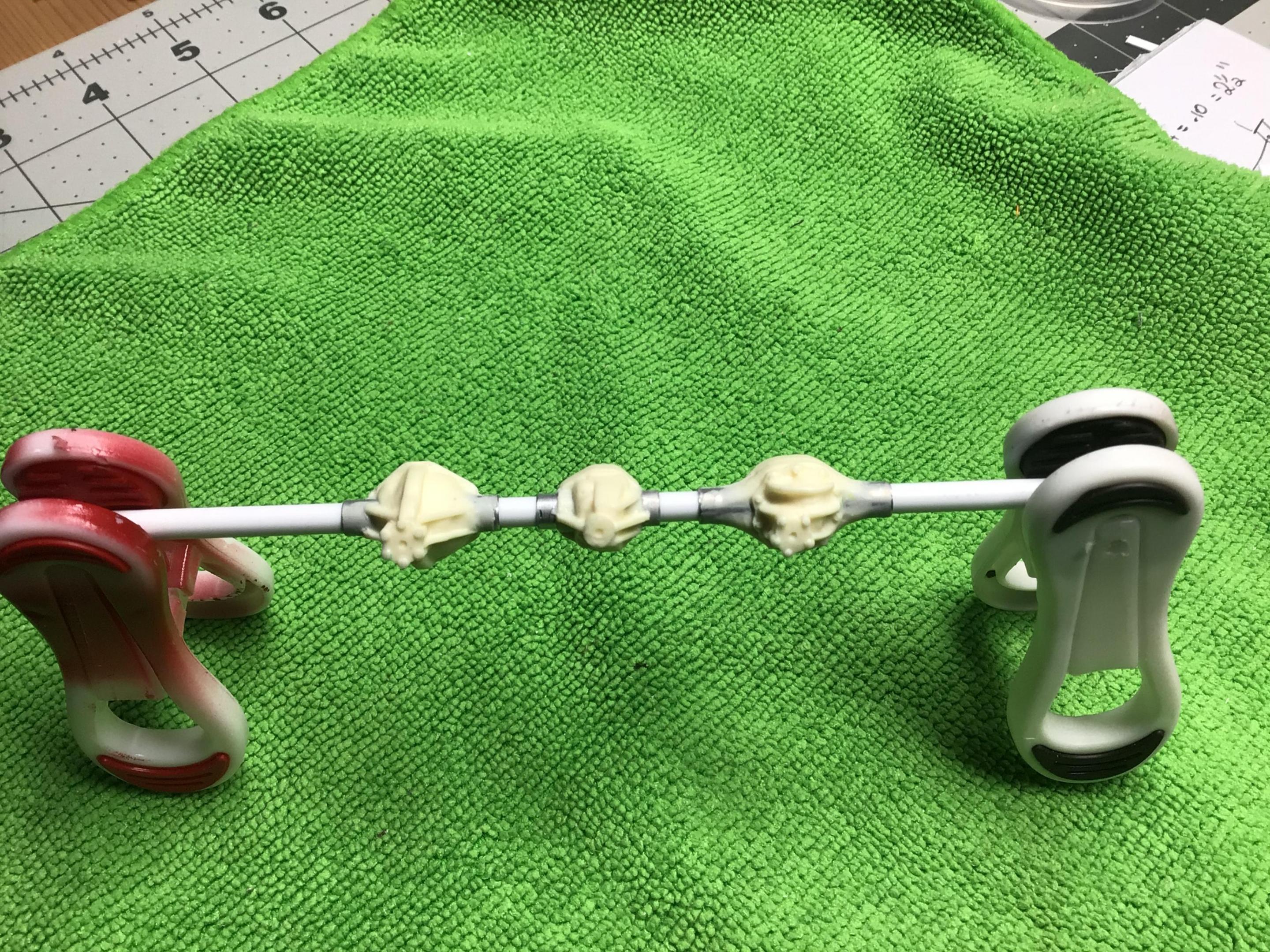

I posted this as a daily accomplishment, but I figure more folks would see it here. I want to do a few custom 4x4 builds in the future so I came up with this idea to minimize duplicating my efforts. I’ve modified the Mobius F100 center sections (Dana 44 and Ford 9”) to take a 3/16” aluminum tube. This is 4” in 1/25 scale or 3-3/4” in 1/24th, which I think is not too far off. I hate all the spindly little axles found in most kits! I also built a GM 14-bolt from scratch. I then made a mold so that I can cast the center section around the piece of tubing after temporarily plugging it with modeling clay to keep the resin out. A piece of .156 styrene tube will slide inside this and a piece of 3/32” rod (I use a coat hanger) for an axle. The diff can be left unglued until the rest of the drivetrain is in place to set the pinion angle. The F100 knuckles will be added to the front tube after being drilled for the metal axle.